G0619 specifications

The Grizzly G0619 is an impressive milling machine that caters to both hobbyists and professional machinists looking for a reliable and compact solution for their machining needs. This versatile machine combines the capabilities of a milling machine with the functionality of a drill press, making it an invaluable tool in any workshop.One of the standout features of the Grizzly G0619 is its powerful 1 HP motor, which operates on 110V power supply, delivering plenty of torque for various machining tasks. The machine has a variable speed range of 0 to 2,000 RPM, allowing users to adjust settings for different materials and levels of precision. With its belt drive system, the G0619 ensures smooth operation and reduced maintenance, providing a seamless user experience.

The machine’s precision dovetail column design contributes to its stability and accuracy. Users appreciate the easy-to-read digital depth gauge and the adjustable vertical head, which allows for precise drilling and milling at any angle. The table size of 9.5" by 32" offers ample working space, complemented by T-slots that enable secure workpiece clamping.

In terms of characteristics, the Grizzly G0619 is designed for ease of use, featuring handwheels and quick-release clamps for effortless adjustments. The machine also incorporates a built-in spindle lock, making it convenient for tool changes. Its weight of approximately 365 pounds ensures durability and stability during operations.

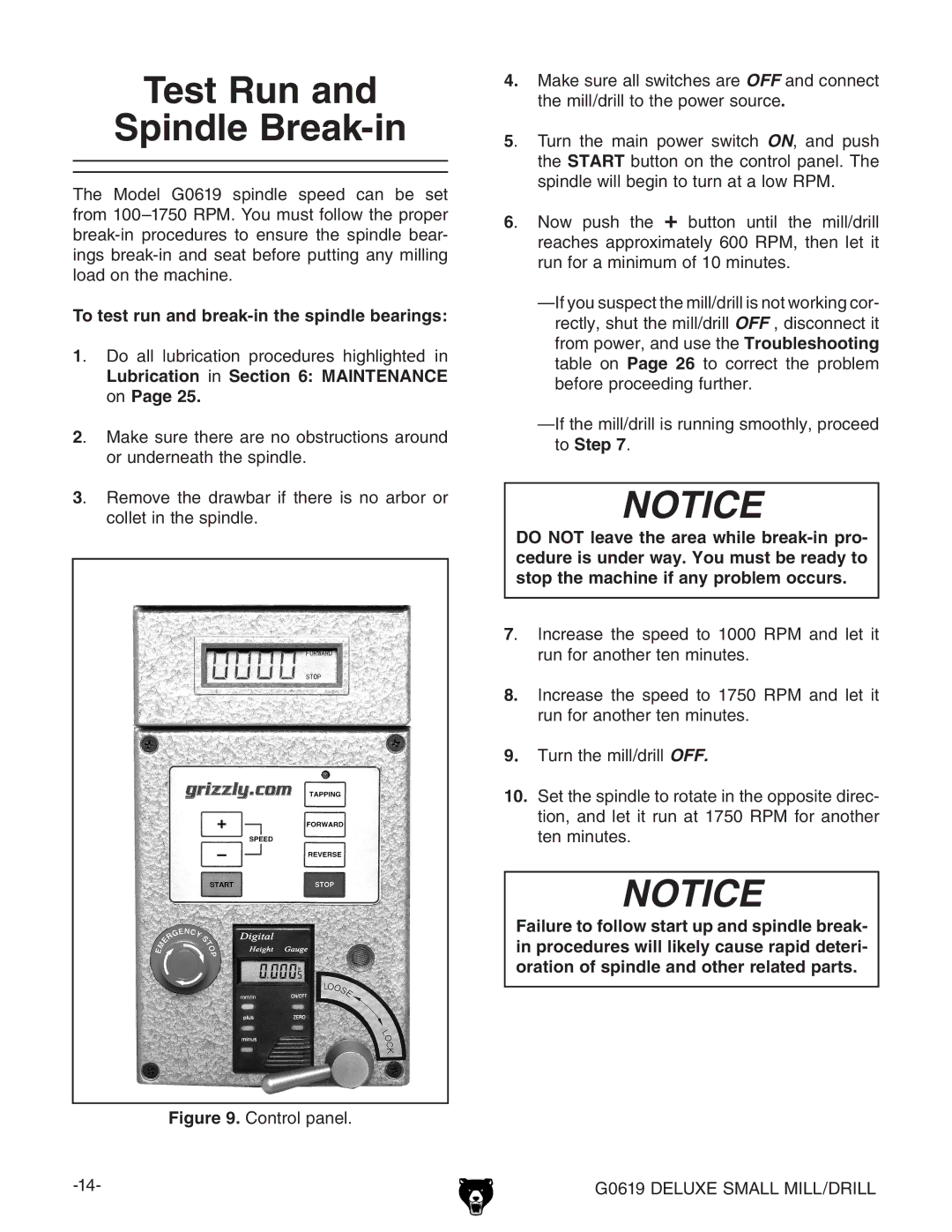

Technology-wise, the G0619 utilizes a digital readout (DRO) system that enhances accuracy and ease when positioning the milling cutter. This feature is particularly beneficial for intricate designs and repeatable precision work. Additionally, the machine's design emphasizes user safety, with safety guards and a straightforward operation manual.

Overall, the Grizzly G0619 is a robust milling machine that effectively combines user-friendly features with professional-grade capabilities. It is an ideal addition to any workshop, providing users with the tools needed to accomplish a wide variety of machining tasks with efficiency and precision. Whether you are a seasoned machinist or a passionate hobbyist, the G0619 stands out as a reliable and versatile option for your milling needs.