Repair

Repair

Shut down proportioner and allow chemicals to cool before performing any repair proce- dures.

Clean Center Line Components using Gun Service Kit prior to performing any repair pro- cedures.

Filter Screen Removal and Service

1.Perform Pressure Relief Procedure (page 13) and Clean Spray Gun Procedure, page 18.

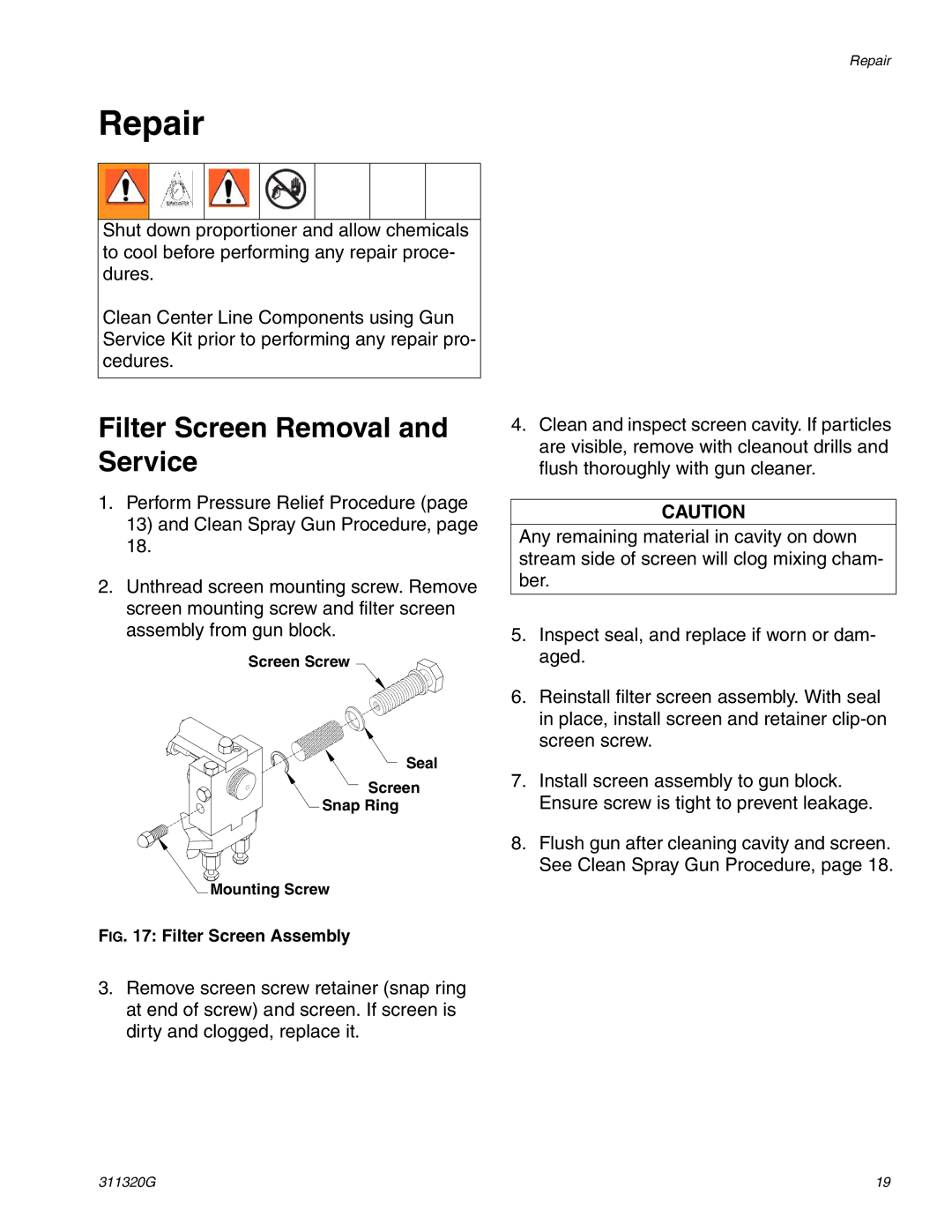

2.Unthread screen mounting screw. Remove screen mounting screw and filter screen assembly from gun block.

Screen Screw

Seal

Screen

Snap Ring

Mounting Screw

FIG. 17: Filter Screen Assembly

3.Remove screen screw retainer (snap ring at end of screw) and screen. If screen is dirty and clogged, replace it.

4.Clean and inspect screen cavity. If particles are visible, remove with cleanout drills and flush thoroughly with gun cleaner.

CAUTION

Any remaining material in cavity on down stream side of screen will clog mixing cham- ber.

5.Inspect seal, and replace if worn or dam- aged.

6.Reinstall filter screen assembly. With seal in place, install screen and retainer

7.Install screen assembly to gun block. Ensure screw is tight to prevent leakage.

8.Flush gun after cleaning cavity and screen. See Clean Spray Gun Procedure, page 18.

311320G | 19 |