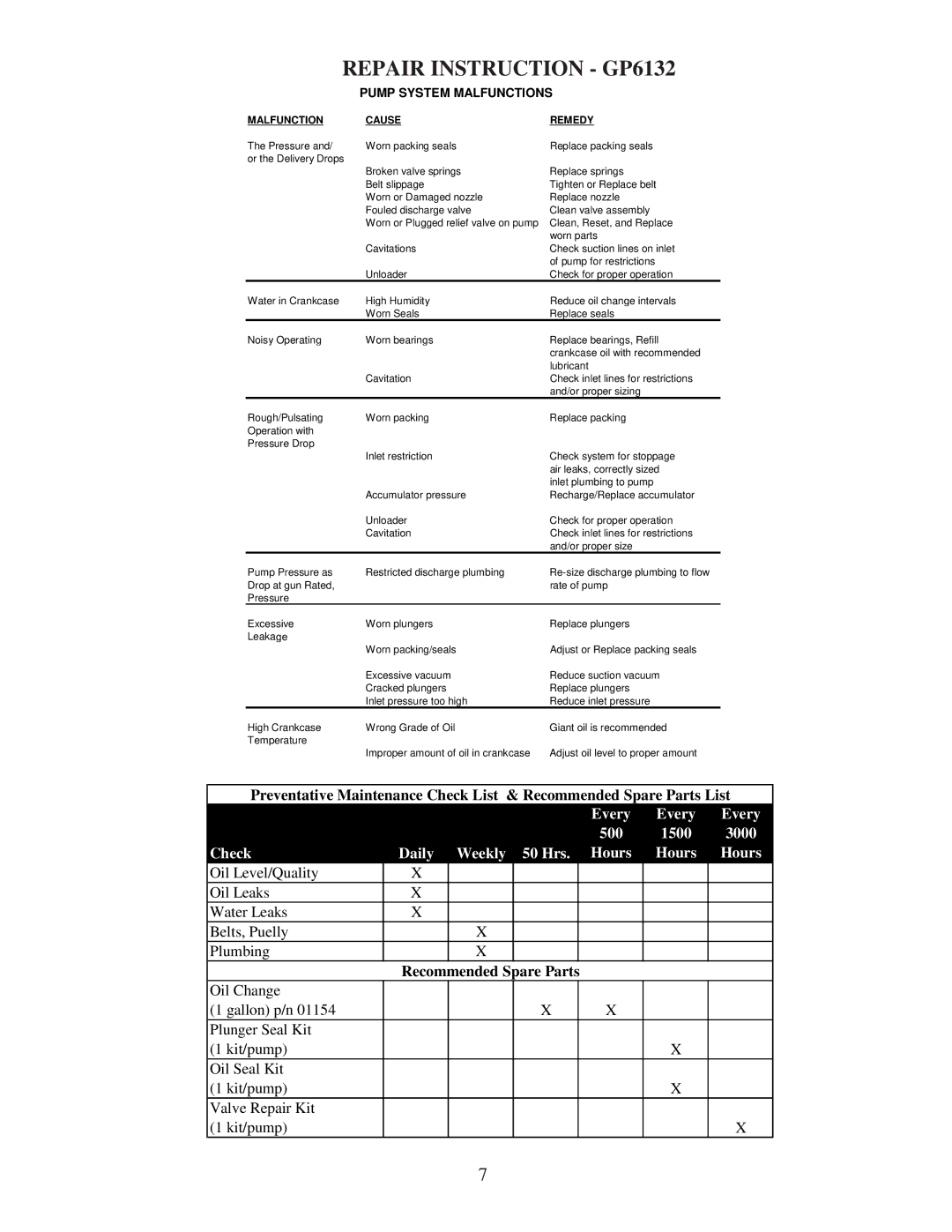

REPAIR INSTRUCTION - GP6132

PUMP SYSTEM MALFUNCTIONS

| MALFUNCTION | CAUSE |

|

| REMEDY |

|

|

|

| |||||

| The Pressure and/ | Worn packing seals |

|

| Replace packing seals |

|

|

|

| |||||

| or the Delivery Drops | Broken valve springs | Replace springs |

|

|

|

| |||||||

|

|

|

|

|

| |||||||||

|

| Belt slippage |

|

| Tighten or Replace belt |

|

| |||||||

|

| Worn or Damaged nozzle | Replace nozzle |

|

|

|

| |||||||

|

| Fouled discharge valve | Clean valve assembly |

|

|

|

| |||||||

|

| Worn or Plugged relief valve on pump | Clean, Reset, and Replace |

|

| |||||||||

|

|

|

|

|

|

| worn parts |

|

|

|

| |||

|

| Cavitations |

|

| Check suction lines on inlet |

|

| |||||||

|

|

|

|

|

|

| of pump for restrictions |

|

|

|

| |||

|

| Unloader |

|

| Check for proper operation |

|

| |||||||

| Water in Crankcase | High Humidity |

|

| Reduce oil change intervals |

|

| |||||||

|

| Worn Seals |

|

| Replace seals |

|

|

|

| |||||

| Noisy Operating | Worn bearings |

|

| Replace bearings, Refill |

|

| |||||||

|

|

|

|

|

|

| crankcase oil with recommended |

|

| |||||

|

|

|

|

|

|

| lubricant |

|

|

|

|

|

| |

|

| Cavitation |

|

| Check inlet lines for restrictions |

|

| |||||||

|

|

|

|

|

|

| and/or proper sizing |

|

|

|

| |||

| Rough/Pulsating | Worn packing |

|

| Replace packing |

|

|

|

| |||||

| Operation with |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Pressure Drop | Inlet restriction |

|

| Check system for stoppage |

|

| |||||||

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

| air leaks, correctly sized |

|

| |||||

|

|

|

|

|

|

| inlet plumbing to pump |

|

|

|

| |||

|

| Accumulator pressure | Recharge/Replace accumulator |

|

| |||||||||

|

| Unloader |

|

| Check for proper operation |

|

| |||||||

|

| Cavitation |

|

| Check inlet lines for restrictions |

|

| |||||||

|

|

|

|

|

|

| and/or proper size |

|

|

|

| |||

| Pump Pressure as | Restricted discharge plumbing |

|

| ||||||||||

| Drop at gun Rated, |

|

|

|

|

| rate of pump |

|

|

|

| |||

| Pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Excessive | Worn plungers |

|

| Replace plungers |

|

|

|

| |||||

| Leakage | Worn packing/seals |

|

| Adjust or Replace packing seals |

|

| |||||||

|

|

|

|

|

| |||||||||

|

| Excessive vacuum |

|

| Reduce suction vacuum |

|

| |||||||

|

| Cracked plungers |

|

| Replace plungers |

|

|

|

| |||||

|

| Inlet pressure too high | Reduce inlet pressure |

|

|

|

| |||||||

| High Crankcase | Wrong Grade of Oil |

|

| Giant oil is recommended |

|

| |||||||

| Temperature | Improper amount of oil in crankcase | Adjust oil level to proper amount |

|

| |||||||||

|

|

|

| |||||||||||

|

| |||||||||||||

| Preventative Maintenance Check List & Recommended Spare Parts List | |||||||||||||

|

|

|

|

|

|

|

|

| Every |

| Every |

|

| Every |

|

|

|

|

|

|

|

|

| 500 |

| 1500 |

| 3000 | |

Check |

| Daily |

| Weekly | 50 Hrs. |

| Hours |

| Hours |

| Hours | |||

Oil Level/Quality |

| X |

|

|

|

|

|

|

|

|

|

|

| |

Oil Leaks |

| X |

|

|

|

|

|

|

|

|

|

|

| |

Water Leaks |

| X |

|

|

|

|

|

|

|

|

|

|

| |

Belts, Puelly |

|

|

| X |

|

|

|

|

|

|

|

|

| |

Plumbing |

|

|

| X |

|

|

|

|

|

|

|

|

| |

|

|

| Recommended Spare Parts |

|

|

|

|

|

| |||||

Oil Change |

|

|

|

|

|

|

|

|

|

|

|

|

| |

(1 gallon) p/n 01154 |

|

|

|

|

| X |

| X |

|

|

|

|

| |

Plunger Seal Kit |

|

|

|

|

|

|

|

|

|

|

|

|

| |

(1 kit/pump) |

|

|

|

|

|

|

|

|

| X |

|

|

| |

Oil Seal Kit |

|

|

|

|

|

|

|

|

|

|

|

|

| |

(1 kit/pump) |

|

|

|

|

|

|

|

|

| X |

|

|

| |

Valve Repair Kit |

|

|

|

|

|

|

|

|

|

|

|

|

| |

(1 kit/pump) |

|

|

|

|

|

|

|

|

|

|

|

| X | |

7