it to just make contact with the depth turret stop (8). Take note of the measurement on the depth label.

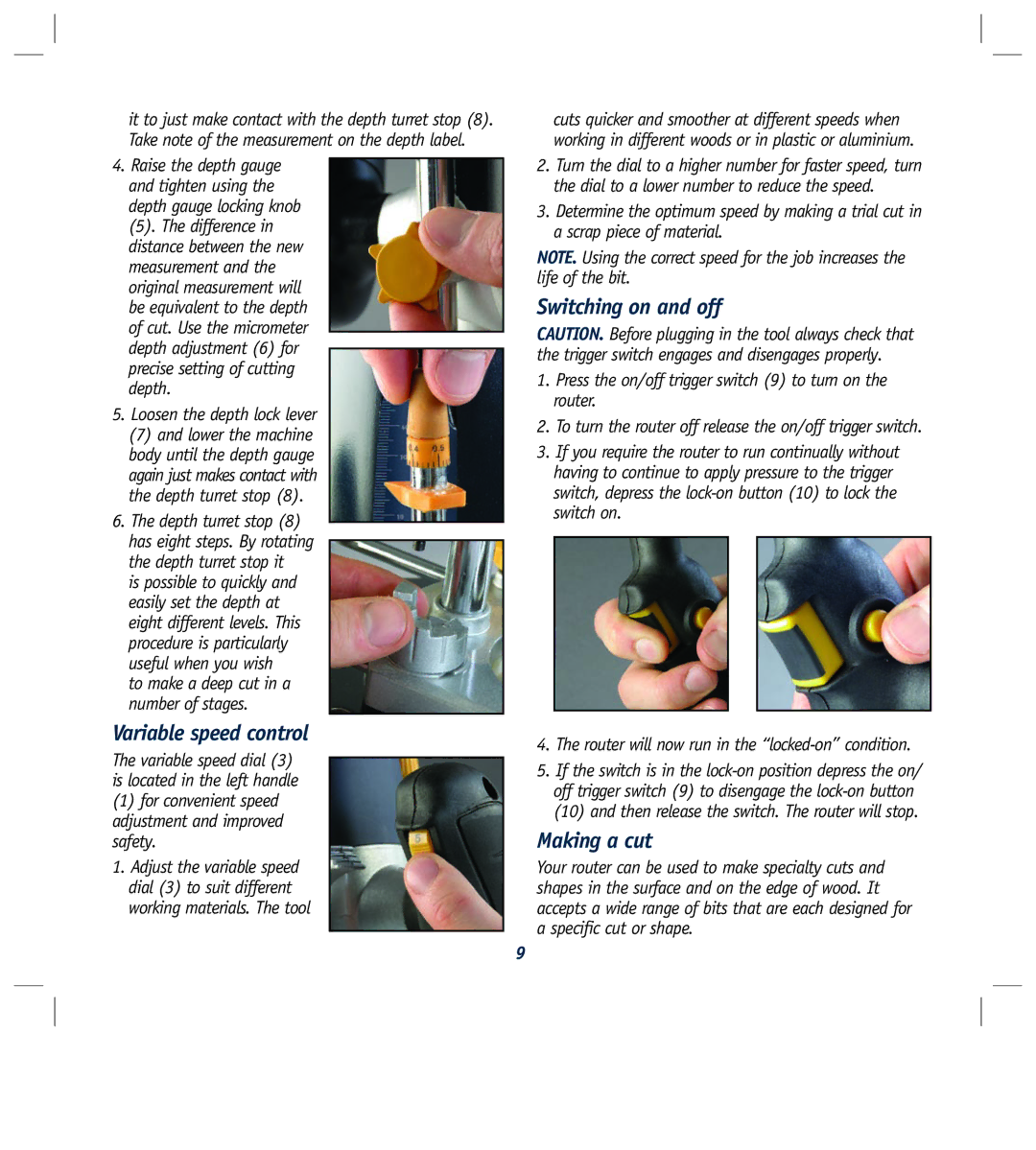

4.Raise the depth gauge and tighten using the depth gauge locking knob

(5).The difference in distance between the new measurement and the original measurement will be equivalent to the depth of cut. Use the micrometer depth adjustment (6) for precise setting of cutting depth.

5.Loosen the depth lock lever

(7)and lower the machine body until the depth gauge again just makes contact with the depth turret stop (8).

6.The depth turret stop (8) has eight steps. By rotating the depth turret stop it

is possible to quickly and easily set the depth at eight different levels. This procedure is particularly useful when you wish to make a deep cut in a number of stages.

Variable speed control

The variable speed dial (3) is located in the left handle

(1)for convenient speed adjustment and improved safety.

1.Adjust the variable speed dial (3) to suit different working materials. The tool

cuts quicker and smoother at different speeds when working in different woods or in plastic or aluminium.

2.Turn the dial to a higher number for faster speed, turn the dial to a lower number to reduce the speed.

3.Determine the optimum speed by making a trial cut in a scrap piece of material.

NOTE. Using the correct speed for the job increases the life of the bit.

Switching on and off

CAUTION. Before plugging in the tool always check that the trigger switch engages and disengages properly.

1.Press the on/off trigger switch (9) to turn on the router.

2.To turn the router off release the on/off trigger switch.

3.If you require the router to run continually without having to continue to apply pressure to the trigger switch, depress the

4.The router will now run in the

5.If the switch is in the

Making a cut

Your router can be used to make specialty cuts and shapes in the surface and on the edge of wood. It accepts a wide range of bits that are each designed for a specific cut or shape.

9