General cutting

1.Hold the saw firmly in front and clearly away from you.

2.Make sure that the blade is clear of any obstruction and that the power cord or any extension cord is out of the path of the blade.

3.Ensure that the material to be cut is held firmly. Small work pieces should be held in a vice or clamped to the workbench.

4.Mark out the cutting line.

5.Press the

6.Wait until the saw has reached maximum speed.

7.Place the shoe on the work piece and begin sawing.

NOTE. Use only enough pressure to keep the saw cutting. Do not force the cutting; allow the blade and the saw to do the work.

WARNING. Use of excessive pressure that causes bending or twisting of the blade may cause the blade to break.

Plunge cutting

1.Mark the line of the cut.

2.Choose a point inside the area to be cut out and place the tip of the blade over that point.

3.Rest the front edge of the shoe on the work piece and hold the saw firmly in position.

4.Press the

WARNING. Make sure that the blade does not touch the work piece until the blade has reached maximum speed since this could cause loss of control and serious injury.

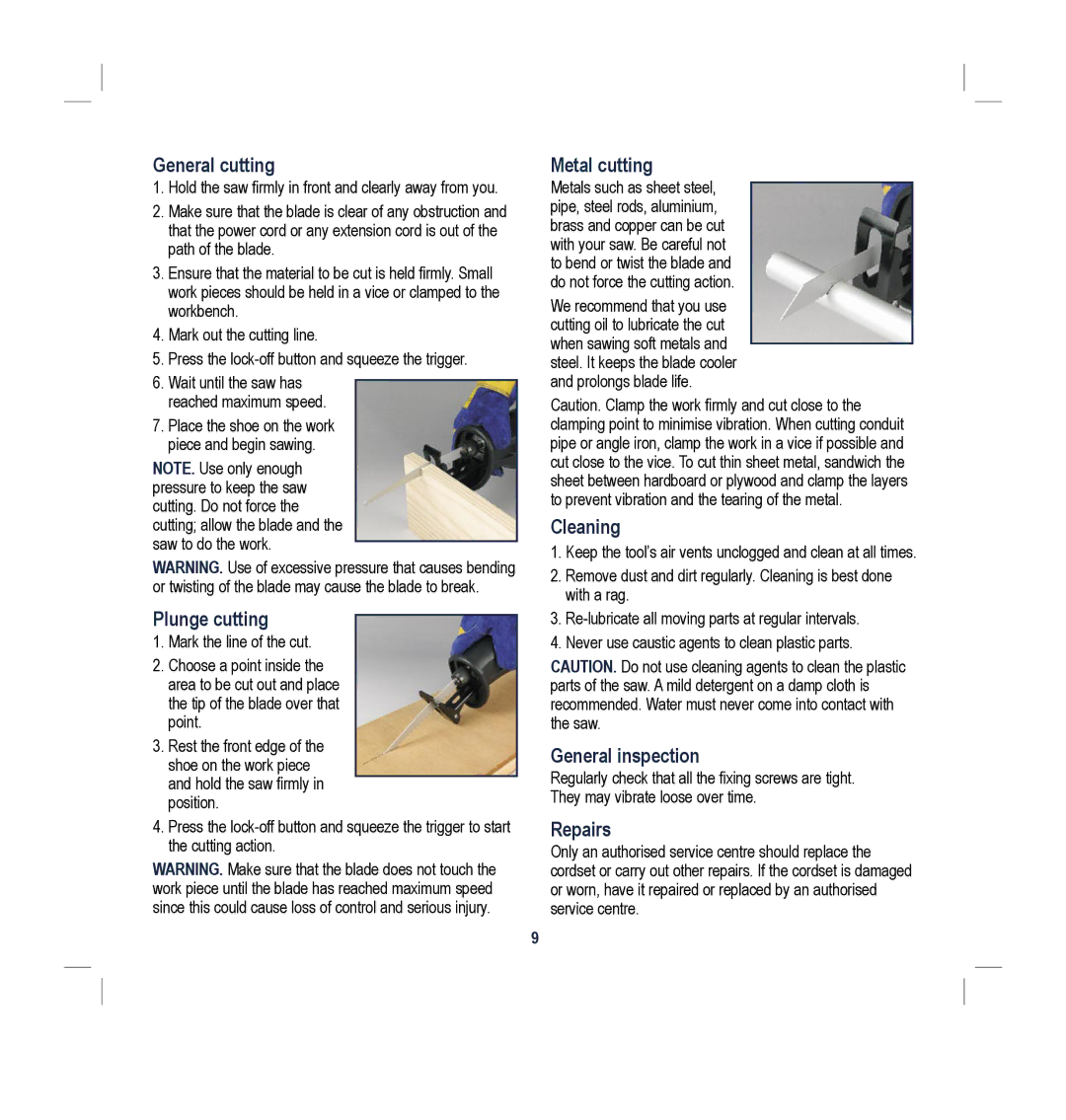

Metal cutting

Metals such as sheet steel, pipe, steel rods, aluminium, brass and copper can be cut with your saw. Be careful not to bend or twist the blade and do not force the cutting action.

We recommend that you use cutting oil to lubricate the cut when sawing soft metals and steel. It keeps the blade cooler and prolongs blade life.

Caution. Clamp the work firmly and cut close to the clamping point to minimise vibration. When cutting conduit pipe or angle iron, clamp the work in a vice if possible and cut close to the vice. To cut thin sheet metal, sandwich the sheet between hardboard or plywood and clamp the layers to prevent vibration and the tearing of the metal.

Cleaning

1.Keep the tool’s air vents unclogged and clean at all times.

2.Remove dust and dirt regularly. Cleaning is best done with a rag.

3.

4.Never use caustic agents to clean plastic parts.

CAUTION. Do not use cleaning agents to clean the plastic parts of the saw. A mild detergent on a damp cloth is recommended. Water must never come into contact with the saw.

General inspection

Regularly check that all the fixing screws are tight. They may vibrate loose over time.

Repairs

Only an authorised service centre should replace the cordset or carry out other repairs. If the cordset is damaged or worn, have it repaired or replaced by an authorised service centre.

9