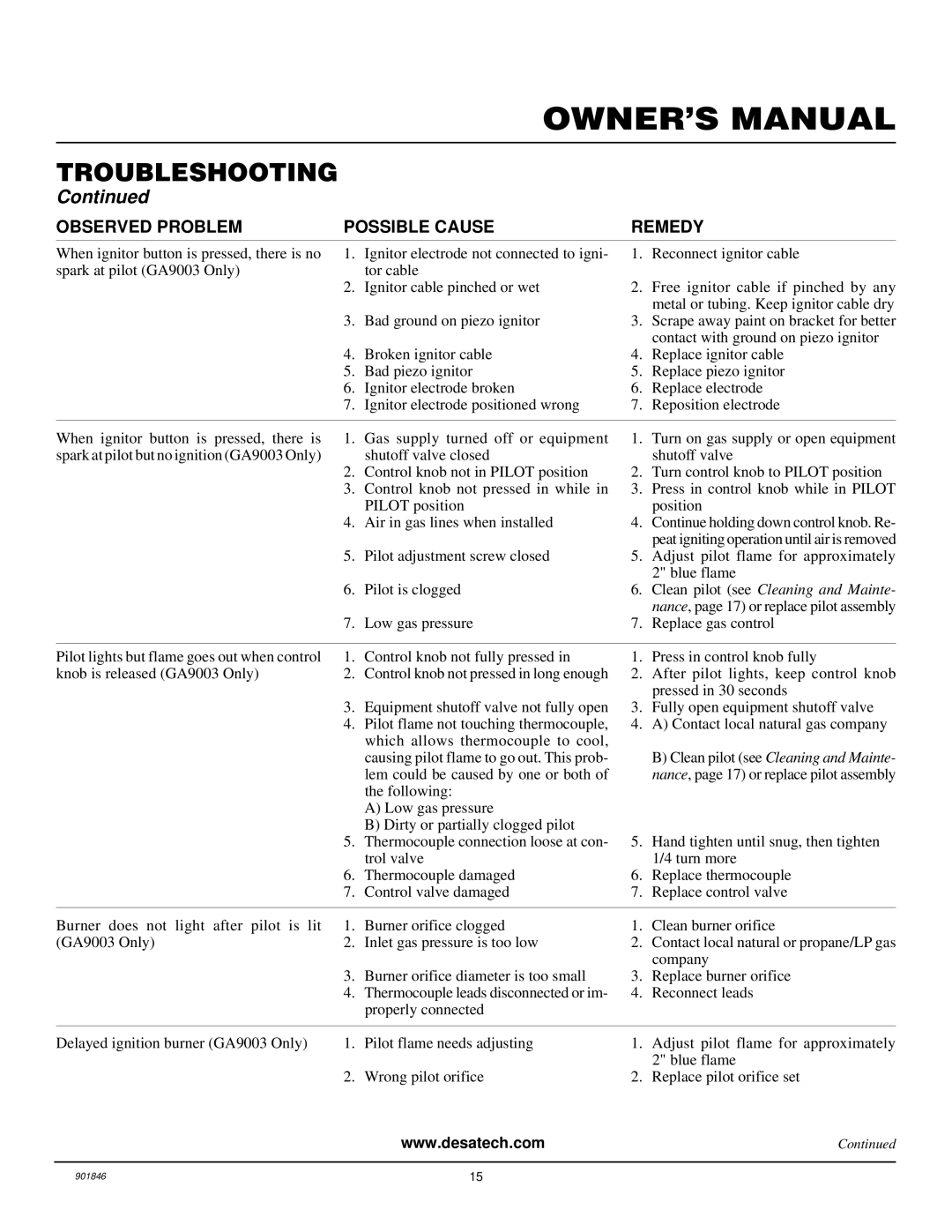

OWNER’S MANUAL

TROUBLESHOOTING

Continued

OBSERVED PROBLEM | POSSIBLE CAUSE | REMEDY | ||

When ignitor button is pressed, there is no | 1. | Ignitor electrode not connected to igni- | 1. | Reconnect ignitor cable |

spark at pilot (GA9003 Only) |

| tor cable |

|

|

| 2. | Ignitor cable pinched or wet | 2. | Free ignitor cable if pinched by any |

|

|

|

| metal or tubing. Keep ignitor cable dry |

| 3. | Bad ground on piezo ignitor | 3. | Scrape away paint on bracket for better |

|

|

|

| contact with ground on piezo ignitor |

| 4. | Broken ignitor cable | 4. | Replace ignitor cable |

| 5. | Bad piezo ignitor | 5. | Replace piezo ignitor |

| 6. | Ignitor electrode broken | 6. | Replace electrode |

| 7. | Ignitor electrode positioned wrong | 7. | Reposition electrode |

|

|

|

|

|

When ignitor button is pressed, there is | 1. | Gas supply turned off or equipment | 1. | Turn on gas supply or open equipment |

spark at pilot but no ignition (GA9003 Only) |

| shutoff valve closed |

| shutoff valve |

| 2. | Control knob not in PILOT position | 2. | Turn control knob to PILOT position |

| 3. | Control knob not pressed in while in | 3. | Press in control knob while in PILOT |

|

| PILOT position |

| position |

| 4. | Air in gas lines when installed | 4. | Continue holding down control knob. Re- |

|

|

|

| peat igniting operation until air is removed |

| 5. | Pilot adjustment screw closed | 5. | Adjust pilot flame for approximately |

|

|

|

| 2" blue flame |

| 6. | Pilot is clogged | 6. | Clean pilot (see Cleaning and Mainte- |

|

|

|

| nance, page 17) or replace pilot assembly |

| 7. | Low gas pressure | 7. | Replace gas control |

|

|

|

|

|

Pilot lights but flame goes out when control | 1. | Control knob not fully pressed in | 1. | Press in control knob fully |

knob is released (GA9003 Only) | 2. | Control knob not pressed in long enough | 2. | After pilot lights, keep control knob |

|

|

|

| pressed in 30 seconds |

| 3. | Equipment shutoff valve not fully open | 3. | Fully open equipment shutoff valve |

| 4. | Pilot flame not touching thermocouple, | 4. | A) Contact local natural gas company |

|

| which allows thermocouple to cool, |

|

|

|

| causing pilot flame to go out. This prob- |

| B) Clean pilot (see Cleaning and Mainte- |

|

| lem could be caused by one or both of |

| nance, page 17) or replace pilot assembly |

|

| the following: |

|

|

|

| A) Low gas pressure |

|

|

|

| B) Dirty or partially clogged pilot |

|

|

| 5. | Thermocouple connection loose at con- | 5. | Hand tighten until snug, then tighten |

|

| trol valve |

| 1/4 turn more |

| 6. | Thermocouple damaged | 6. | Replace thermocouple |

| 7. | Control valve damaged | 7. | Replace control valve |

|

|

|

|

|

Burner does not light after pilot is lit | 1. | Burner orifice clogged | 1. | Clean burner orifice |

(GA9003 Only) | 2. | Inlet gas pressure is too low | 2. | Contact local natural or propane/LP gas |

|

|

|

| company |

| 3. | Burner orifice diameter is too small | 3. | Replace burner orifice |

| 4. | Thermocouple leads disconnected or im- | 4. | Reconnect leads |

|

| properly connected |

|

|

|

|

|

|

|

Delayed ignition burner (GA9003 Only) | 1. | Pilot flame needs adjusting | 1. | Adjust pilot flame for approximately |

|

|

|

| 2" blue flame |

| 2. | Wrong pilot orifice | 2. | Replace pilot orifice set |

|

| www.desatech.com |

| Continued |

901846 | 15 |