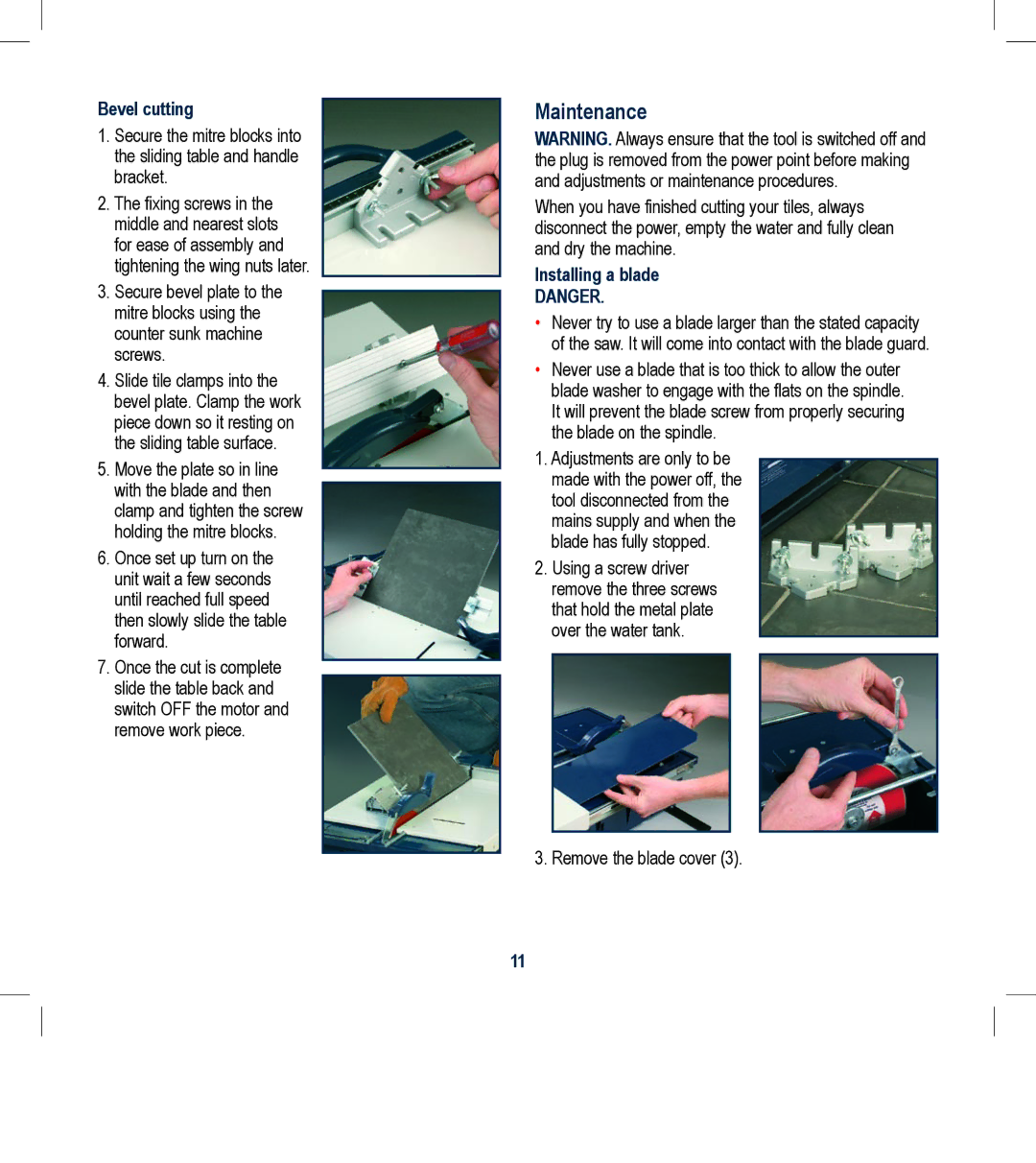

Bevel cutting

1.Secure the mitre blocks into the sliding table and handle bracket.

2.The fixing screws in the middle and nearest slots for ease of assembly and tightening the wing nuts later.

3.Secure bevel plate to the mitre blocks using the counter sunk machine screws.

4.Slide tile clamps into the bevel plate. Clamp the work piece down so it resting on the sliding table surface.

5.Move the plate so in line with the blade and then clamp and tighten the screw holding the mitre blocks.

6.Once set up turn on the unit wait a few seconds until reached full speed then slowly slide the table forward.

7.Once the cut is complete slide the table back and switch OFF the motor and remove work piece.

Maintenance

WARNING. Always ensure that the tool is switched off and the plug is removed from the power point before making and adjustments or maintenance procedures.

When you have finished cutting your tiles, always disconnect the power, empty the water and fully clean and dry the machine.

Installing a blade

DANGER.

•Never try to use a blade larger than the stated capacity of the saw. It will come into contact with the blade guard.

•Never use a blade that is too thick to allow the outer blade washer to engage with the flats on the spindle. It will prevent the blade screw from properly securing the blade on the spindle.

1.Adjustments are only to be made with the power off, the tool disconnected from the mains supply and when the blade has fully stopped.

2.Using a screw driver remove the three screws that hold the metal plate over the water tank.

3. Remove the blade cover (3).

11