FOLLOW THESE INSTALLATION STEPS, Continued

SPECIAL REQUIREMENTS FOR INTERCONNECTED SMOKE ALARMS

•Failure to meet any of the requirements for interconnecting Smoke Alarms could damage the units, and cause them to malfunction, removing your protection.

•AC and AC/DC Smoke Alarms can be interconnected. Under AC power, all units will alarm when one senses smoke. When power is interrupted, only the AC/DC units in the series will continue to send and receive signals. AC powered Smoke Alarms will not operate.

Interconnected units can provide earlier warning of fire than stand-alone units, especially if a fire starts in a remote area of the home. If any Smoke Alarm in the series senses smoke, all units will alarm. This Smoke Alarm can be interconnected with First Alert® Smoke Alarm Models SA4120, SA4121B, SA100B, SC9120B and BRK Electronics® Smoke Alarm Models 100S, 4120 series, 9120 series, 7010 series; BRK Electronics® Heat Alarm Models HD6135F, HD6135FB; Smoke/CO Alarm Model SC6120B.

Interconnect units within a single family residence only. Otherwise all households will experience unwanted alarms when you test any unit in the series. Interconnected units will only work if they are wired to compatible units and all requirements are met.

Interconnected units must meet ALL of the following requirements:

•A maximum of 18 units total may be interconnected (Maximum of 12 Smoke Alarms).

•The same fuse or circuit breaker must power all interconnected Smoke Alarms.

•The total length of wire interconnecting the units should be less than 1000 feet (305 meters). The interconnect wire should be #18 gauge or larger, rated at least 300V. If an interconnect wire is not already part of your household wiring, you will need to install one. This type of wire is commonly available at Hardware and Electrical Supply stores.

•All wiring must conform to all local electrical codes and Article 760 of the National Electrical Code (NFPA 70). Refer to NFPA 72 and/or your local building code for further connection requirements.

}

}

}

}

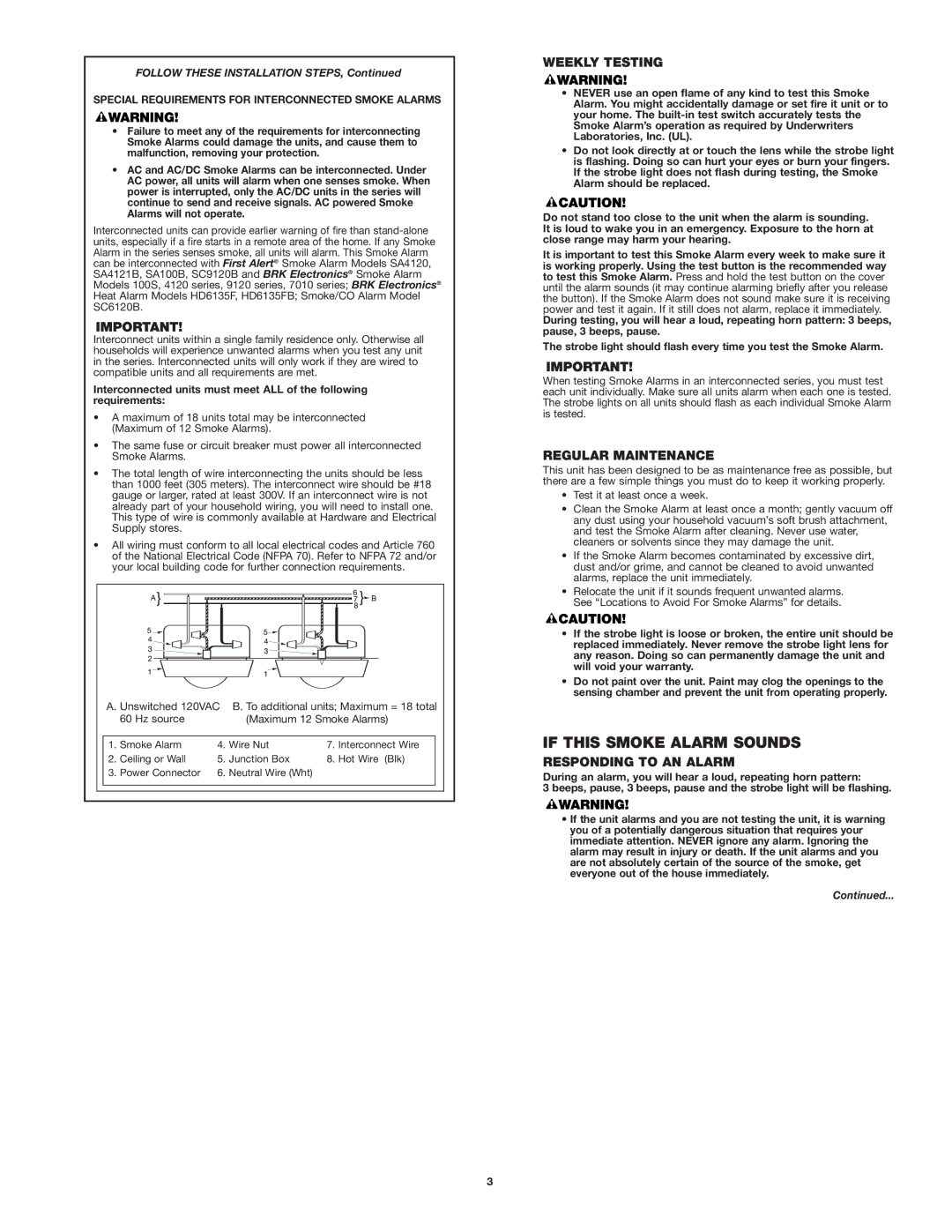

A. Unswitched 120VAC B. To additional units; Maximum = 18 total

| 60 Hz source | | (Maximum 12 Smoke Alarms) |

| | | | | |

1. | Smoke Alarm | 4. | Wire Nut | 7. | Interconnect Wire |

2. | Ceiling or Wall | 5. | Junction Box | 8. | Hot Wire (Blk) |

3. | Power Connector | 6. | Neutral Wire (Wht) | | |

| | | | | |

WEEKLY TESTING

•NEVER use an open flame of any kind to test this Smoke Alarm. You might accidentally damage or set fire it unit or to your home. The built-in test switch accurately tests the Smoke Alarm’s operation as required by Underwriters Laboratories, Inc. (UL).

•Do not look directly at or touch the lens while the strobe light is flashing. Doing so can hurt your eyes or burn your fingers. If the strobe light does not flash during testing, the Smoke Alarm should be replaced.

Do not stand too close to the unit when the alarm is sounding. It is loud to wake you in an emergency. Exposure to the horn at close range may harm your hearing.

It is important to test this Smoke Alarm every week to make sure it is working properly. Using the test button is the recommended way to test this Smoke Alarm. Press and hold the test button on the cover until the alarm sounds (it may continue alarming briefly after you release the button). If the Smoke Alarm does not sound make sure it is receiving power and test it again. If it still does not alarm, replace it immediately.

During testing, you will hear a loud, repeating horn pattern: 3 beeps, pause, 3 beeps, pause.

The strobe light should flash every time you test the Smoke Alarm.

When testing Smoke Alarms in an interconnected series, you must test each unit individually. Make sure all units alarm when each one is tested. The strobe lights on all units should flash as each individual Smoke Alarm is tested.

REGULAR MAINTENANCE

This unit has been designed to be as maintenance free as possible, but there are a few simple things you must do to keep it working properly.

•Test it at least once a week.

•Clean the Smoke Alarm at least once a month; gently vacuum off any dust using your household vacuum’s soft brush attachment, and test the Smoke Alarm after cleaning. Never use water, cleaners or solvents since they may damage the unit.

•If the Smoke Alarm becomes contaminated by excessive dirt, dust and/or grime, and cannot be cleaned to avoid unwanted alarms, replace the unit immediately.

•Relocate the unit if it sounds frequent unwanted alarms. See “Locations to Avoid For Smoke Alarms” for details.

•If the strobe light is loose or broken, the entire unit should be replaced immediately. Never remove the strobe light lens for any reason. Doing so can permanently damage the unit and will void your warranty.

•Do not paint over the unit. Paint may clog the openings to the sensing chamber and prevent the unit from operating properly.

IF THIS SMOKE ALARM SOUNDS

RESPONDING TO AN ALARM

During an alarm, you will hear a loud, repeating horn pattern:

3 beeps, pause, 3 beeps, pause and the strobe light will be flashing.

•If the unit alarms and you are not testing the unit, it is warning you of a potentially dangerous situation that requires your immediate attention. NEVER ignore any alarm. Ignoring the alarm may result in injury or death. If the unit alarms and you are not absolutely certain of the source of the smoke, get everyone out of the house immediately.

Continued...