Maintenance

Warning. Always ensure that the tool is switched off and the plug is removed from the power point before making and adjustments or maintenance procedures.

An occasional coat of paste wax on the work table will allow the wood being cut to glide smoothly across the work surface.

Oiling the arm bearings

The saws arm bearings should be lubricated after every 50 hours of use. Ensure plug is removed from the mains power supply.

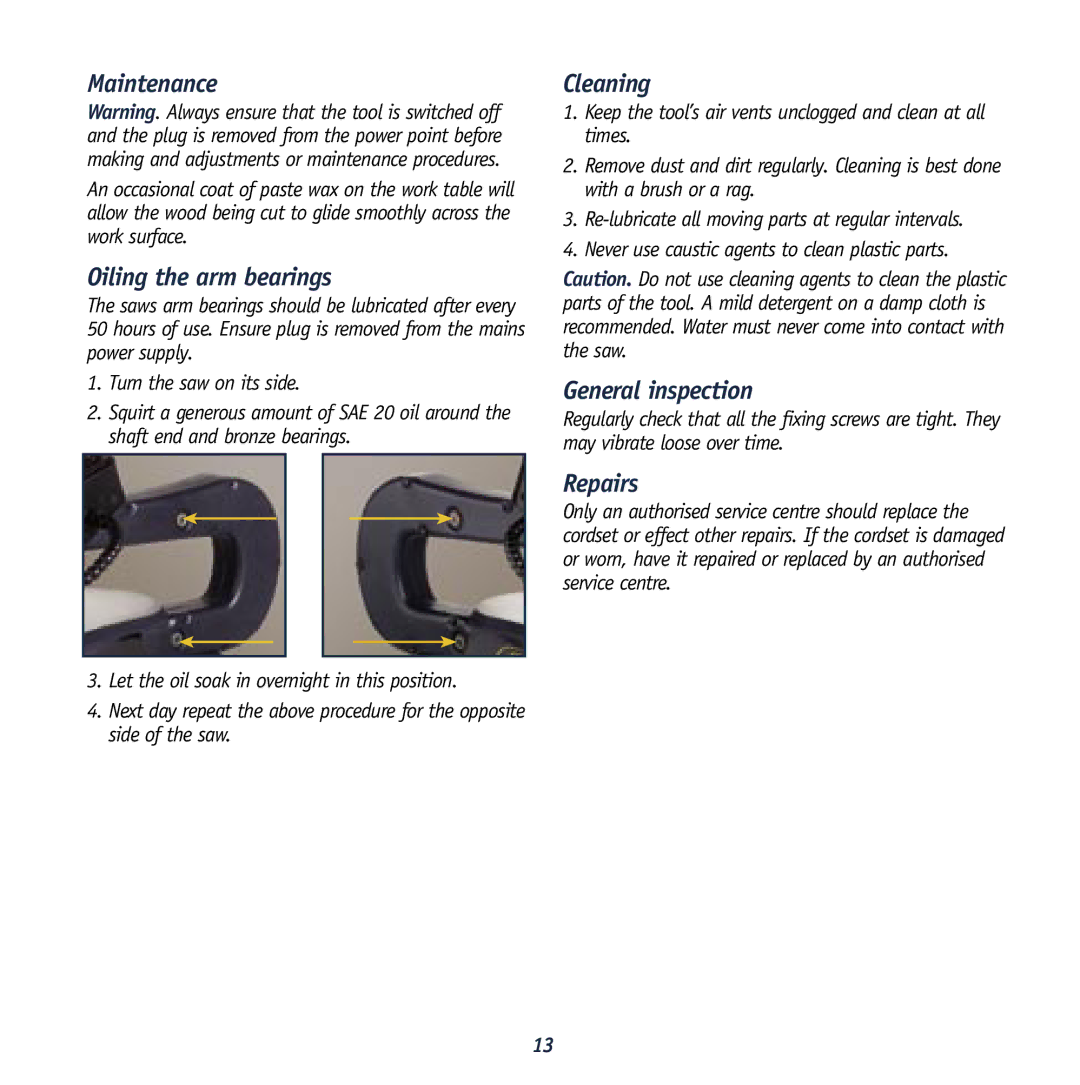

1.Turn the saw on its side.

2.Squirt a generous amount of SAE 20 oil around the shaft end and bronze bearings.

3.Let the oil soak in overnight in this position.

4.Next day repeat the above procedure for the opposite side of the saw.

Cleaning

1.Keep the tool’s air vents unclogged and clean at all times.

2.Remove dust and dirt regularly. Cleaning is best done with a brush or a rag.

3.

4.Never use caustic agents to clean plastic parts.

Caution. Do not use cleaning agents to clean the plastic parts of the tool. A mild detergent on a damp cloth is recommended. Water must never come into contact with the saw.

General inspection

Regularly check that all the fixing screws are tight. They may vibrate loose over time.

Repairs

Only an authorised service centre should replace the cordset or effect other repairs. If the cordset is damaged or worn, have it repaired or replaced by an authorised service centre.

13