MJ35G specifications

The Frymaster MJ35G is an innovative commercial deep fryer designed to meet the demands of busy kitchens while ensuring perfect frying results every time. This model is particularly renowned for its efficiency, reliability, and advanced features that cater to high-volume frying operations.One of the standout features of the Frymaster MJ35G is its innovative oil filtration system. The built-in filtration enables quick and easy oil maintenance, which extends the life of the oil and enhances food quality. This system allows operators to filter oil overnight, reducing waste and saving on oil costs, making it not only environmentally friendly but also economically viable.

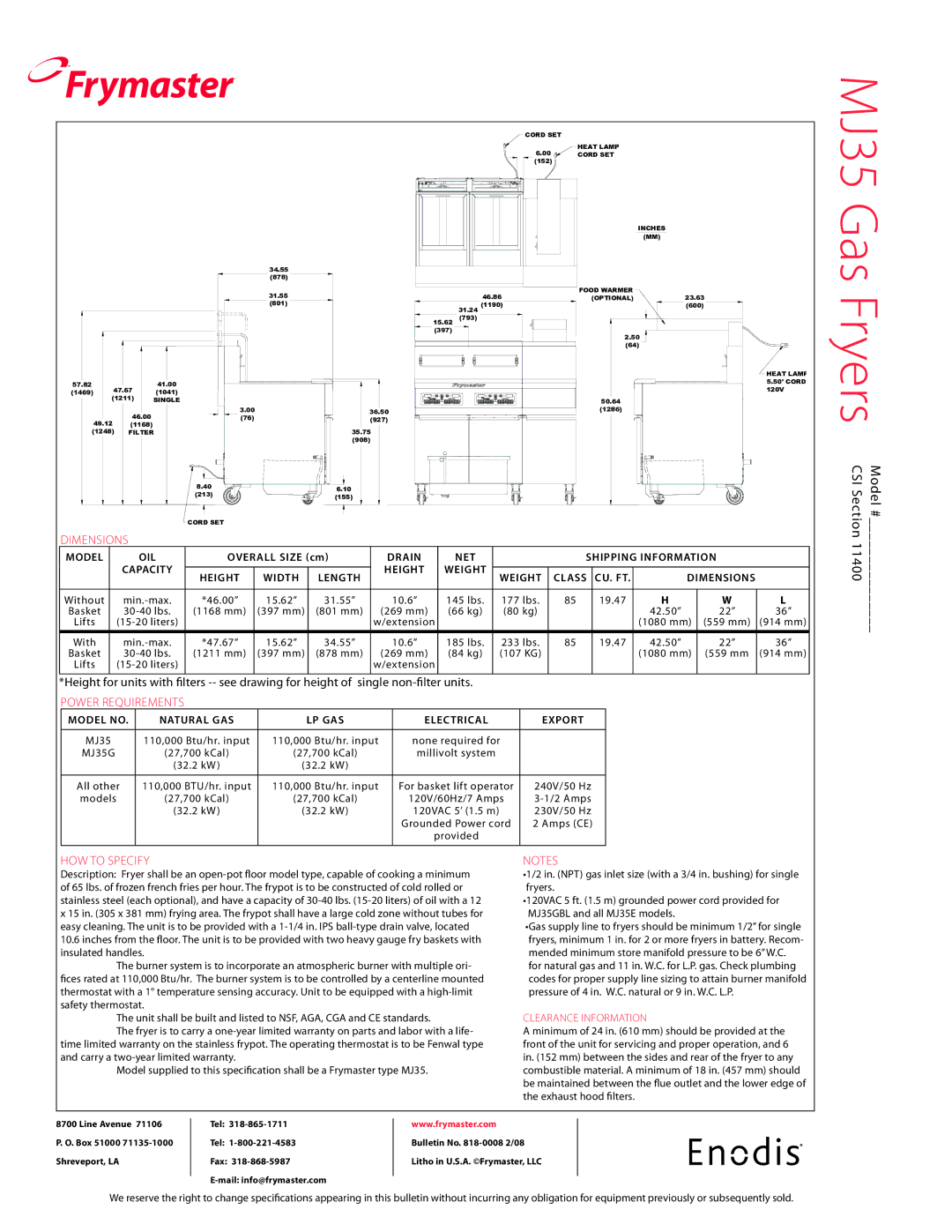

The Frymaster MJ35G comes equipped with a high-efficiency fryer design that utilizes gas as its power source, boasting an impressive output. The model features a powerful heating system that guarantees rapid heat recovery time, allowing for consistent frying without extended waiting periods. This is especially important in high-volume operations where speed is crucial.

Another significant characteristic of the MJ35G is its programmable controls. These controls enable operators to set precise cooking times and temperatures for various foods, ensuring consistency and reducing the potential for human error. The user-friendly interface provides easy navigation for staff, contributing to seamless kitchen operations.

The Frymaster MJ35G is engineered with safety in mind. It includes features such as a temperature limiting device and a high-temperature shut-off, which prevent overheating, thereby safeguarding both the equipment and the kitchen staff. Additionally, the fryer is equipped with durable, corrosion-resistant materials that ensure longevity even in demanding environments.

A notable aspect of this fryer is its compact design, allowing it to fit into kitchens with limited space. Despite its smaller footprint, it retains a significant oil capacity, accommodating various frying needs from appetizers to main courses.

In summary, the Frymaster MJ35G is a top-tier fryer suitable for commercial use, featuring advanced oil filtration systems, programmable controls, excellent heating performance, safety mechanisms, and durable construction. This combination of features ensures high-quality fried products, operational efficiency, and cost-effectiveness, making it an excellent investment for any culinary establishment looking to elevate its frying capabilities.