![]() Frymaster™®

Frymaster™®

MJ45 and MJ45-2 Gas Fryers

Project

Item

Quantity

CSI Section 11400

Approval

Date

MJ45 and

Models |

|

|

|

|

|

|

|

| ||

MJ45 |

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Standard Features | Full size basket in lieu of twin | ||||

|

|

|

|

| ||||||

|

|

|

|

| • | baskets | ||||

|

|

|

|

| • Durable centerline thermostat | Fryer’s Friend | ||||

|

|

|

|

| • | |||||

|

|

|

|

| anticipating action, reduced temperature | Fishplate | ||||

|

|

|

|

| overshoot | Piezo ignitor | ||||

|

|

|

|

| • Deep cold zone, | Shortening melt cycle control | ||||

|

|

|

|

| 3/4” x 48” (19 x 1219 mm) quick | |||||

|

|

|

|

| • Master Jet burner, no burner tube radi- | |||||

|

|

|

|

| disconnect with gas line and | |||||

|

|

|

|

| ants to burn out, no cleaning or adjusting | |||||

|

|

|

|

| adapter | |||||

|

|

|

|

| air shutters | |||||

|

|

|

|

| 3/4” x 36” (19 x 914 mm) quick | |||||

|

|

|

|

| • Rounded corners for | |||||

|

|

|

|

| disconnect with gas line and | |||||

|

|

|

|

| look | |||||

|

|

|

|

| adapter | |||||

|

|

|

|

| Options & Accessories | |||||

|

|

|

|

| Automatic basket lifts | |||||

|

|

|

|

| Computer, basket lift timer, digital or | Stainless steel apron drain with | ||||

|

|

|

|

| basket (interchangeable right or | |||||

|

|

|

|

| solid state controller | |||||

|

|

|

|

| left side) | |||||

|

|

|

|

| Electronic ignition (must use one of | |||||

|

|

|

|

|

| |||||

|

|

|

|

| the above controllers) |

| ||||

|

|

|

|

| Frypot cover |

| ||||

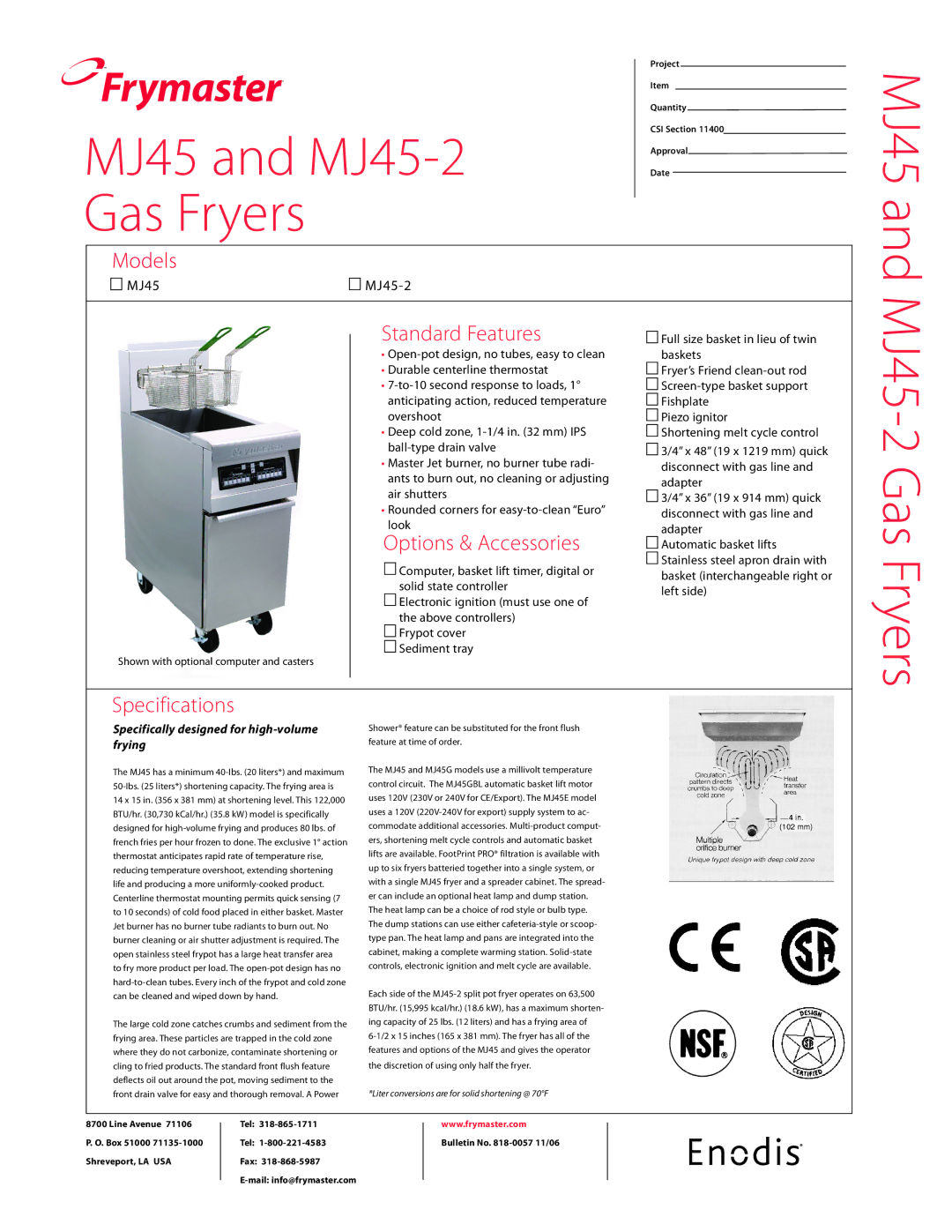

Shown with optional computer and casters |

| Sediment tray |

| |||||||

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specifications |

|

|

|

|

|

|

|

| ||

Specifically designed for | Shower® feature can be substituted for the front flush |

| ||||||||

frying |

|

| feature at time of order. |

| ||||||

The MJ45 has a minimum | The MJ45 and MJ45G models use a millivolt temperature |

| ||||||||

control circuit. The MJ45GBL automatic basket lift motor |

| |||||||||

14 x 15 in. (356 x 381 mm) at shortening level. This 122,000 | uses 120V (230V or 240V for CE/Export). The MJ45E model |

| ||||||||

BTU/hr. (30,730 kCal/hr.) (35.8 kW) model is specifically | uses a 120V |

| ||||||||

designed for | commodate additional accessories. |

| ||||||||

french fries per hour frozen to done. The exclusive 1° action | ers, shortening melt cycle controls and automatic basket |

| ||||||||

thermostat anticipates rapid rate of temperature rise, | lifts are available. FootPrint PRO® filtration is available with |

| ||||||||

reducing temperature overshoot, extending shortening | up to six fryers batteried together into a single system, or |

| ||||||||

life and producing a more | with a single MJ45 fryer and a spreader cabinet. The spread- |

| ||||||||

Centerline thermostat mounting permits quick sensing (7 | er can include an optional heat lamp and dump station. |

| ||||||||

to 10 seconds) of cold food placed in either basket. Master | The heat lamp can be a choice of rod style or bulb type. |

| ||||||||

Jet burner has no burner tube radiants to burn out. No | The dump stations can use either |

| ||||||||

burner cleaning or air shutter adjustment is required. The | type pan. The heat lamp and pans are integrated into the |

| ||||||||

open stainless steel frypot has a large heat transfer area | cabinet, making a complete warming station. |

| ||||||||

to fry more product per load. The | controls, electronic ignition and melt cycle are available. |

| ||||||||

|

|

|

|

|

| |||||

can be cleaned and wiped down by hand. | Each side of the |

| ||||||||

|

|

|

|

| BTU/hr. (15,995 kcal/hr.) (18.6 kW), has a maximum shorten- |

| ||||

The large cold zone catches crumbs and sediment from the | ing capacity of 25 lbs. (12 liters) and has a frying area of |

| ||||||||

frying area. These particles are trapped in the cold zone |

| |||||||||

where they do not carbonize, contaminate shortening or | features and options of the MJ45 and gives the operator |

| ||||||||

cling to fried products. The standard front flush feature | the discretion of using only half the fryer. |

| ||||||||

deflects oil out around the pot, moving sediment to the |

|

|

|

|

|

| ||||

front drain valve for easy and thorough removal. A Power | *Liter conversions are for solid shortening @ 70°F |

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

8700 Line Avenue 71106 |

|

| Tel: |

|

| www.frymaster.com |

|

|

| |

|

|

|

| |||||||

P. O. Box 51000 |

|

| Tel: |

|

| Bulletin No. |

|

|

| |

Shreveport, LA USA |

|

| Fax: |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||