SWB, SFD, SFB specifications

Greenheck Fan’s SFB, SFD, and SWB series represent advanced solutions in ventilation technology, designed to cater to a variety of commercial and industrial applications. Each series brings unique features and optimizations that enhance airflow efficiency and reliability, making them suitable for schools, warehouses, and manufacturing facilities.The SFB series stands out with its durable construction and high-performance capabilities. These fans are engineered for direct drive applications, offering quieter operation and lower maintenance compared to belt-driven alternatives. The SFB series features efficient backward-inclined airfoil blades, which minimize energy consumption while maximizing airflow. Additionally, they are designed with an innovative airflow path that reduces turbulence and improves overall performance.

In contrast, the SFD series is intended for applications requiring high static pressure capabilities. It incorporates a special housing design that allows for increased efficiency in high-pressure environments. The advanced motor technology in the SFD series contributes to significant energy savings, while the unit's adjustable pitch blades ensure optimal performance across various operating conditions. These fans are particularly popular in commercial kitchen exhaust systems, where effective removal of smoke and odors is critical.

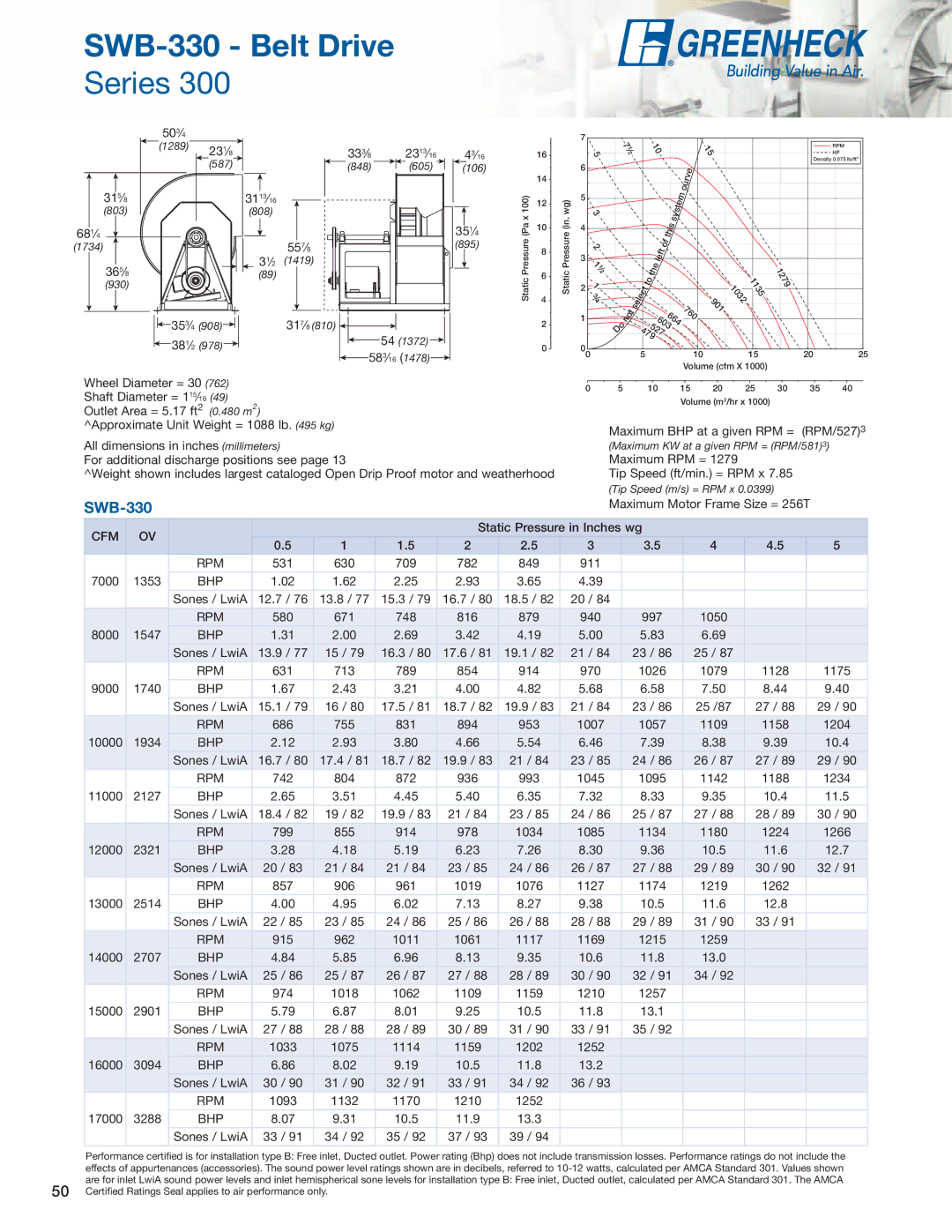

The SWB series, meanwhile, is specifically designed for sidewall applications, making it a versatile option for residential and light commercial use. The SWB fans feature a compact design that facilitates easy installation in tight spaces, and their weather-resistant construction ensures reliable performance even in challenging outdoor conditions. Additionally, these fans utilize energy-efficient motor designs that further contribute to their low operational costs.

All three series prioritize user-friendly operation and maintenance. They are equipped with standard access panels that provide easy interior access for cleaning and servicing, thereby extending the lifespan of the equipment. Greenheck also emphasizes noise reduction in its designs, employing sound-dampening technologies and vibration isolation features to ensure a quieter operation.

In conclusion, Greenheck Fan’s SFB, SFD, and SWB series represent a commitment to innovation in ventilation technology. Their distinctive characteristics, including energy efficiency, durability, and ease of maintenance, make them ideal choices in a wide array of applications, from industrial to residential settings. With ongoing advancements in technology, Greenheck continues to set benchmarks in the industry, ensuring effective air movement solutions that align with modern sustainability demands.