HRE-55, HRE-45, HRE-90, HRE-20 specifications

The Greenheck Fan HRE series, specifically the models HRE-20, HRE-90, HRE-55, and HRE-45, represents a blend of innovation and efficiency in the HVAC industry. Built for both commercial and industrial applications, these exhaust fans stand out due to their robust design and advanced operational features.One of the main features of the HRE series is its energy-efficient motor design. These fans come equipped with a premium efficiency motor that reduces energy consumption while maintaining high performance. The motors are specifically designed to provide exceptional airflow while operating at lower sound levels, ensuring a quieter environment.

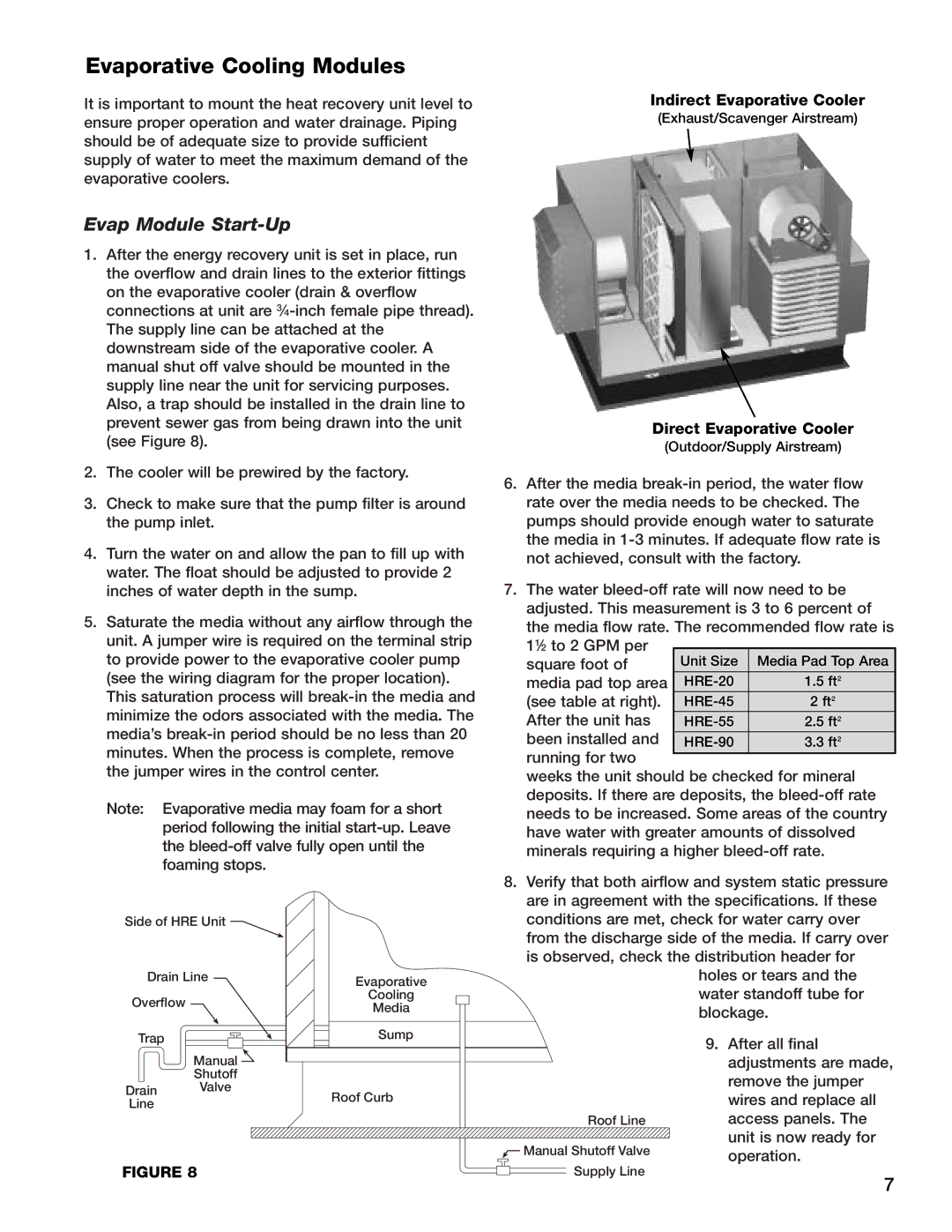

The HRE models also showcase advanced aerodynamic design, featuring optimized blade geometry that enhances airflow performance. This design ensures that the fans can deliver consistent and effective air movement even at varying operational conditions. This makes the HRE series suitable for use in a wide range of applications, from commercial kitchens to industrial processes.

Another significant characteristic of the HRE series is its durability. Constructed from high-quality materials, these fans are built to withstand harsh environmental conditions and prolonged usage. The robust casing and corrosion-resistant finishes ensure longevity, reducing the need for frequent repairs or replacements.

In terms of installation and maintenance, the HRE series offers significant advantages. The fans are designed for easy installation with clear mounting instructions. Additionally, maintenance procedures are simplified, allowing for hassle-free access to critical components, which reduces downtime and operating costs.

Technologically, the HRE models incorporate advanced controls and monitoring systems. These systems can offer real-time feedback on operational performance, allowing for proactive maintenance and energy management. Integrated controls can be customized to work with building management systems, providing users with seamless integration and control capabilities.

Overall, the Greenheck Fan HRE-20, HRE-90, HRE-55, and HRE-45 exemplify a commitment to quality and efficiency in commercial and industrial ventilation solutions. Their combination of energy efficiency, advanced design, durability, and user-friendly features make them a leading choice for those seeking reliable airflow solutions. These fans not only meet current industry standards but also set a benchmark for performance and innovation in the HVAC sector.