Maintenance

WARNING. Always ensure that the tool is switched off and the plug is removed from the power point before making any adjustments or maintenance procedures.

Cleaning

1.Keep the tool’s air vents unclogged and clean at all times.

2.Remove dust and dirt regularly. Cleaning is best done with a rag.

3.

4.If the body of the saw needs cleaning, wipe it with a soft damp cloth. A mild detergent can be used but nothing like alcohol, petrol or other cleaning agent.

5.Never use caustic agents to clean plastic parts.

CAUTION. Do not use cleaning agents to clean the plastic parts of the tool. A mild detergent on a damp cloth is recommended. Water must never come into contact

with the tool.

General inspection

Regularly check that all the fixing screws are tight. They may vibrate loose over time.

Power cord maintenance

If the supply cord needs replacing, the task must be carried out by the manufacturer, the manufacturer’s agent, or a qualified electrical service repairer to avoid a safety hazard.

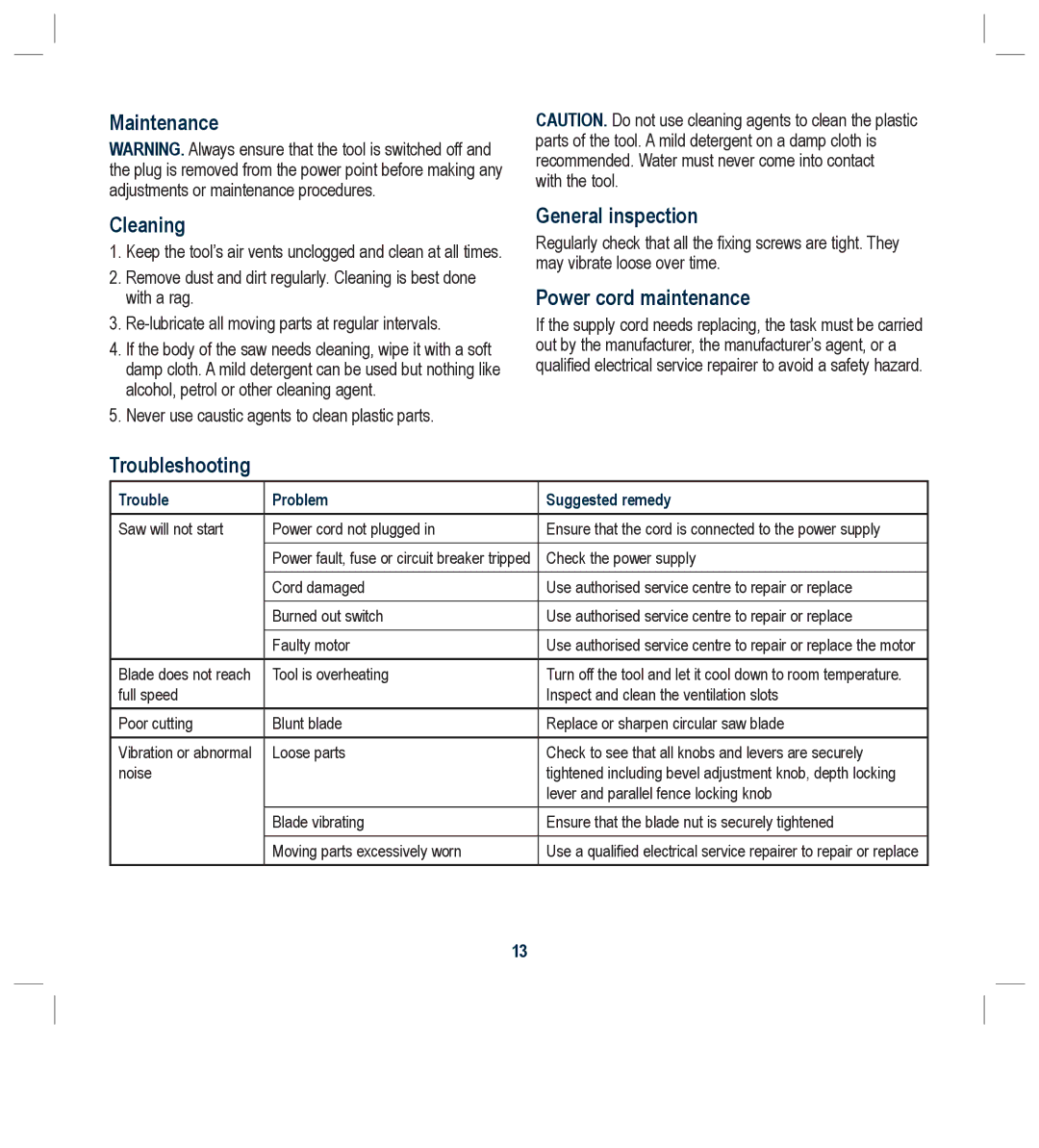

Troubleshooting

Trouble | Problem | Suggested remedy |

|

|

|

Saw will not start | Power cord not plugged in | Ensure that the cord is connected to the power supply |

|

|

|

| Power fault, fuse or circuit breaker tripped | Check the power supply |

|

|

|

| Cord damaged | Use authorised service centre to repair or replace |

|

|

|

| Burned out switch | Use authorised service centre to repair or replace |

|

|

|

| Faulty motor | Use authorised service centre to repair or replace the motor |

|

|

|

Blade does not reach | Tool is overheating | Turn off the tool and let it cool down to room temperature. |

full speed |

| Inspect and clean the ventilation slots |

|

|

|

Poor cutting | Blunt blade | Replace or sharpen circular saw blade |

|

|

|

Vibration or abnormal | Loose parts | Check to see that all knobs and levers are securely |

noise |

| tightened including bevel adjustment knob, depth locking |

|

| lever and parallel fence locking knob |

|

|

|

| Blade vibrating | Ensure that the blade nut is securely tightened |

|

|

|

| Moving parts excessively worn | Use a qualified electrical service repairer to repair or replace |

|

|

|

13