CONDENSING AC UNIT SINGLE / THREE PHASE AIR CONDITIONERS, IO-402G specifications

Goodman Manufacturing's IO-402G is a prominent model in the realm of condensing air conditioning units, designed to serve both residential and commercial applications effectively. This unit stands out due to its robust construction and impressive energy efficiency, making it a reliable choice for air conditioning needs.One of the main features of the IO-402G is its versatile power options, available in both single and three-phase configurations. This adaptability allows it to meet various electrical requirements, ensuring compatibility with different installation environments. The unit's design incorporates a high-efficiency scroll compressor, which not only optimizes cooling performance but also enhances durability while significantly reducing operational noise.

The IO-402G is equipped with advanced refrigerant management technology, utilizing R-410A refrigerant, which is environmentally friendly and delivers superior cooling efficiency compared to older refrigerants. This feature reflects Goodman’s commitment to sustainability while also aligning with regulatory changes in refrigerant usage. The unit’s efficiency is further complemented by a high SEER (Seasonal Energy Efficiency Ratio) rating, positioning it among the more energy-efficient systems available in the market today.

In terms of construction, the IO-402G boasts a durable cabinet designed to withstand various weather conditions, featuring a powder-coated finish that resists corrosion and fading. The unit also includes sound-dampening technology to minimize operational noise, ensuring that it operates quietly even in residential settings.

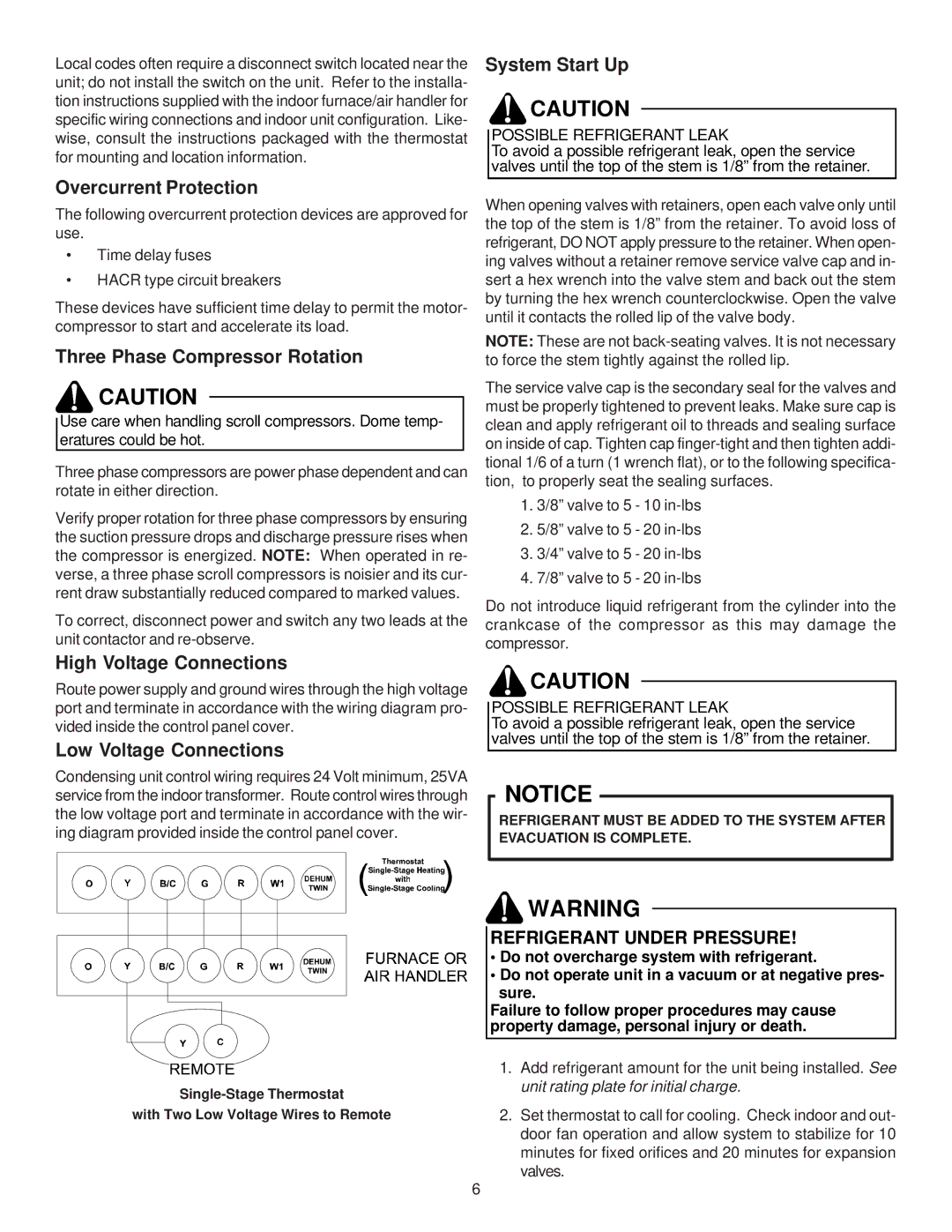

Additionally, the IO-402G provides easy access for service and maintenance, thanks to a user-friendly design that simplifies troubleshooting and repairs. The system is also compatible with a range of Goodman’s thermostats and controls, which can enhance user experience through smart technology and programmable settings.

Furthermore, Goodman’s commitment to quality is reflected in the warranty coverage available with the IO-402G, typically offering a generous limited warranty on parts, underscoring the manufacturer’s confidence in the unit’s longevity and performance.

Overall, the Goodman IO-402G condensing AC unit is an excellent choice for those seeking a reliable, efficient, and durable air conditioning solution for both residential and commercial applications. Its innovative design and thoughtful features make it a standout model in Goodman’s lineup, ensuring comfort and satisfaction for users all year round.