Adjusting the laser line

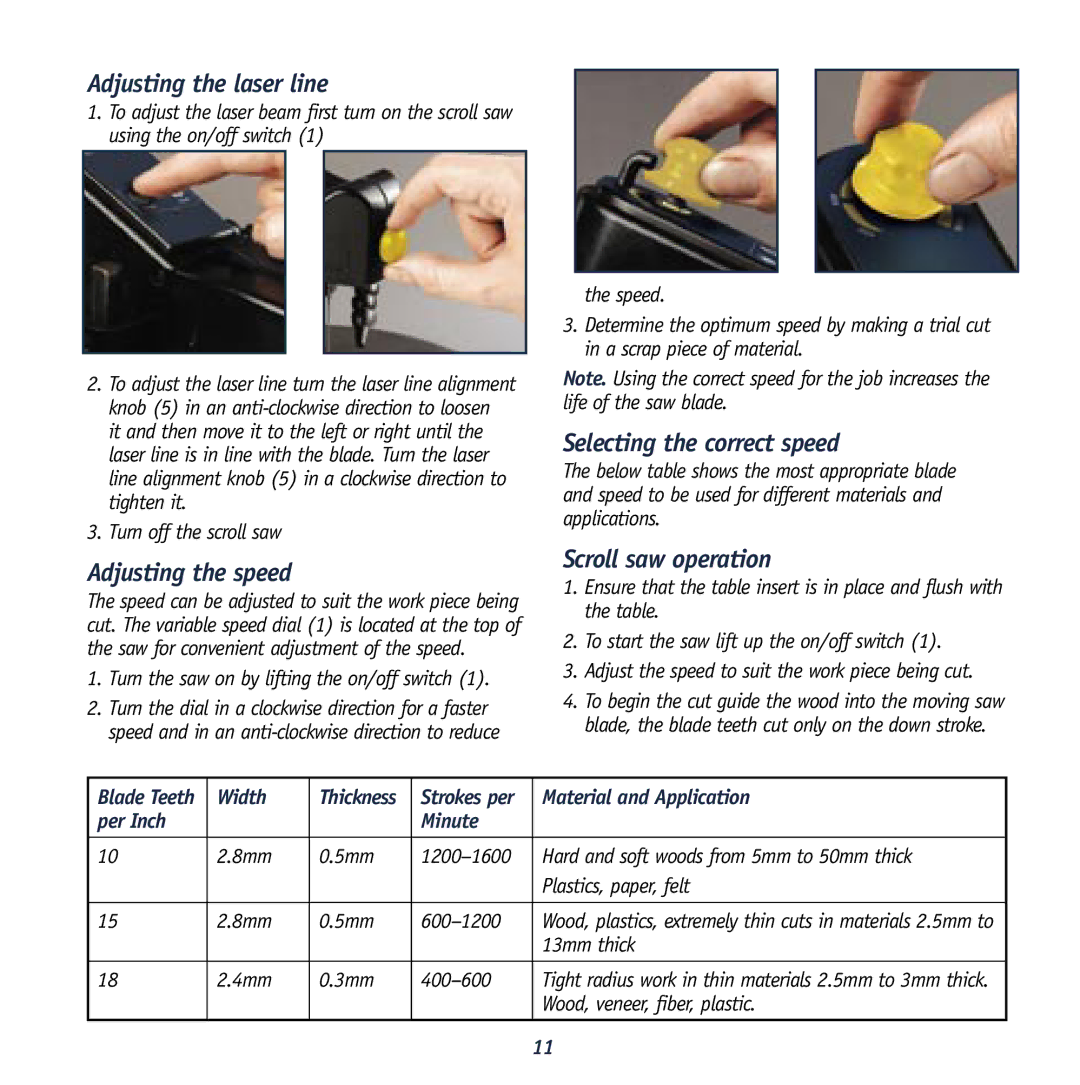

1.To adjust the laser beam first turn on the scroll saw using the on/off switch (1)

2.To adjust the laser line turn the laser line alignment knob (5) in an

3.Turn off the scroll saw

Adjusting the speed

The speed can be adjusted to suit the work piece being cut. The variable speed dial (1) is located at the top of the saw for convenient adjustment of the speed.

1.Turn the saw on by lifting the on/off switch (1).

2.Turn the dial in a clockwise direction for a faster speed and in an

the speed.

3.Determine the optimum speed by making a trial cut in a scrap piece of material.

Note. Using the correct speed for the job increases the life of the saw blade.

Selecting the correct speed

The below table shows the most appropriate blade and speed to be used for different materials and applications.

Scroll saw operation

1.Ensure that the table insert is in place and flush with the table.

2.To start the saw lift up the on/off switch (1).

3.Adjust the speed to suit the work piece being cut.

4.To begin the cut guide the wood into the moving saw blade, the blade teeth cut only on the down stroke.

Blade Teeth | Width | Thickness | Strokes per | Material and Application |

per Inch |

|

| Minute |

|

|

|

|

|

|

10 | 2.8mm | 0.5mm | Hard and soft woods from 5mm to 50mm thick | |

|

|

|

| Plastics, paper, felt |

|

|

|

|

|

15 | 2.8mm | 0.5mm | Wood, plastics, extremely thin cuts in materials 2.5mm to | |

|

|

|

| 13mm thick |

|

|

|

|

|

18 | 2.4mm | 0.3mm | Tight radius work in thin materials 2.5mm to 3mm thick. | |

|

|

|

| Wood, veneer, fiber, plastic. |

|

|

|

|

|

11