2. Remove the collet (5) and

replace with the desiredF collet (fig. F). The size of

the collet will depend on the shaft diameter of the accessory to be used.

3.Press the spindle lock button (2) and hand tighten the collet nut (3) by turning it in a clockwise direction.

Changing accessories

WARNING. If the accessory has not been inserted as far as possible there may be too much shaft exposed which could cause the bit to damage and/or bend.

IMPORTANT. Ensure the machine is switched off and the plug is removed from the power before you commence accessory changeover.

Note. Loosen and tighten the collet nut (3) with your hands. Never tighten the collet nut (3) with the use of pliers or any other clamping device as the collet nut (3) may strip.

Always ensure bits are tight before commencing any work with your tool.

1.Turn the collet nut (3) in an

Note. If the shaft of the rotary tool is too large to fit into the collet (5) or fits too loosely, it is necessary to change the collet. Refer to ‘Changing the collet’ of this manual

for instructions.

2.Whilst depressing the spindle lock button (2), hand tighten the collet nut (3) by turning it clockwise until tight.

Note. If the rotary tool piece is not spinning, yet the collet nut (3) is spinning, the collet nut (3) may need to be tightened further.

Locating a cutting /sanding disc

1. | Locate an appropriate disc mandrel (holder) into |

| |

| the collet (5). |

| |

2. | Remove the screw from |

|

|

| H | ||

| the end of the disc mandrel | ||

|

| ||

| with the |

| |

| turning in an |

| |

| direction (fig. H). |

| |

3.Place a cutting/sanding disc onto the screw of the disc mandrel (placing one of the rubber washers provided with the disc mandrel on either side of the for protection).

4.Place the screw, with the disc onto the disc shaft and tighten with the

Locating a sanding drum

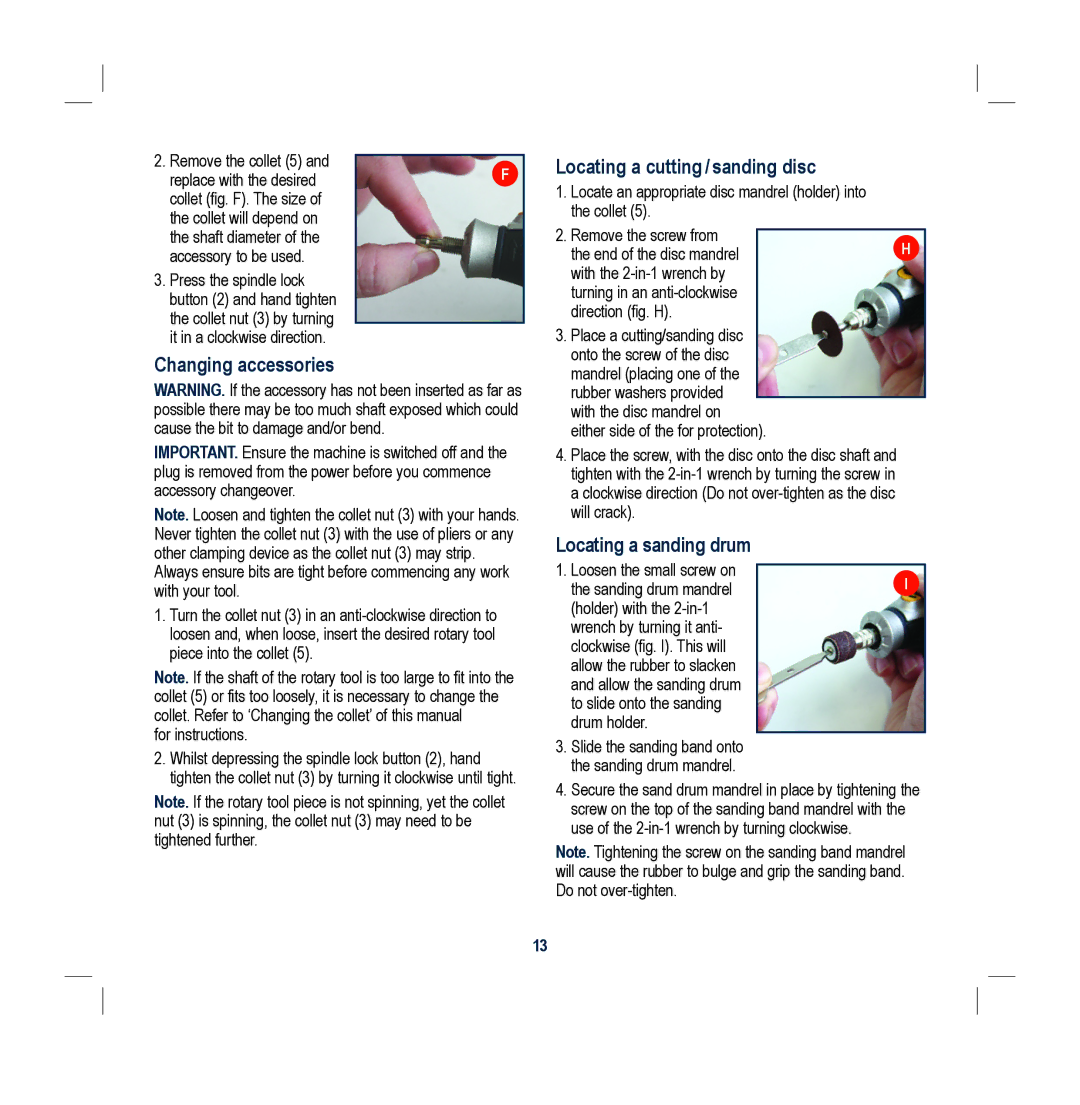

1. Loosen the small screw on

the sanding drum mandrelI (holder) with the

wrench by turning it anti- clockwise (fig. I). This will allow the rubber to slacken and allow the sanding drum to slide onto the sanding drum holder.

3.Slide the sanding band onto the sanding drum mandrel.

4.Secure the sand drum mandrel in place by tightening the screw on the top of the sanding band mandrel with the use of the

Note. Tightening the screw on the sanding band mandrel will cause the rubber to bulge and grip the sanding band. Do not

13