SP100W specifications

The Giant SP100W is a standout model in the world of e-mountain bikes, designed for enthusiasts who crave power, performance, and versatility on rugged terrains. This bike seamlessly integrates cutting-edge battery technology and robust construction, ensuring a remarkable riding experience.At the heart of the SP100W lies its powerful 250W motor, which provides an exceptional boost, making steep climbs and challenging trails much more manageable. The motor's efficient power delivery is accompanied by a 500Wh lithium-ion battery, offering extended range and performance. Riders can expect up to 75 miles of assistance, depending on riding conditions and terrain, thanks to the bike's smart energy management system that optimizes battery usage.

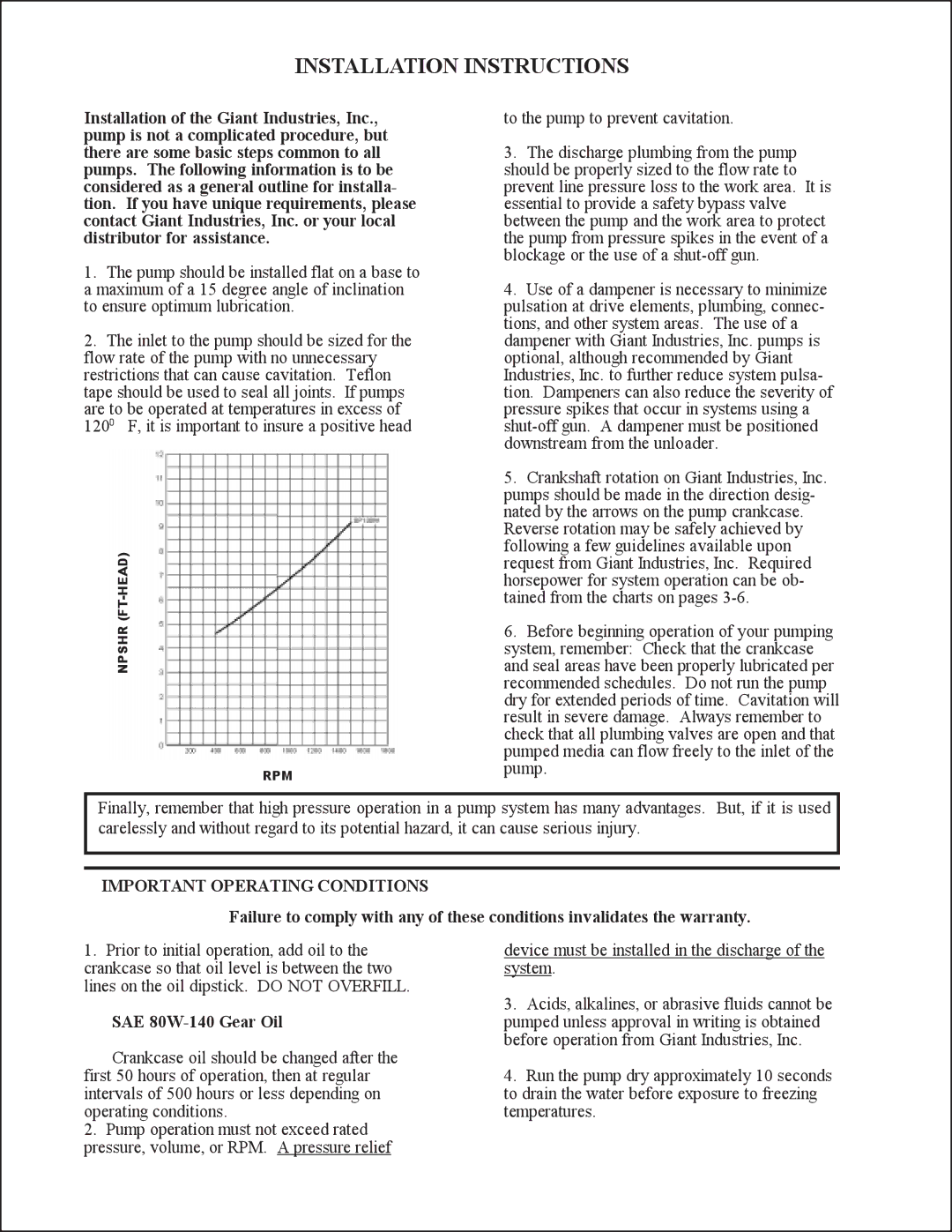

One of the most notable features of the Giant SP100W is its advanced suspension system. The front fork is equipped with 120mm of travel, ensuring smooth navigation over rough patches and absorbing shocks effectively. This, combined with the bike's lightweight aluminum frame, allows for a stable ride, whether descending steep inclines or traversing technical trails.

The SP100W also boasts a 1x drivetrain, simplifying gear shifting and enhancing reliability. With a wide range of gears, it enables riders to tackle varying gradients with ease. Furthermore, its hydraulic disc brakes provide excellent stopping power in all conditions, ensuring safety on steep descents and uneven surfaces.

Design-wise, the Giant SP100W features an ergonomic geometry that promotes comfortable riding positions, suitable for long excursions. The integrated lighting system ensures visibility during low-light conditions, making it an all-around bike for day and night adventures.

Another key characteristic of the SP100W is its connectivity features. With built-in Bluetooth technology, riders can connect their smartphones for real-time tracking, navigation, and performance metrics. The bike's intuitive display provides crucial information, including speed, battery status, and distance traveled, enabling users to monitor their performance effectively.

In summary, the Giant SP100W is designed for riders who demand versatility and durability in their e-mountain biking experience. With its powerful motor and intelligent design features, it sets a new standard for reliability and enjoyment on the trails, making it an exceptional choice for both experienced and novice mountain bikers alike. Whether navigating rocky terrains or enjoying leisurely paths, the SP100W stands ready to deliver adventure.