GP7122 REPAIR INSTRUCTIONS

TO ASSEMBLE VALVE CASING

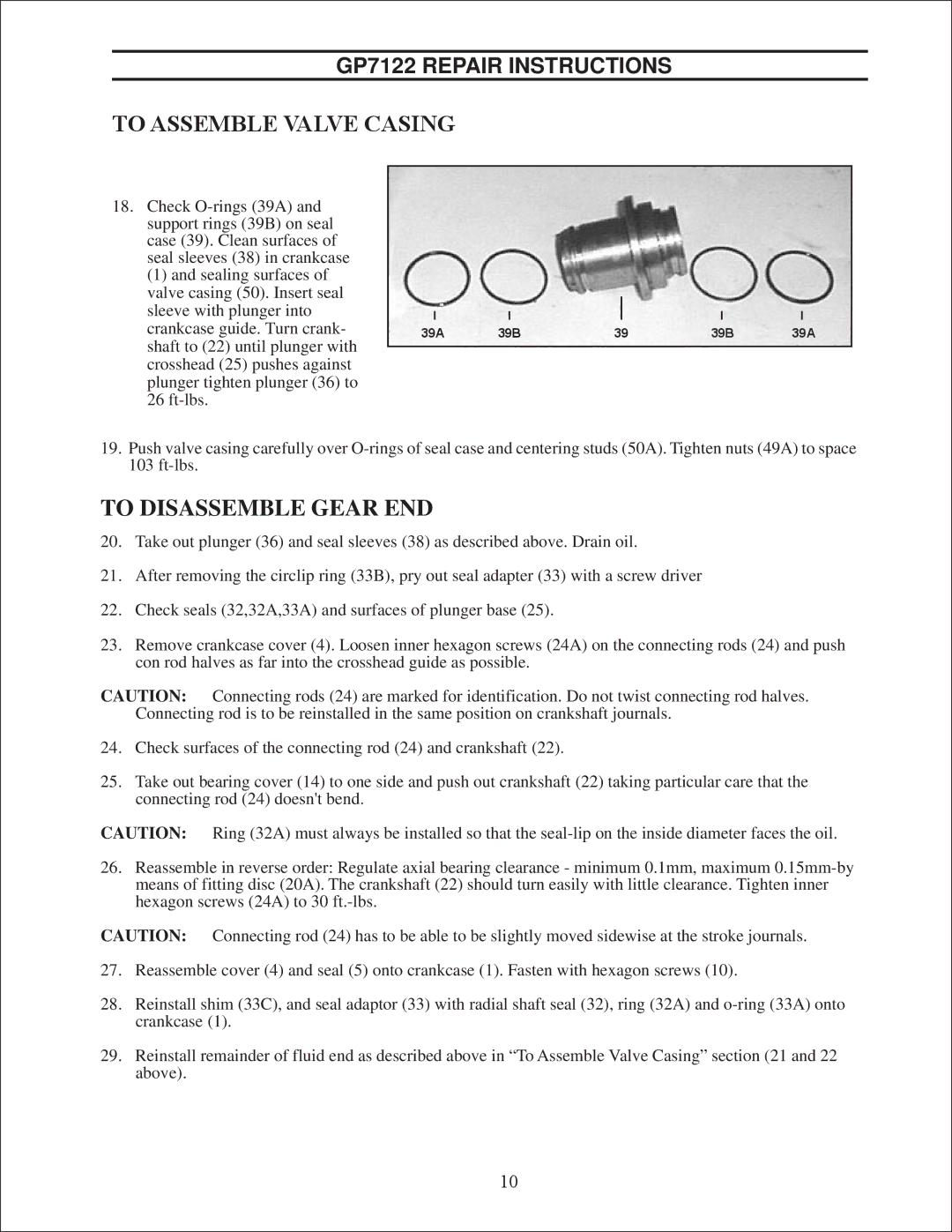

18.Check

(1) and sealing surfaces of valve casing (50). Insert seal sleeve with plunger into crankcase guide. Turn crank- shaft to (22) until plunger with crosshead (25) pushes against plunger tighten plunger (36) to 26

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

39A | 39B | 39 | 39B | 39A | |||||

|

|

|

|

|

|

|

|

|

|

19.Push valve casing carefully over

TO DISASSEMBLE GEAR END

20.Take out plunger (36) and seal sleeves (38) as described above. Drain oil.

21.After removing the circlip ring (33B), pry out seal adapter (33) with a screw driver

22.Check seals (32,32A,33A) and surfaces of plunger base (25).

23.Remove crankcase cover (4). Loosen inner hexagon screws (24A) on the connecting rods (24) and push con rod halves as far into the crosshead guide as possible.

CAUTION: Connecting rods (24) are marked for identification. Do not twist connecting rod halves. Connecting rod is to be reinstalled in the same position on crankshaft journals.

24.Check surfaces of the connecting rod (24) and crankshaft (22).

25.Take out bearing cover (14) to one side and push out crankshaft (22) taking particular care that the connecting rod (24) doesn't bend.

CAUTION: Ring (32A) must always be installed so that the

26.Reassemble in reverse order: Regulate axial bearing clearance - minimum 0.1mm, maximum

CAUTION: Connecting rod (24) has to be able to be slightly moved sidewise at the stroke journals.

27.Reassemble cover (4) and seal (5) onto crankcase (1). Fasten with hexagon screws (10).

28.Reinstall shim (33C), and seal adaptor (33) with radial shaft seal (32), ring (32A) and

29.Reinstall remainder of fluid end as described above in “To Assemble Valve Casing” section (21 and 22 above).

10