1200, 400 specifications

The GBC 400,1200 is a cutting-edge device that has rapidly gained attention in various industrial sectors due to its impressive features and advanced technologies. This model stands as a testament to the fusion of innovation and practicality, making it a preferred choice for professionals seeking reliability and performance.One of the standout features of the GBC 400,1200 is its exceptional processing speed. With rapid processing capabilities, this device is designed to handle large volumes of data efficiently, making it suitable for industries such as manufacturing, logistics, and information systems. The advanced processor ensures that operations are performed seamlessly, minimizing downtime and enhancing productivity.

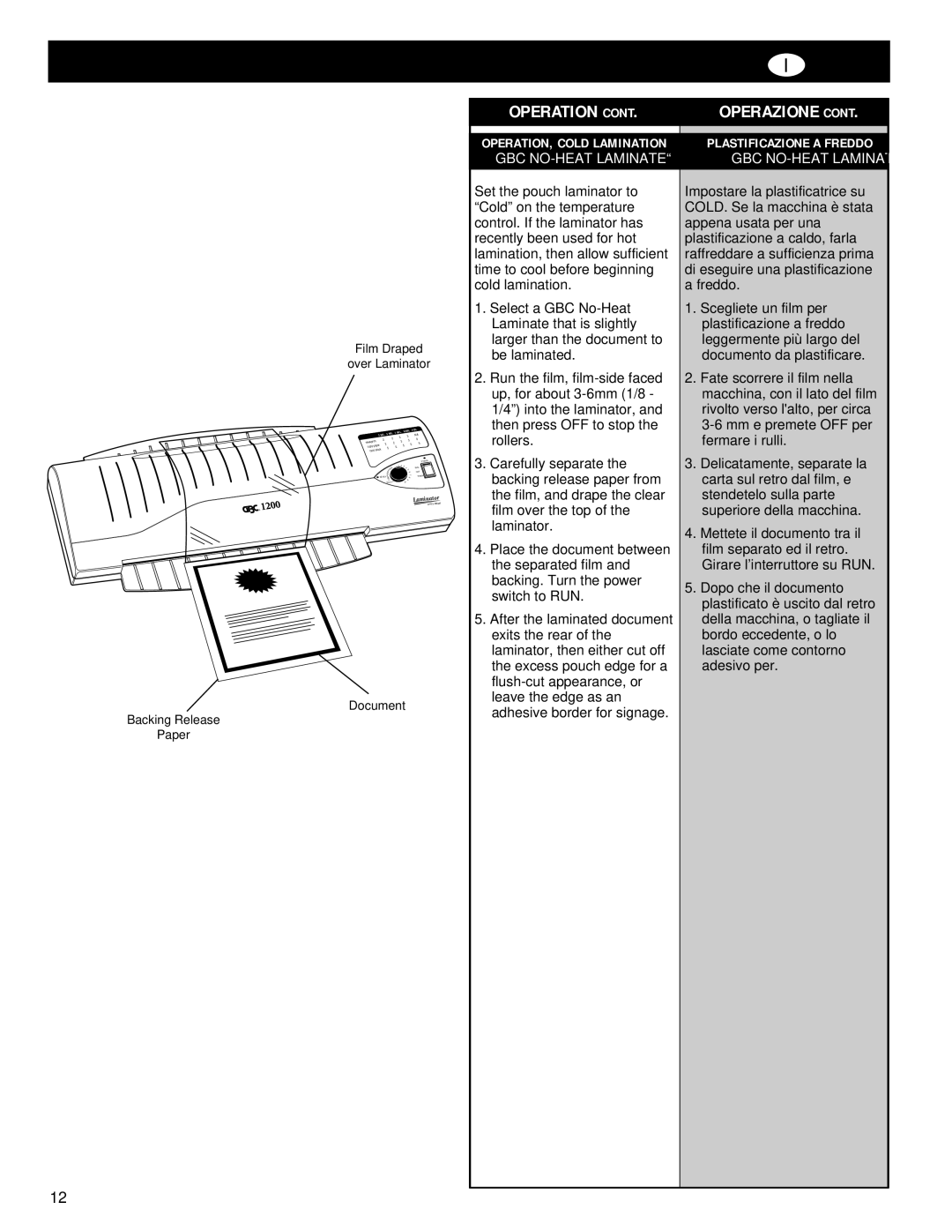

In terms of design, the GBC 400,1200 boasts an ergonomic layout that promotes ease of use. The user-friendly interface allows operators to navigate through various functionalities effortlessly. This design consideration is crucial in environments where time is of the essence and ease of operation can significantly impact overall efficiency.

The technology integrated into the GBC 400,1200 is noteworthy. It employs the latest communication protocols, allowing for robust connectivity with other devices and systems. This capability is particularly beneficial in connected environments where data sharing and system integration are paramount. The ability to synchronize with existing infrastructure means lower transitional costs and enhanced operational synergy.

Efficiency is further augmented through the GBC 400,1200’s energy-saving features. The device is designed to operate with minimal power consumption without compromising performance. This not only helps in reducing operational costs but also aligns with increasing global emphasis on sustainability and eco-friendly practices.

Moreover, the GBC 400,1200 is built with durability in mind. Constructed from high-quality materials, it is resistant to wear and tear, making it suitable for various challenging environments. The design meets industry standards for reliability, ensuring that the device can perform consistently over long periods.

Another significant characteristic of the GBC 400,1200 is its scalability. Whether a small enterprise or a large corporation, the device can be adapted to meet varying requirements. This scalability fosters growth, as additional features and capabilities can be integrated as needed, ensuring that the technology continues to meet evolving business demands.

In conclusion, the GBC 400,1200 is a versatile and powerful device that combines speed, efficiency, and durability. Its advanced technology and user-friendly design make it a valuable asset for any organization looking to enhance productivity and operational efficiency. With its commitment to sustainability and adaptability, the GBC 400,1200 not only meets current needs but also positions businesses to thrive in the future.