30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with Sealed Top Burners)

Before Starting

Tools You Will Need

For leveling legs and Anti-Tip Bracket:

•Adjustable wrench or channel lock pliers ![]()

•5/16" Nutdriver or Flat Head Screw Driver ![]()

•Electric Drill & 1/8" Diameter Drill Bit (5/32" Masonry Drill Bit if installing in concrete)

For gas supply connection:

•Pipe wrench

For burner flame adjustment:

•Phillips head ![]() and

and ![]()

For gas conversion (LP/Propane or Natural):

•Open end wrench - 1/2"

Additional Materials You Will Need

•Gas line ![]()

![]()

![]()

•Pipe joint sealant that resists action of LP/Propane gas

•A new flexible metal appliance conduit (1/2" NPT x 3/4" or 1/2" I.D.) must be design certified by CSA International. Because solid pipe restricts moving the range we recommend using a new flexible conduit (4 to 5 foot length) for each new installation and additional reinstallations.

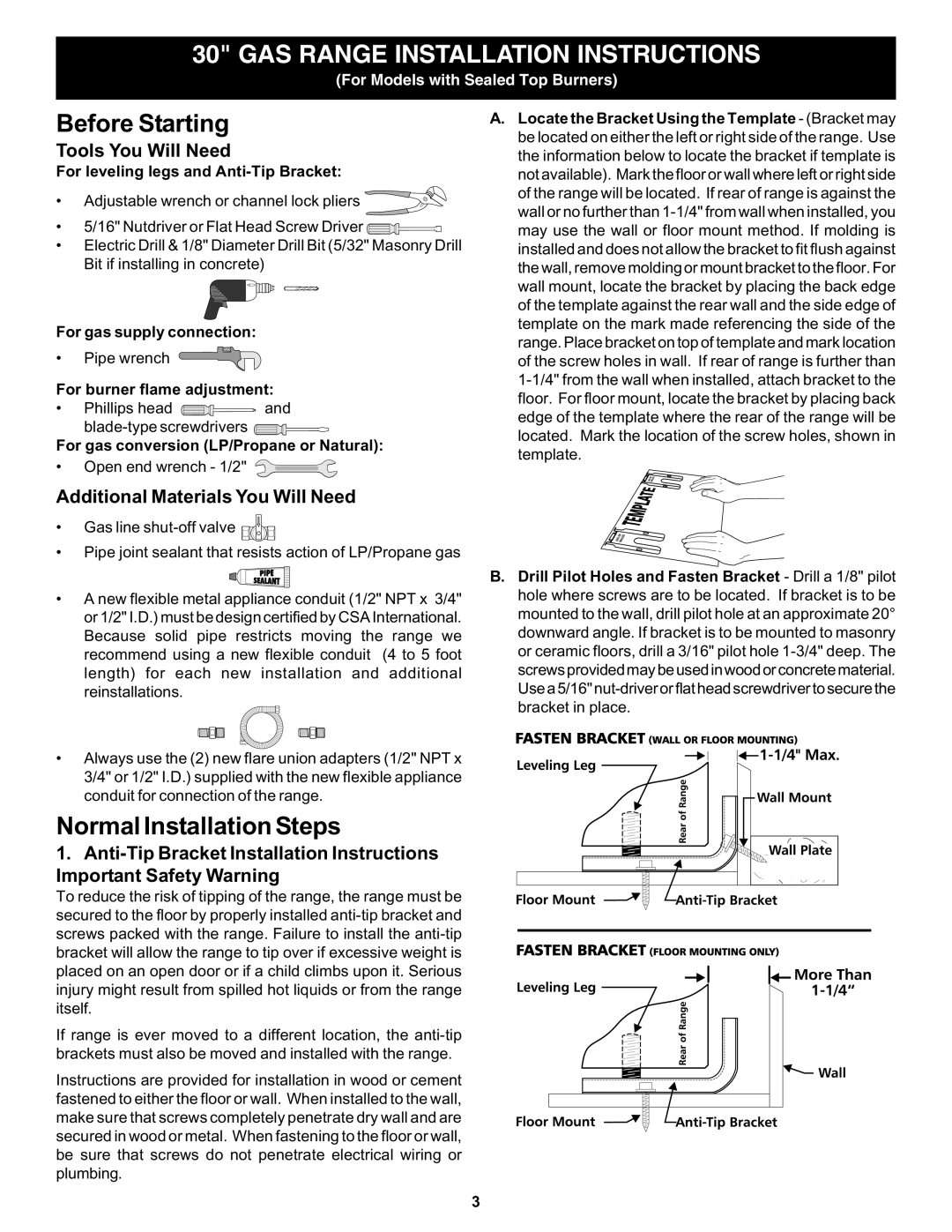

A.Locate the Bracket Using the Template - (Bracket may be located on either the left or right side of the range. Use the information below to locate the bracket if template is not available). Mark the floor or wall where left or right side of the range will be located. If rear of range is against the wall or no further than

B.Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot hole where screws are to be located. If bracket is to be mounted to the wall, drill pilot hole at an approximate 20° downward angle. If bracket is to be mounted to masonry or ceramic floors, drill a 3/16" pilot hole

•Always use the (2) new flare union adapters (1/2" NPT x 3/4" or 1/2" I.D.) supplied with the new flexible appliance conduit for connection of the range.

Normal Installation Steps

1.

To reduce the risk of tipping of the range, the range must be secured to the floor by properly installed

If range is ever moved to a different location, the

Instructions are provided for installation in wood or cement fastened to either the floor or wall. When installed to the wall, make sure that screws completely penetrate dry wall and are secured in wood or metal. When fastening to the floor or wall, be sure that screws do not penetrate electrical wiring or plumbing.

3