GE SmartWater™

GE Model FQSLF Replacement Filter / Filtre de remplacement, modèle de GE FQSLF /

Filtro de recambio, modelo de GE FQSLF

Your new GE water dispenser/icemaker water replacement filter gives you up to 1200 gallons or 6 months of great-tasting water. Filter should be changed after 6 months of use.

Votre nouveau filtre de remplacement à eau GE pour générateur de glaçons procure jusqu’à 4 542 litres (1 200 gallons) d’une eau d’excellente qualité équivalant à environ 6 mois d’utilisation. On devrait changer le filtre après 6 mois d’utilisation.

Su nuevo filtro de reemplazo GE para el dispensador de agua/máquina de hielos le ofrece hasta 1,200 galones o 6 meses de agua de excelente sabor. El filtro deberá cambiarse después de 6 meses de uso.

WARNING

AVERTISSEMENT

ADVERTENCIA

Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

Small parts remaining after the installation could be a choke hazard. Discard safely.

Ne pas utiliser ce produit sans une désinfection adéquate avant ou après le système, avec d’eau de qualité inconnue ou microbiologiquement polluée.

Les petites pièces non utilisées après l’installation peuvent susciter un risque d’étouffement pour les jeunes enfants. Veiller à les éliminer.

No usar con agua que sea microbiológicamente insegura o de calidad desconocida sin desinfectarla como es debido antes o después del sistema.

Cerciórese de que el agua se desinfecta adecuadamente, ya sea a la entrada o a la salida del filtro.

Las pequeñas piezas que sobran después de la instalación pueden constituir un riesgo de asfixia. Deséchelas adecuadamente.

Tested and certified by NSF International against NSF/ANSI Standard 42 and 53 in models GXSL55F, GXSL55R and GQSL55F for the reduction of the claims specified on the Performance Data Sheet.

REPLACEMENT

ELEMENT

Testé et homologué par NSF International selon les normes No. 42 et No. 53 NSF/ANSI dans les modèles GXSL55F, GXSL55R et GQSL55F pour la réduction des prétentions indiquées dans la feuille des données de performance.

ÉLEMENT DE

REMPLACEMENT

Probado y certificado por NSF International contra los Estándares NSF/ANSI 42 y 53 en los modelos GXSL55F, GXSL55R y GQSL55F para la reducción de los reclamos especificados en la Hoja de Datos de Desarrollo.

ELEMENTO DE

REEMPLAZO

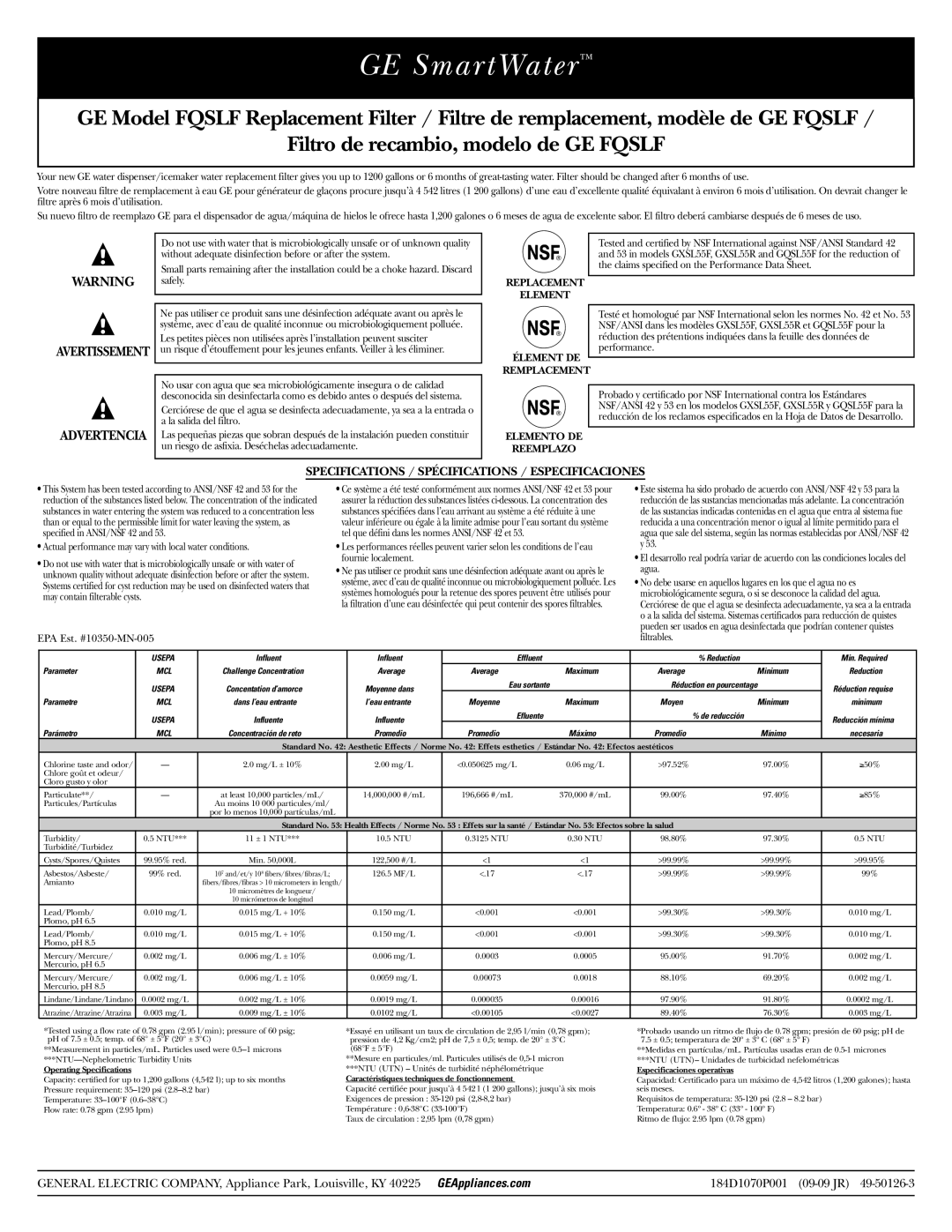

•This System has been tested according to ANSI/NSF 42 and 53 for the reduction of the substances listed below. The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system, as specified in ANSI/NSF 42 and 53.

•Actual performance may vary with local water conditions.

•Do not use with water that is microbiologically unsafe or with water of unknown quality without adequate disinfection before or after the system. Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts.

EPA Est. #10350-MN-005

•Ce système a été testé conformément aux normes ANSI/NSF 42 et 53 pour assurer la réduction des substances listées ci-dessous. La concentration des substances spécifiées dans l’eau arrivant au système a été réduite à une valeur inférieure ou égale à la limite admise pour l’eau sortant du système tel que défini dans les normes ANSI/NSF 42 et 53.

•Les performances réelles peuvent varier selon les conditions de l’eau fournie localement.

•Ne pas utiliser ce produit sans une désinfection adéquate avant ou après le système, avec d’eau de qualité inconnue ou microbiologiquement polluée. Les systèmes homologués pour la retenue des spores peuvent être utilisés pour la filtration d’une eau désinfectée qui peut contenir des spores filtrables.

•Este sistema ha sido probado de acuerdo con ANSI/NSF 42 y 53 para la reducción de las sustancias mencionadas más adelante. La concentración de las sustancias indicadas contenidas en el agua que entra al sistema fue reducida a una concentración menor o igual al límite permitido para el agua que sale del sistema, según las normas establecidas por ANSI/NSF 42 y 53.

•El desarrollo real podría variar de acuerdo con las condiciones locales del agua.

•No debe usarse en aquellos lugares en los que el agua no es microbiológicamente segura, o si se desconoce la calidad del agua. Cerciórese de que el agua se desinfecta adecuadamente, ya sea a la entrada o a la salida del sistema. Sistemas certificados para reducción de quistes pueden ser usados en agua desinfectada que podrían contener quistes filtrables.

*Tested using a flow rate of 0.78 gpm (2.95 l/min); pressure of 60 psig; pH of 7.5 ± 0.5; temp. of 68° ± 5°F (20° ± 3°C)

**Measurement in particles/mL. Particles used were 0.5–1 microns

***NTU—Nephelometric Turbidity Units

Operating Specifications

Capacity: certified for up to 1,200 gallons (4,542 l); up to six months

Pressure requirement: 35–120 psi (2.8–8.2 bar)

Temperature: 33–100°F (0.6–38°C)

Flow rate: 0.78 gpm (2.95 lpm)

*Essayé en utilisant un taux de circulation de 2,95 l/min (0,78 gpm); pression de 4,2 Kg/cm2; pH de 7,5 ± 0,5; temp. de 20° ± 3°C (68°F ± 5°F)

**Mesure en particules/ml. Particules utilisés de 0,5-1 micron

***NTU (UTN) – Unités de turbidité néphélométrique

Caractéristiques techniques de fonctionnement

Capacité certifiée pour jusqu’à 4 542 l (1 200 gallons); jusqu’à six mois Exigences de pression : 35-120 psi (2,8-8,2 bar)

Température : 0,6-38°C (33-100°F)

Taux de circulation : 2,95 lpm (0,78 gpm)

*Probado usando un ritmo de flujo de 0.78 gpm; presión de 60 psig; pH de 7.5 ± 0.5; temperatura de 20º ± 3º C (68º ± 5º F)

**Medidas en partículas/mL. Partículas usadas eran de 0.5-1 micrones

***NTU (UTN)– Unidades de turbicidad nefelométricas

Especificaciones operativas

Capacidad: Certificado para un máximo de 4,542 litros (1,200 galones); hasta seis meses.

Requisitos de temperatura: 35-120 psi (2.8 – 8.2 bar)

Temperatura: 0.6º - 38º C (33º - 100º F)

Ritmo de flujo: 2.95 lpm (0.78 gpm)