Buffing & Polishing

For buffing and polishing, Grizzly offers a broad line of buffing wheels and polishing compounds. Please refer to our current catalog. To buff or pol- ish:

1.Make sure the power cord is unplugged and remove the 13⁄8" hex nuts at the end of each shaft. Facing the machine, the

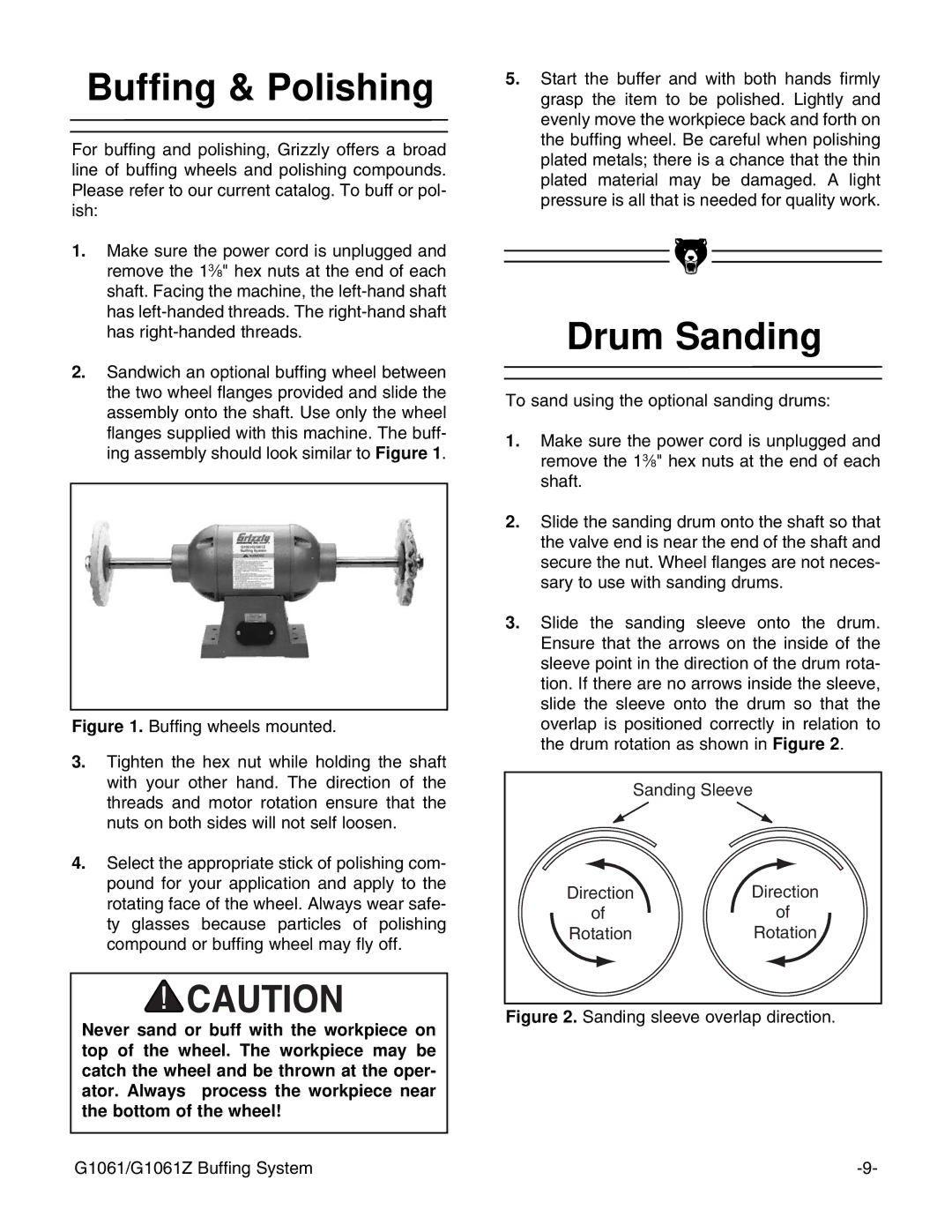

2.Sandwich an optional buffing wheel between the two wheel flanges provided and slide the assembly onto the shaft. Use only the wheel flanges supplied with this machine. The buff- ing assembly should look similar to Figure 1.

Figure 1. Buffing wheels mounted.

3.Tighten the hex nut while holding the shaft with your other hand. The direction of the threads and motor rotation ensure that the nuts on both sides will not self loosen.

4.Select the appropriate stick of polishing com- pound for your application and apply to the rotating face of the wheel. Always wear safe- ty glasses because particles of polishing compound or buffing wheel may fly off.

5.Start the buffer and with both hands firmly grasp the item to be polished. Lightly and evenly move the workpiece back and forth on the buffing wheel. Be careful when polishing plated metals; there is a chance that the thin plated material may be damaged. A light pressure is all that is needed for quality work.

Drum Sanding

To sand using the optional sanding drums:

1.Make sure the power cord is unplugged and remove the 13⁄8" hex nuts at the end of each shaft.

2.Slide the sanding drum onto the shaft so that the valve end is near the end of the shaft and secure the nut. Wheel flanges are not neces- sary to use with sanding drums.

3.Slide the sanding sleeve onto the drum. Ensure that the arrows on the inside of the sleeve point in the direction of the drum rota- tion. If there are no arrows inside the sleeve, slide the sleeve onto the drum so that the overlap is positioned correctly in relation to the drum rotation as shown in Figure 2.

Sanding Sleeve

Direction | Direction |

of | of |

Rotation | Rotation |

Never sand or buff with the workpiece on top of the wheel. The workpiece may be catch the wheel and be thrown at the oper- ator. Always process the workpiece near the bottom of the wheel!

Figure 2. Sanding sleeve overlap direction.

G1061/G1061Z Buffing System |