3.Adjust the table angle by rotating the table angle adjustment knob (17). Rotate the knob in an

4.Tighten the table angle locking

knob (16) to secure the table in position.

Note. When greater precision is required, make a practice cut first on a scrap piece of similar wood and then adjust the table as necessary for your requirements.

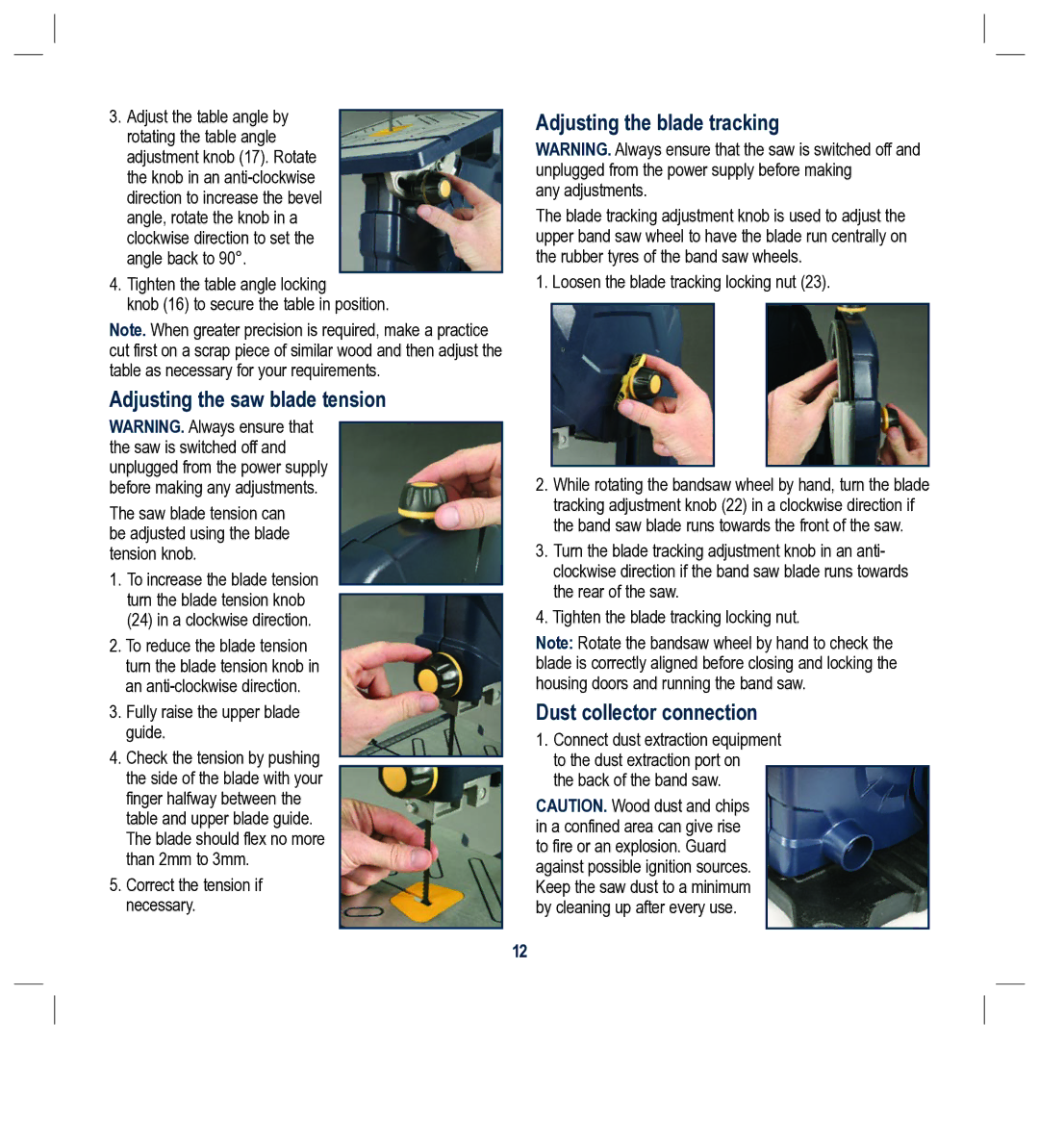

Adjusting the saw blade tension

WARNING. Always ensure that the saw is switched off and unplugged from the power supply before making any adjustments.

The saw blade tension can be adjusted using the blade tension knob.

1.To increase the blade tension turn the blade tension knob (24) in a clockwise direction.

2.To reduce the blade tension turn the blade tension knob in an

3.Fully raise the upper blade guide.

4.Check the tension by pushing the side of the blade with your finger halfway between the table and upper blade guide. The blade should flex no more than 2mm to 3mm.

5.Correct the tension if necessary.

Adjusting the blade tracking

WARNING. Always ensure that the saw is switched off and unplugged from the power supply before making

any adjustments.

The blade tracking adjustment knob is used to adjust the upper band saw wheel to have the blade run centrally on the rubber tyres of the band saw wheels.

1. Loosen the blade tracking locking nut (23).

2.While rotating the bandsaw wheel by hand, turn the blade tracking adjustment knob (22) in a clockwise direction if the band saw blade runs towards the front of the saw.

3.Turn the blade tracking adjustment knob in an anti- clockwise direction if the band saw blade runs towards the rear of the saw.

4.Tighten the blade tracking locking nut.

Note: Rotate the bandsaw wheel by hand to check the blade is correctly aligned before closing and locking the housing doors and running the band saw.

Dust collector connection

1.Connect dust extraction equipment to the dust extraction port on

the back of the band saw.

CAUTION. Wood dust and chips in a confined area can give rise to fire or an explosion. Guard against possible ignition sources. Keep the saw dust to a minimum by cleaning up after every use.

12