Rotation only mode of operation

Set the selector knob (4) to the ![]()

![]() position and the hammer function switch (7) to the right

position and the hammer function switch (7) to the right ![]() position.

position.

Rotary hammer mode of operation

Set the selector knob (4) to the ![]()

![]() position and the hammer function switch (7) to the left

position and the hammer function switch (7) to the left ![]()

![]() position.

position.

Hammer only mode of operation

Set the selector knob (4) to the ![]() position and the hammer function switch (7) to the left

position and the hammer function switch (7) to the left ![]()

![]() position.

position.

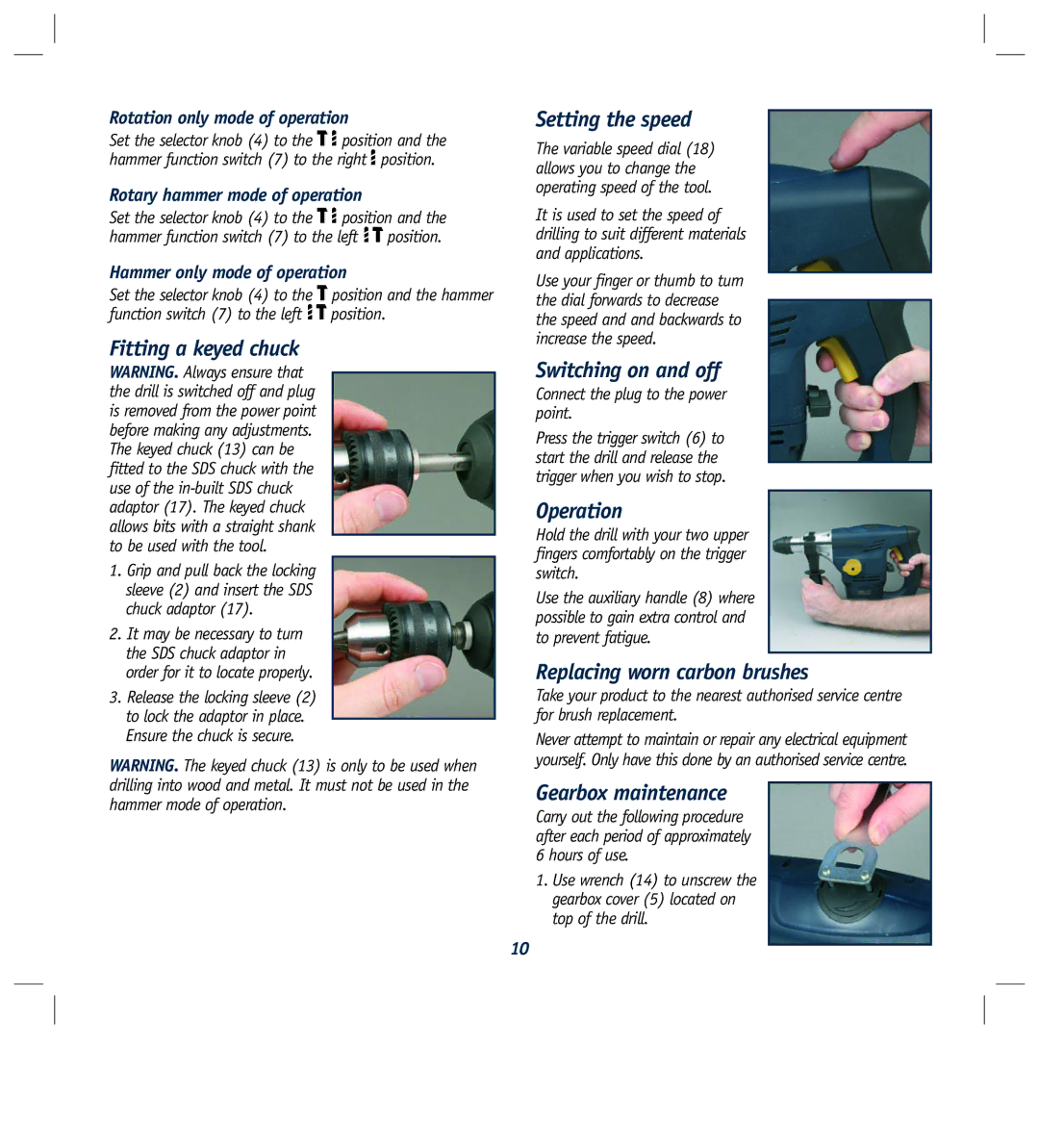

Fitting a keyed chuck

WARNING. Always ensure that the drill is switched off and plug is removed from the power point before making any adjustments. The keyed chuck (13) can be fitted to the SDS chuck with the use of the

1.Grip and pull back the locking sleeve (2) and insert the SDS chuck adaptor (17).

2.It may be necessary to turn the SDS chuck adaptor in order for it to locate properly.

3.Release the locking sleeve (2) to lock the adaptor in place. Ensure the chuck is secure.

WARNING. The keyed chuck (13) is only to be used when drilling into wood and metal. It must not be used in the hammer mode of operation.

Setting the speed

The variable speed dial (18) allows you to change the operating speed of the tool.

It is used to set the speed of drilling to suit different materials and applications.

Use your finger or thumb to turn the dial forwards to decrease the speed and and backwards to increase the speed.

Switching on and off

Connect the plug to the power point.

Press the trigger switch (6) to start the drill and release the trigger when you wish to stop.

Operation

Hold the drill with your two upper fingers comfortably on the trigger switch.

Use the auxiliary handle (8) where possible to gain extra control and to prevent fatigue.

Replacing worn carbon brushes

Take your product to the nearest authorised service centre for brush replacement.

Never attempt to maintain or repair any electrical equipment yourself. Only have this done by an authorised service centre.

Gearbox maintenance

Carry out the following procedure after each period of approximately 6 hours of use.

1.Use wrench (14) to unscrew the gearbox cover (5) located on top of the drill.

10