FPH55, FPH55-2 specifications

The Frymaster FPH55 and FPH55-2 are state-of-the-art commercial fryers that exemplify innovation in culinary technology. Designed to meet the demanding needs of busy kitchens, they provide efficient frying capabilities while ensuring energy savings and consistent product quality.One of the standout features of the Frymaster FPH55 is its advanced frying oil management system. This system includes built-in oil filtration, which provides automatic filtering that extends the life of the oil, reducing costs and improving the quality of fried foods. The patented filtration technology allows operators to maintain an optimal frying environment, ensuring that each batch of food is crispy and delicious without compromising on flavor.

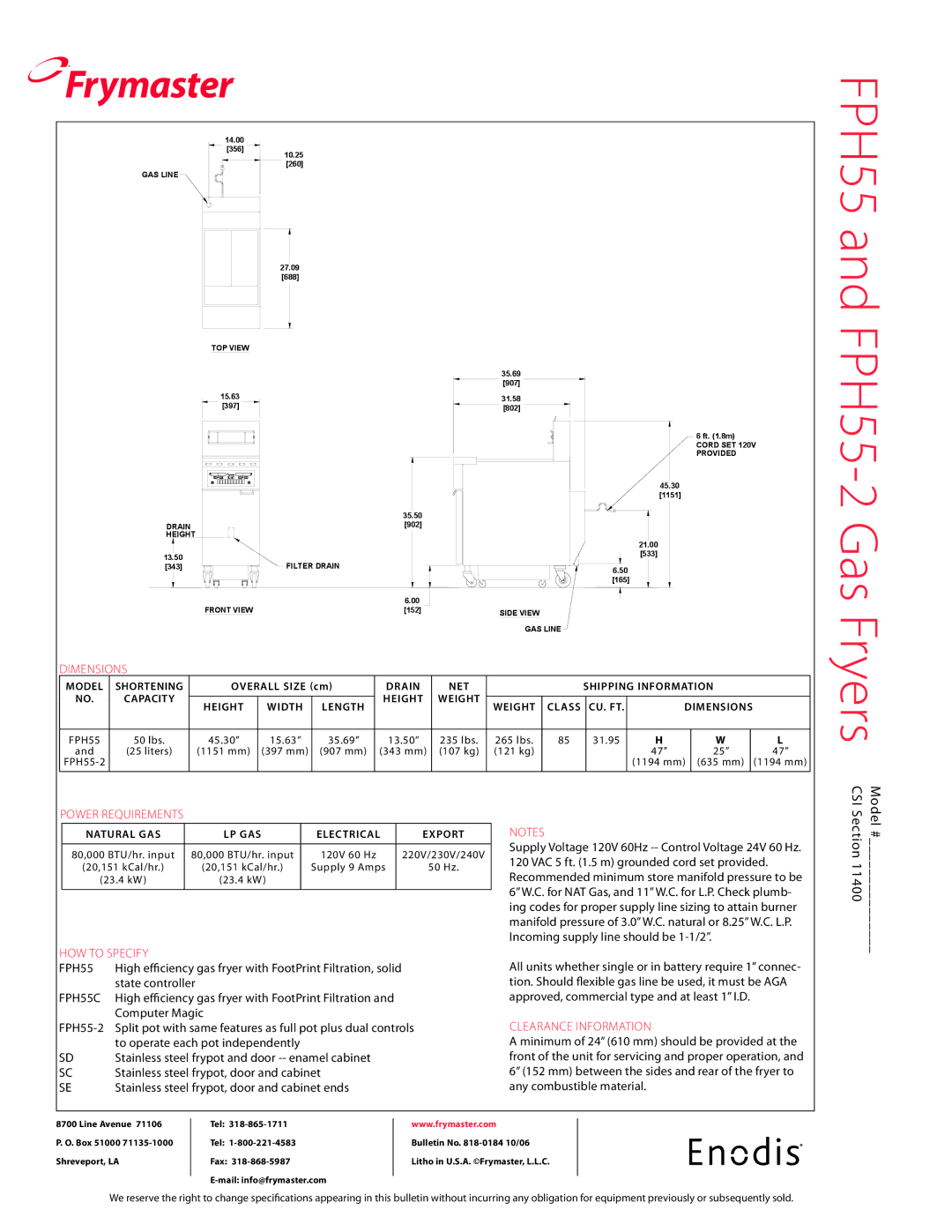

In terms of capacity, the FPH55 and FPH55-2 are designed to handle high volumes of food, making them ideal for restaurants, food trucks, and catering operations. The FPH55 boasts a single frypot with a capacity of 50 lbs, while the FPH55-2 features two frypots, allowing simultaneous frying of multiple food items. This dual functionality enhances productivity and maximizes output, catering to high demand with ease.

Both models are equipped with Energy Smart technology, which ensures lower energy consumption while maintaining high performance. This feature not only contributes to a more eco-friendly operation but also reduces utility costs for the business. The intuitive control system enhances user experience, allowing chefs to easily adjust frying times and temperatures for various types of foods.

Safety is another key characteristic of the Frymaster FPH55 and FPH55-2. They are built with robust safety features including a removable stainless steel fryer cabinet, ensuring easy cleaning and maintenance. Additionally, the fryers are designed to minimize oil splatter, reducing the risk of burns and injuries in the kitchen.

Compact and ergonomic, these fryers are designed to fit seamlessly into kitchen environments while maintaining ease of access for operators. Their sleek design is complemented by durable construction, built to withstand the rigors of a busy kitchen.

Overall, the Frymaster FPH55 and FPH55-2 represent the pinnacle of frying technology and efficiency, making them essential tools for any commercial kitchen looking to elevate their frying capabilities. With a focus on oil management, energy efficiency, capacity, and safety, these fryers ensure that chefs can deliver high-quality results time and time again.