1007, 226-813, 307-308 specifications

Graco Inc is a prominent player in the fluid management industry, known for its innovative solutions that span various sectors, including industrial, commercial, and residential markets. Among its extensive lineup, the Graco Inc 1007,307-308,226-813 models stand out due to their specialized features and advanced technologies, catering to the needs of professionals seeking efficiency and reliability.The Graco Inc 1007 model is designed for maximum performance, primarily aimed at handling high-pressure applications. This model excels in delivering precision and control, making it ideal for paint sprayers and other fluid dispensing tools. Its robust construction ensures durability, allowing it to withstand the rigors of daily use, while its compact design improves maneuverability in tight spaces.

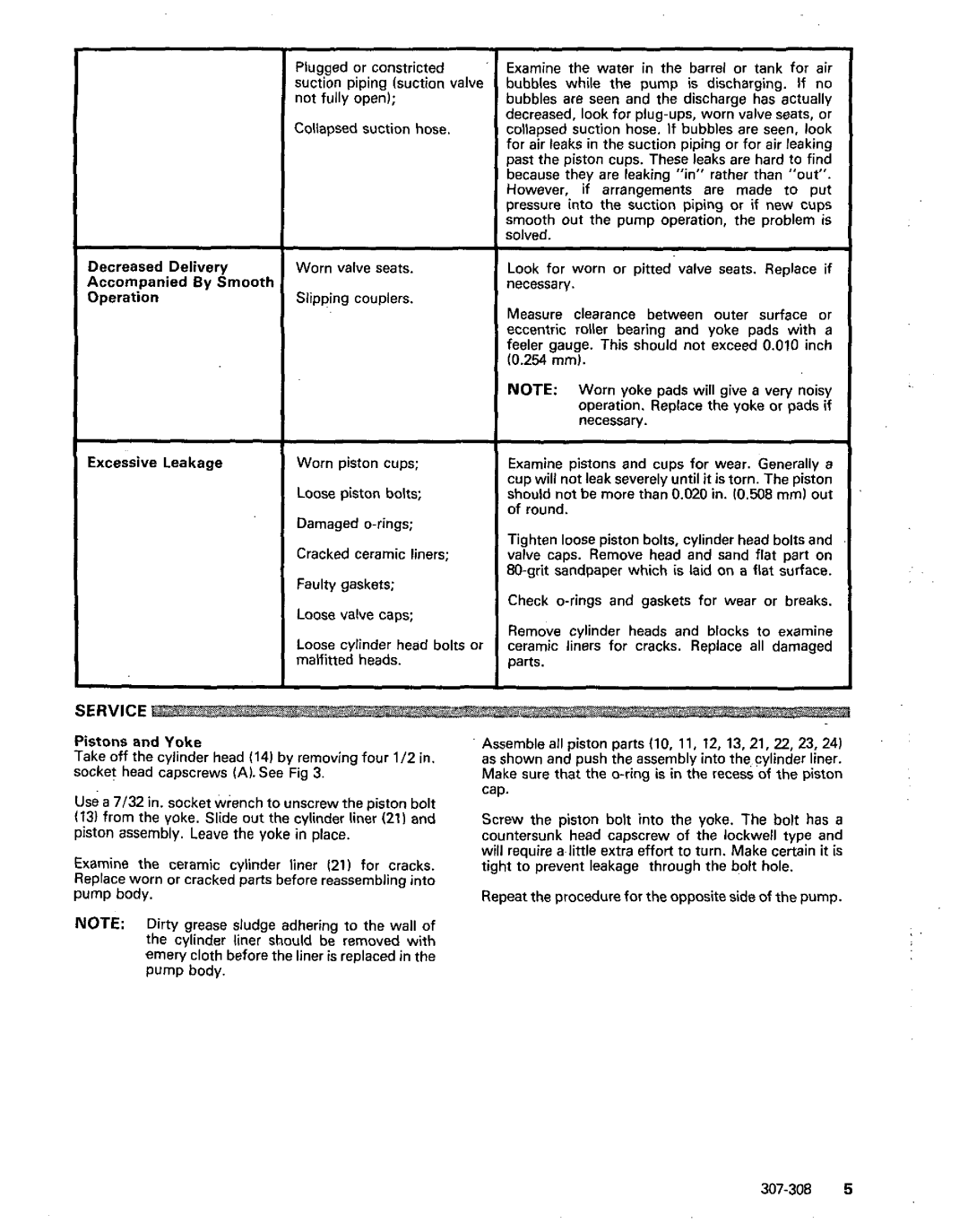

The 307-308 models come equipped with cutting-edge technologies that enhance user experience and operational efficiency. These models leverage advanced pump technologies, ensuring consistent flow and pressure, which is critical for tasks requiring meticulous accuracy. Additionally, the inclusion of automated features reduces the manual workload, allowing users to focus on other essential tasks.

One of the notable characteristics of the Graco 226-813 is its versatility. This model can handle a variety of fluids, from thick coatings to thin varnishes, making it a favorite among contractors and DIY enthusiasts alike. Its easy-to-use interface allows for quick adjustments to accommodate different materials without compromising quality. Moreover, the Graco 226-813 incorporates an efficient filtration system that minimizes clogs, ensuring a smooth and uninterrupted flow during operations.

All Graco Inc models emphasize safety and ergonomics. The incorporation of safety features protects users during operation, while ergonomic designs reduce fatigue during extended use. This balance of safety and comfort ensures that professionals can rely on Graco products for prolonged periods without adverse effects.

Furthermore, Graco Inc's commitment to sustainability is reflected in its technology, which promotes efficient resource usage, minimizing waste and environmental impact. The company continues to innovate, pushing the boundaries of fluid management technology to meet the evolving demands of various industries.

In conclusion, Graco Inc 1007, 307-308, and 226-813 models exemplify the company's dedication to quality and innovation. Their main features, advanced technologies, and user-centric characteristics make them invaluable tools for professionals navigating the demands of fluid management in today's fast-paced environments.