VENTED NATURAL GAS LOGS

INSTALLATION

Continued

OPTIONAL GA9003 SERIES ON/OFF SAFETY VALVE/ PILOT KIT ASSEMBLY

For additional convenience and safety, or for propane/LP conversion, an optional ON/ OFF safety valve/pilot kit is available. See Accessories, page 17.

![]() WARNING: You must use a ON/OFF safety valve/pilot kit for propane/LP conversion.

WARNING: You must use a ON/OFF safety valve/pilot kit for propane/LP conversion.

Natural Gas Installation

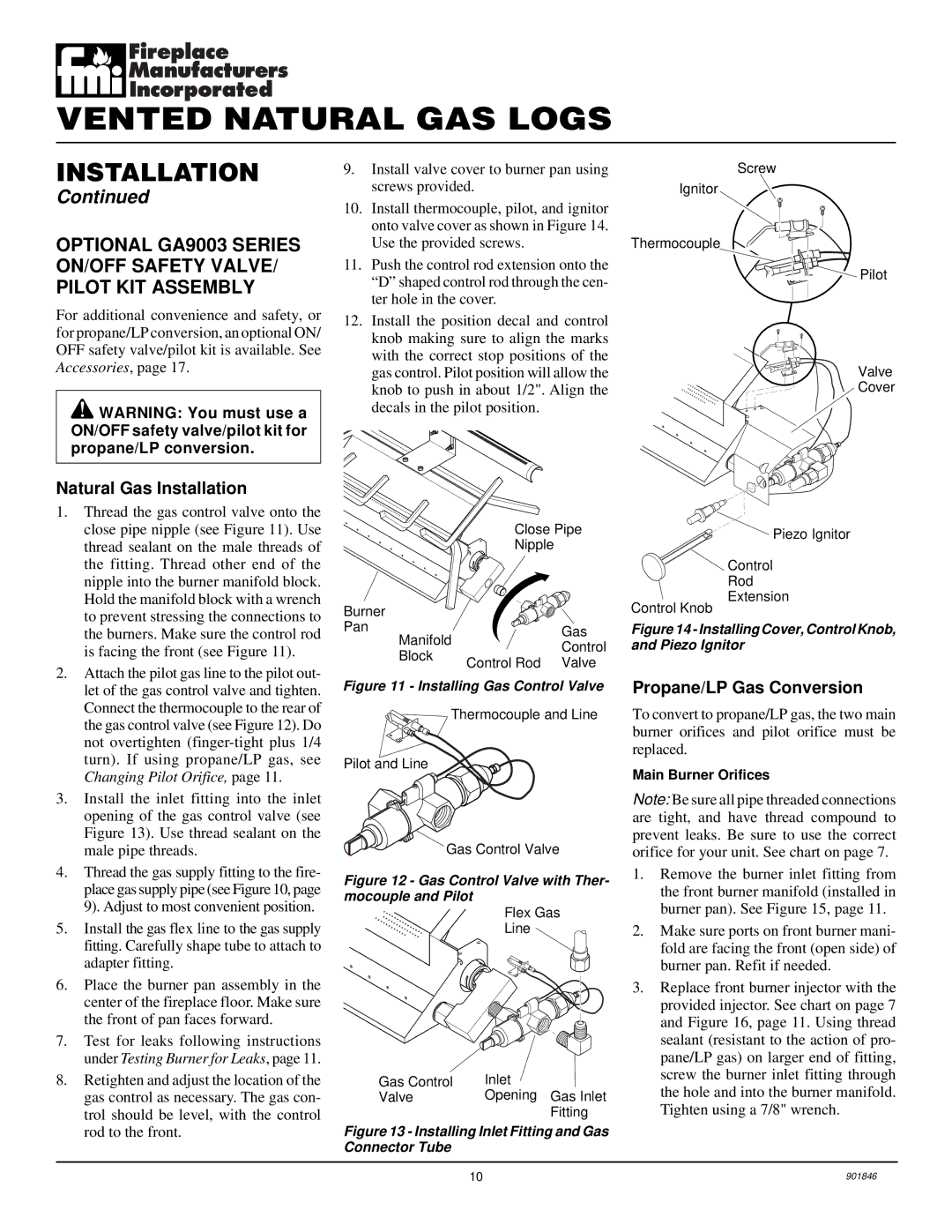

1.Thread the gas control valve onto the close pipe nipple (see Figure 11). Use thread sealant on the male threads of the fitting. Thread other end of the nipple into the burner manifold block. Hold the manifold block with a wrench to prevent stressing the connections to the burners. Make sure the control rod is facing the front (see Figure 11).

2.Attach the pilot gas line to the pilot out- let of the gas control valve and tighten. Connect the thermocouple to the rear of the gas control valve (see Figure 12). Do not overtighten

3.Install the inlet fitting into the inlet opening of the gas control valve (see Figure 13). Use thread sealant on the male pipe threads.

4.Thread the gas supply fitting to the fire- place gas supply pipe (see Figure 10, page 9). Adjust to most convenient position.

5.Install the gas flex line to the gas supply fitting. Carefully shape tube to attach to adapter fitting.

6.Place the burner pan assembly in the center of the fireplace floor. Make sure the front of pan faces forward.

7.Test for leaks following instructions under Testing Burner for Leaks, page 11.

8.Retighten and adjust the location of the gas control as necessary. The gas con- trol should be level, with the control rod to the front.

9.Install valve cover to burner pan using screws provided.

10.Install thermocouple, pilot, and ignitor onto valve cover as shown in Figure 14. Use the provided screws.

11.Push the control rod extension onto the “D” shaped control rod through the cen- ter hole in the cover.

12.Install the position decal and control knob making sure to align the marks with the correct stop positions of the gas control. Pilot position will allow the knob to push in about 1/2". Align the decals in the pilot position.

| Close Pipe | ||

| Nipple |

| |

Burner |

|

| |

Pan |

| Gas | |

Manifold |

| ||

| Control | ||

Block |

| ||

Control Rod | Valve | ||

| |||

Figure 11 - Installing Gas Control Valve

Thermocouple and Line

Pilot and Line

Gas Control Valve

Figure 12 - Gas Control Valve with Ther- mocouple and Pilot

Flex Gas

Line

Gas Control | Inlet |

Valve | Opening Gas Inlet |

| Fitting |

Figure 13 - Installing Inlet Fitting and Gas Connector Tube

Screw

Ignitor

Thermocouple

Pilot

Valve

Cover

Piezo Ignitor

Control

Rod

Extension

Control Knob

Figure 14 - Installing Cover, Control Knob, and Piezo Ignitor

Propane/LP Gas Conversion

To convert to propane/LP gas, the two main burner orifices and pilot orifice must be replaced.

Main Burner Orifices

Note: Be sure all pipe threaded connections are tight, and have thread compound to prevent leaks. Be sure to use the correct orifice for your unit. See chart on page 7.

1.Remove the burner inlet fitting from the front burner manifold (installed in burner pan). See Figure 15, page 11.

2.Make sure ports on front burner mani- fold are facing the front (open side) of burner pan. Refit if needed.

3.Replace front burner injector with the provided injector. See chart on page 7 and Figure 16, page 11. Using thread sealant (resistant to the action of pro- pane/LP gas) on larger end of fitting, screw the burner inlet fitting through the hole and into the burner manifold. Tighten using a 7/8" wrench.

10 | 901846 |