To increase the regulated air pressure rotate the pressure regulating knob clockwise. To decrease the regulated air pressure rotate the regulating knob

When setting the the regulated outlet pressure always start with the pressure being low, working your way up to the desired regulated pressure.

Note. Ifyou do not allow the air to discharge while you are setting the regulator, the pressure as indicated on the regulated outlet gauge will be incorrect. This gauge ONLY indicates the correct pressure while air is being discharged from the outlet and through the air tool/accessory to be used.

Stopping the air |

| ||

E | |||

compressor | |||

| |||

On completion of using the |

| ||

compressor, or when you are |

| ||

leaving the compressor unattended, |

| ||

turn off the compressor in the |

| ||

following way: |

| ||

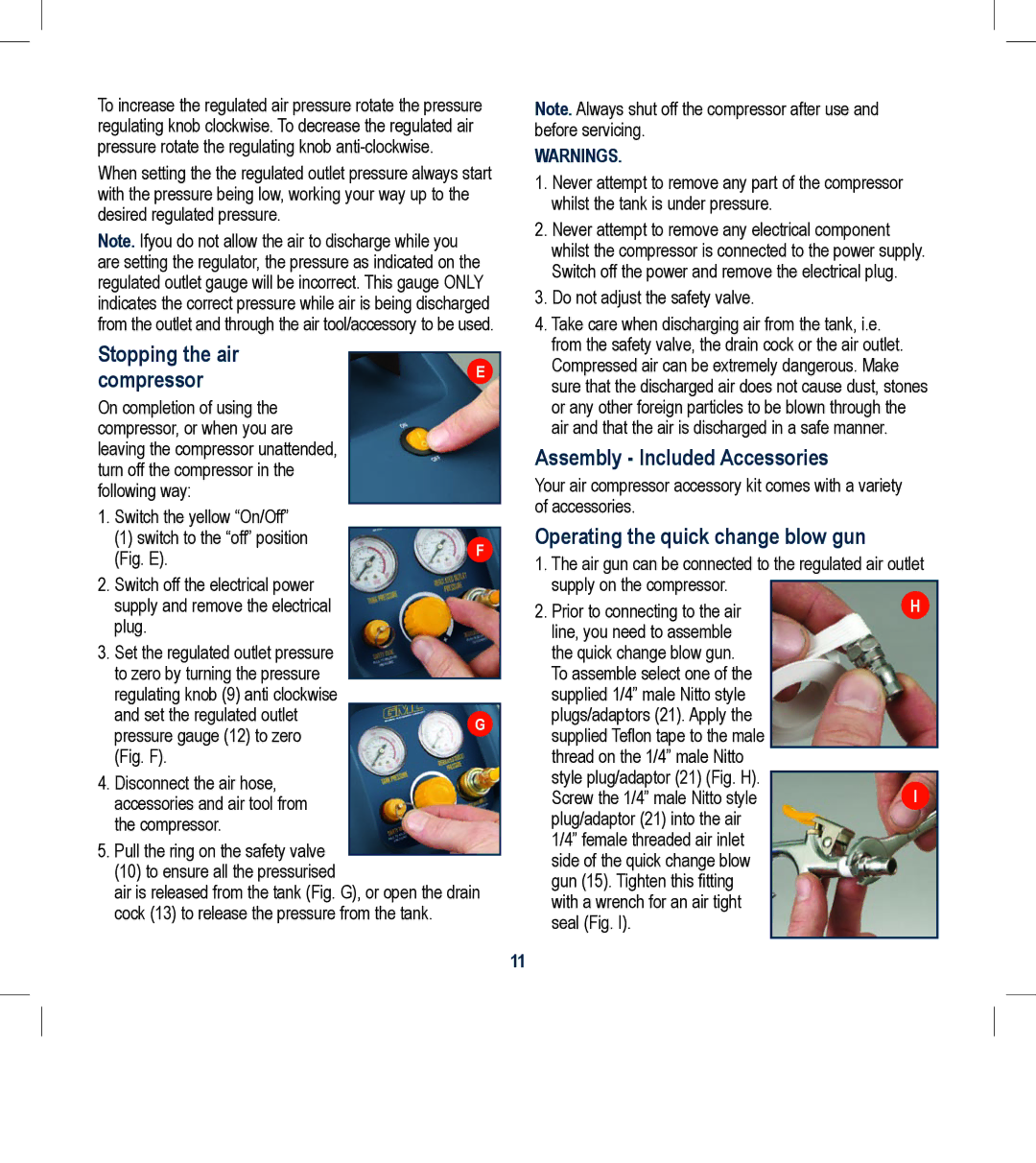

1. Switch the yellow “On/Off” |

| ||

(1) switch to the “off” position |

| F | |

(Fig. E). | |||

| |||

2.Switch off the electrical power supply and remove the electrical plug.

3.Set the regulated outlet pressure to zero by turning the pressure regulating knob (9) anti clockwise

and set the regulated outlet | G | |

pressure gauge (12) to zero | ||

| ||

(Fig. F). |

|

4.Disconnect the air hose, accessories and air tool from the compressor.

5.Pull the ring on the safety valve (10) to ensure all the pressurised

air is released from the tank (Fig. G), or open the drain cock (13) to release the pressure from the tank.

Note. Always shut off the compressor after use and before servicing.

WARNINGS.

1.Never attempt to remove any part of the compressor whilst the tank is under pressure.

2.Never attempt to remove any electrical component whilst the compressor is connected to the power supply. Switch off the power and remove the electrical plug.

3.Do not adjust the safety valve.

4.Take care when discharging air from the tank, i.e. from the safety valve, the drain cock or the air outlet. Compressed air can be extremely dangerous. Make sure that the discharged air does not cause dust, stones or any other foreign particles to be blown through the air and that the air is discharged in a safe manner.

Assembly - Included Accessories

Your air compressor accessory kit comes with a variety of accessories.

Operating the quick change blow gun

1.The air gun can be connected to the regulated air outlet supply on the compressor.

2. Prior to connecting to the air | H | |

line, you need to assemble |

| |

the quick change blow gun. |

| |

To assemble select one of the |

| |

supplied 1/4” male Nitto style |

| |

plugs/adaptors (21). Apply the |

| |

supplied Teflon tape to the male |

| |

thread on the 1/4” male Nitto |

| |

style plug/adaptor (21) (Fig. H). |

| |

I | ||

Screw the 1/4” male Nitto style | ||

plug/adaptor (21) into the air |

| |

1/4” female threaded air inlet |

| |

side of the quick change blow |

| |

gun (15). Tighten this fitting |

| |

with a wrench for an air tight |

| |

seal (Fig. I). |

| |

|

|

11