Fitting the magnetic bit holder

Hex head screws, hex bits and magnetic bit holders such as that supplied as accessories can be fitted into the clutch of the tool.

When fitting a hex head screw, adjust the driving depth so that the distance between the underside of the screw head and the outer rim of the nose piece is

Insert the end of the hex shaft of the bit holder (11) into the hex socket of the clutch housing

of the tool.

Note. Other accessories with a 6.35mm hex shaft can be purchased for use with this tool.

Fitting the adjustment collar and nose cone assembly

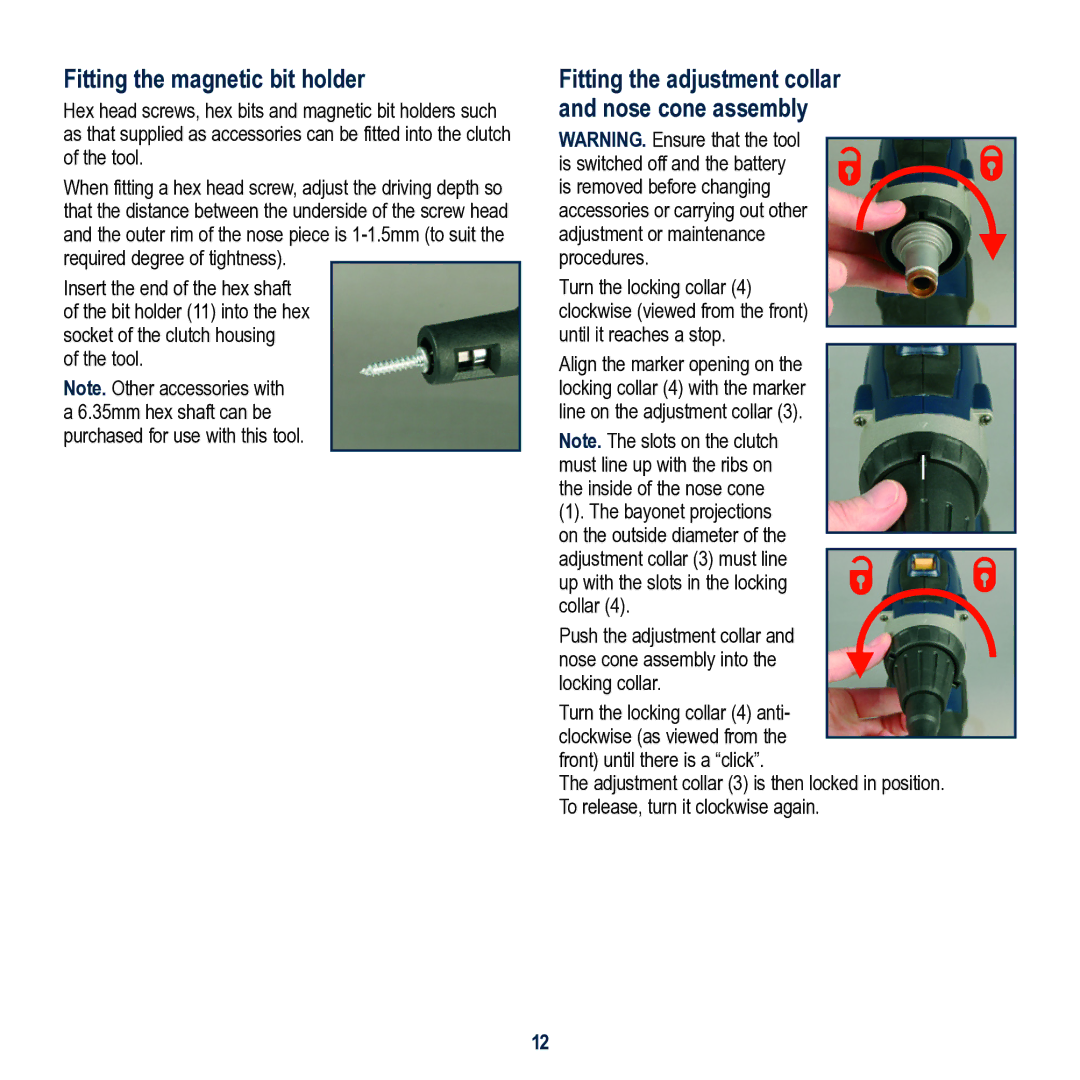

WARNING. Ensure that the tool

is switched off and the battery is removed before changing

accessories or carrying out other adjustment or maintenance procedures.

Turn the locking collar (4) clockwise (viewed from the front) until it reaches a stop.

Align the marker opening on the locking collar (4) with the marker line on the adjustment collar (3).

Note. The slots on the clutch must line up with the ribs on the inside of the nose cone

(1). The bayonet projections on the outside diameter of the

adjustment collar (3) must line up with the slots in the locking collar (4).

Push the adjustment collar and nose cone assembly into the locking collar.

Turn the locking collar (4) anti- clockwise (as viewed from the front) until there is a “click”.

The adjustment collar (3) is then locked in position. To release, turn it clockwise again.

12