Operation

Air Switch Hand Held Valve

The valve operation is such that there are only two valve conditions: either fully open or fully closed.

The valve is opened and closed by the internal air control valve. Trigger the gun to open the valve. Release the trigger to close the valve.

Shaft Stroke Adjustment (Models 965766, 965767, 965768, and 965786 only)

Adjust the shaft stroke to balance the valve between

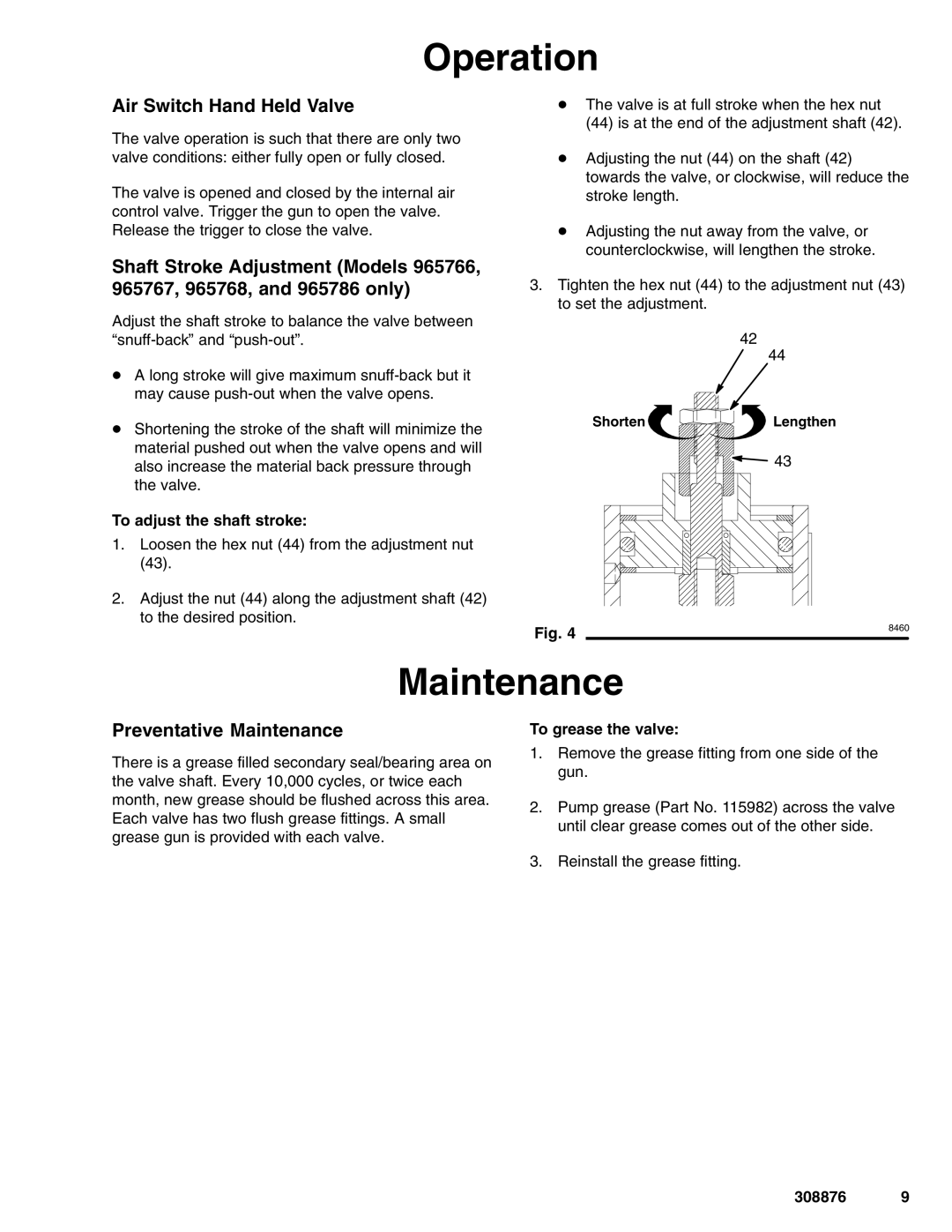

DThe valve is at full stroke when the hex nut

(44)is at the end of the adjustment shaft (42).

DAdjusting the nut (44) on the shaft (42) towards the valve, or clockwise, will reduce the stroke length.

DAdjusting the nut away from the valve, or counterclockwise, will lengthen the stroke.

3.Tighten the hex nut (44) to the adjustment nut (43) to set the adjustment.

42

44

DA long stroke will give maximum

DShortening the stroke of the shaft will minimize the material pushed out when the valve opens and will also increase the material back pressure through the valve.

To adjust the shaft stroke:

1.Loosen the hex nut (44) from the adjustment nut (43).

2.Adjust the nut (44) along the adjustment shaft (42) to the desired position.

Shorten

Fig. 4

Lengthen

43 |

8460

Maintenance

Preventative Maintenance

There is a grease filled secondary seal/bearing area on the valve shaft. Every 10,000 cycles, or twice each month, new grease should be flushed across this area. Each valve has two flush grease fittings. A small grease gun is provided with each valve.

To grease the valve:

1.Remove the grease fitting from one side of the gun.

2.Pump grease (Part No. 115982) across the valve until clear grease comes out of the other side.

3.Reinstall the grease fitting.

308876 9