GHS8, GDS8 specifications

Goodman Manufacturing, a well-reputed name in the HVAC industry, offers a comprehensive range of heating and cooling solutions. Among their notable products are the GDS8, GHS8, and GMS8 series, each designed to meet diverse customer needs while providing exceptional performance and energy efficiency.The Goodman GDS8 gas furnace is known for its remarkable efficiency and reliability. Boasting an AFUE (Annual Fuel Utilization Efficiency) rating of up to 80%, the GDS8 converts a significant portion of fuel into usable heat, ensuring lower energy bills for homeowners. This model features a multi-speed blower motor that optimizes airflow, enhancing temperature consistency throughout the home, and reducing noise levels during operation. The GDS8 comes equipped with a durable heat exchanger crafted from high-quality steel, ensuring longevity and optimal heat transfer.

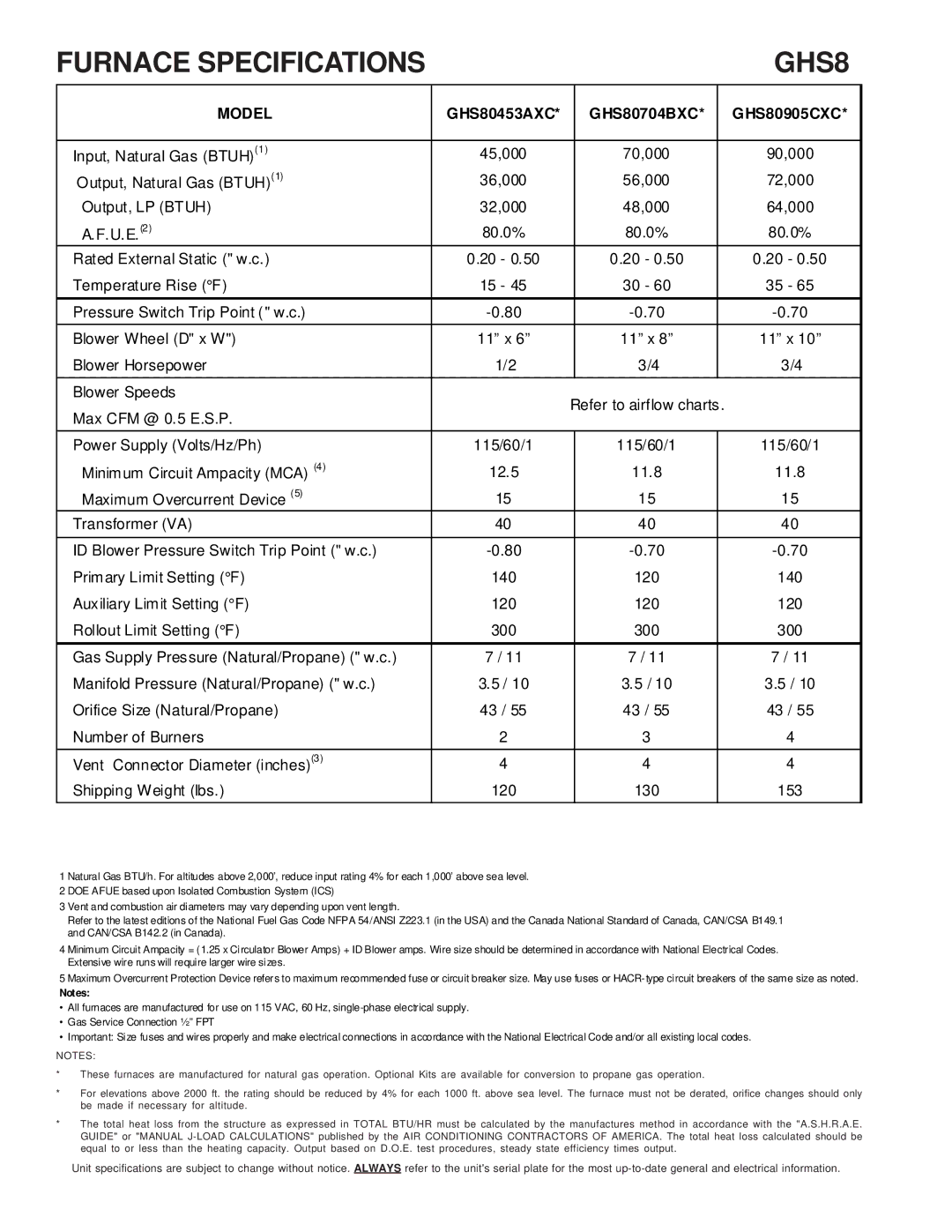

On the other hand, the GHS8 series represents Goodman’s commitment to high-efficiency heating. With an AFUE rating of up to 96%, the GHS8 is engineered for maximum performance. Its two-stage heating system allows for better temperature control, enabling the furnace to operate quietly and efficiently. Another standout feature is the ComfortBridge technology, which enhances the system’s ability to communicate and adapt to the home’s specific heating needs. This feature optimizes energy usage and increases comfort levels in any environment.

The Goodman GMS8 model is an exceptional choice for homeowners looking for a reliable gas furnace with a focus on energy efficiency. Similar to its counterparts, the GMS8 also delivers an AFUE of up to 96.5%. This unit features an advanced modulating gas valve that adjusts heating output based on the temperature requirements, creating a consistent and comfortable indoor climate. The GMS8 is also equipped with a high-efficiency ECM blower motor, which reduces energy consumption while improving airflow.

All three models feature Goodman’s quality construction, including a heavy-gauge cabinet that minimizes noise and enhances durability. They also are backed by Goodman’s limited lifetime warranty on the heat exchanger and a 10-year limited warranty on parts, providing customers with peace of mind regarding their investment. These furnaces are designed with efficiency and comfort in mind, making the GDS8, GHS8, and GMS8 ideal choices for homeowners looking to enhance their indoor environment while keeping energy costs in check.