NOTE: Edging of heavily overgrown edges and damp soils can create greater

Maintenance

Changing the Blade

WARNING: Before performing any maintenance or tool adjustments ensure the power supply cable has been totally disconnected from the mains power.

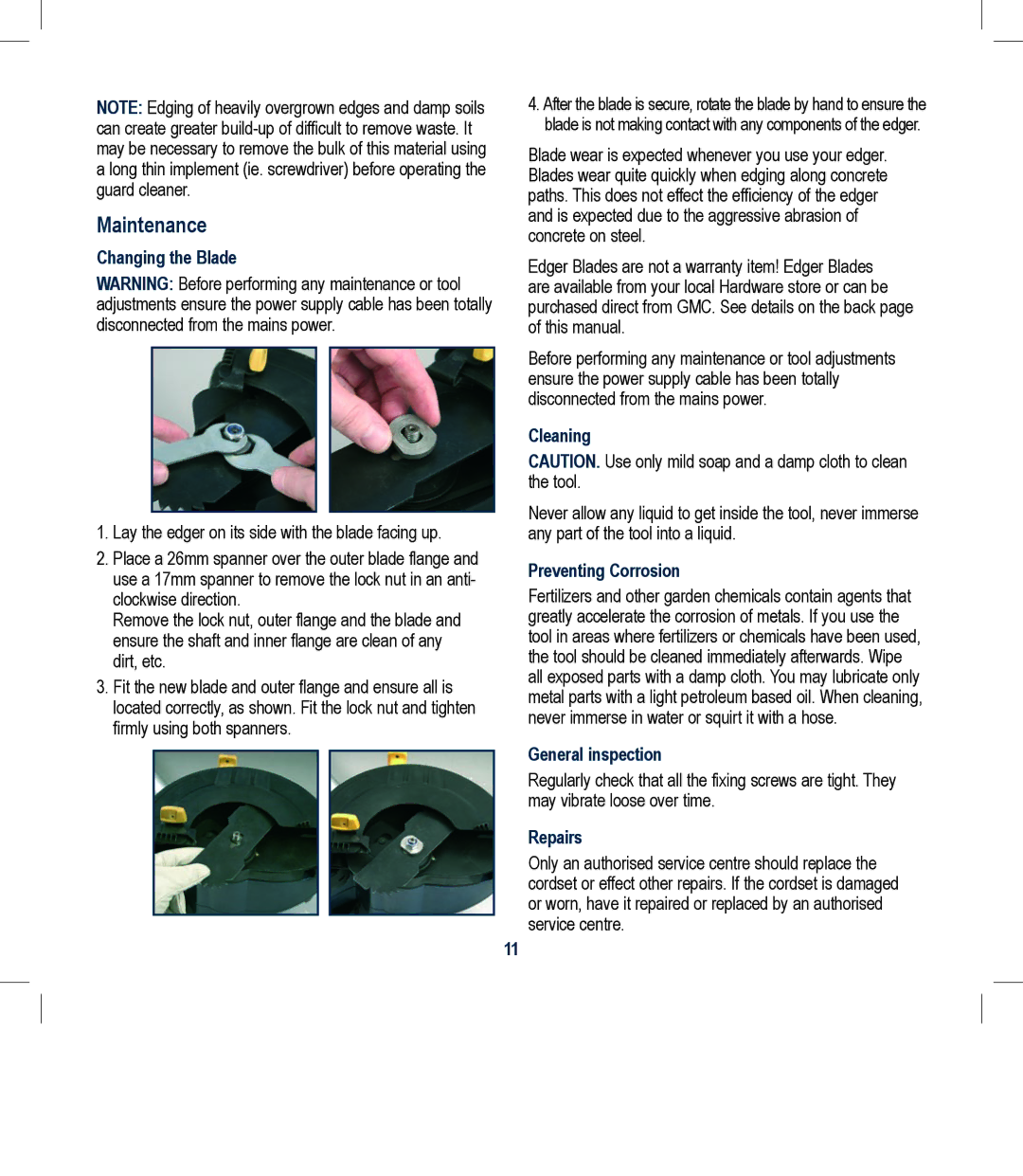

1.Lay the edger on its side with the blade facing up.

2.Place a 26mm spanner over the outer blade flange and use a 17mm spanner to remove the lock nut in an anti- clockwise direction.

Remove the lock nut, outer flange and the blade and ensure the shaft and inner flange are clean of any dirt, etc.

3.Fit the new blade and outer flange and ensure all is located correctly, as shown. Fit the lock nut and tighten firmly using both spanners.

4.After the blade is secure, rotate the blade by hand to ensure the blade is not making contact with any components of the edger.

Blade wear is expected whenever you use your edger. Blades wear quite quickly when edging along concrete paths. This does not effect the efficiency of the edger and is expected due to the aggressive abrasion of concrete on steel.

Edger Blades are not a warranty item! Edger Blades are available from your local Hardware store or can be purchased direct from GMC. See details on the back page of this manual.

Before performing any maintenance or tool adjustments ensure the power supply cable has been totally disconnected from the mains power.

Cleaning

CAUTION. Use only mild soap and a damp cloth to clean the tool.

Never allow any liquid to get inside the tool, never immerse any part of the tool into a liquid.

Preventing Corrosion

Fertilizers and other garden chemicals contain agents that greatly accelerate the corrosion of metals. If you use the tool in areas where fertilizers or chemicals have been used, the tool should be cleaned immediately afterwards. Wipe all exposed parts with a damp cloth. You may lubricate only metal parts with a light petroleum based oil. When cleaning, never immerse in water or squirt it with a hose.

General inspection

Regularly check that all the fixing screws are tight. They may vibrate loose over time.

Repairs

Only an authorised service centre should replace the cordset or effect other repairs. If the cordset is damaged or worn, have it repaired or replaced by an authorised service centre.

11