How Desiccant Air Drying System Works

How Desiccant Air Drying System Works

AIR WET IN

AIR

DRY

OUT

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() flange

flange

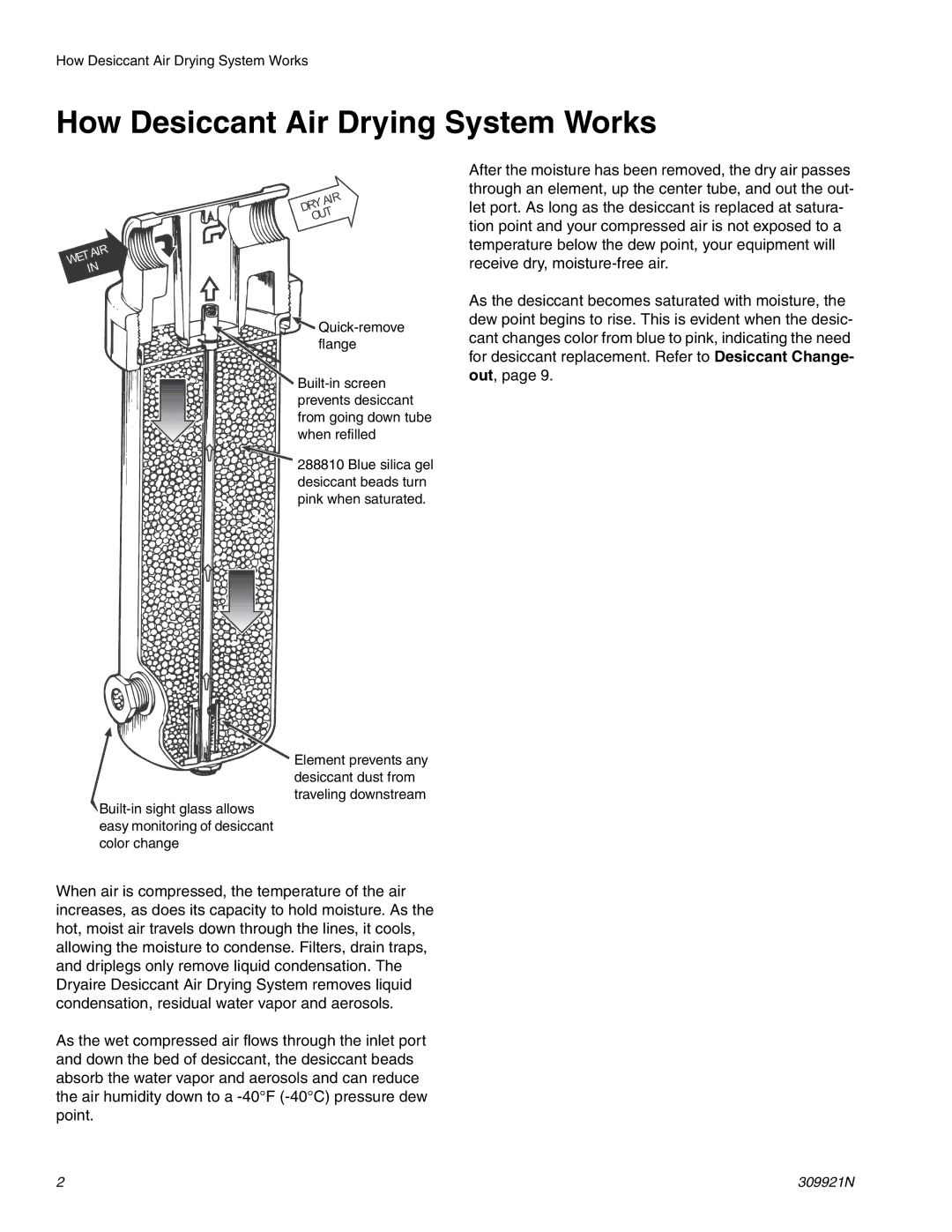

288810 Blue silica gel desiccant beads turn pink when saturated.

After the moisture has been removed, the dry air passes through an element, up the center tube, and out the out- let port. As long as the desiccant is replaced at satura- tion point and your compressed air is not exposed to a temperature below the dew point, your equipment will receive dry,

As the desiccant becomes saturated with moisture, the dew point begins to rise. This is evident when the desic- cant changes color from blue to pink, indicating the need for desiccant replacement. Refer to Desiccant Change- out, page 9.

Element prevents any desiccant dust from traveling downstream

When air is compressed, the temperature of the air increases, as does its capacity to hold moisture. As the hot, moist air travels down through the lines, it cools, allowing the moisture to condense. Filters, drain traps, and driplegs only remove liquid condensation. The Dryaire Desiccant Air Drying System removes liquid condensation, residual water vapor and aerosols.

As the wet compressed air flows through the inlet port and down the bed of desiccant, the desiccant beads absorb the water vapor and aerosols and can reduce the air humidity down to a

2 | 309921N |