MODEL G1600 |

PNEUMATIC SANDING |

DRUM FOR MODEL G1495 |

INSTRUCTIONS |

Specifications |

|

|

| Mounting Bore | 1" x 12 TPI LH | ||

EYE INJURY HAZARD! | Length | 6" | ||||

Always wear safety glasses | Diameter | 4" | ||||

during | use to prevent | Air Inlet Type | Schrader Valve | |||

serious personal injury. |

| Maximum Pressure | 10 PSI | |||

|

|

| Inflation Method | Manual Pump Only | ||

10 PSI MAX |

|

|

|

|

| |

AIR PRESSURE! |

|

|

|

|

| |

Exceeding this PSI may |

| Inventory |

|

| ||

result in injury/tool damage. |

|

|

|

| ||

|

|

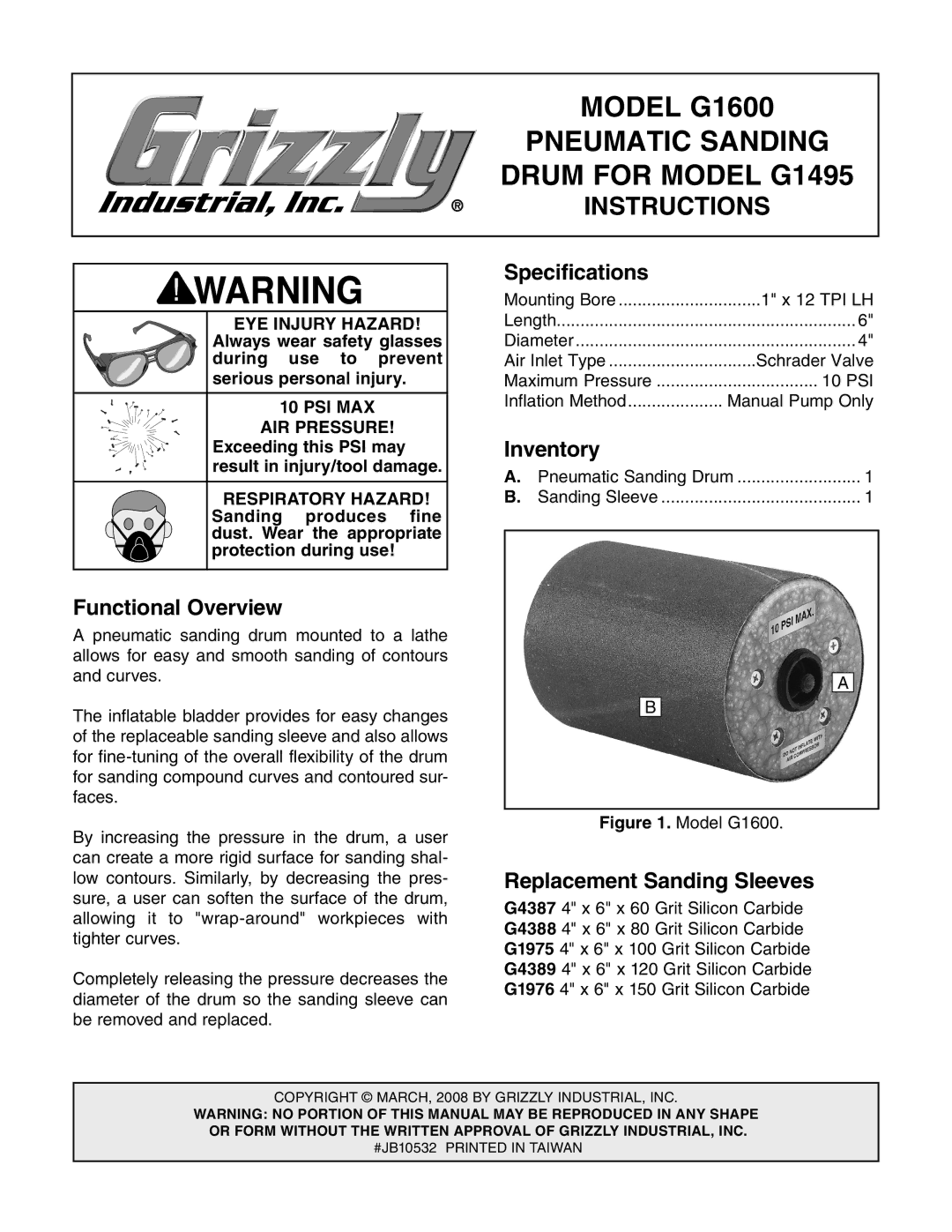

| A. | Pneumatic Sanding Drum | 1 | |

RESPIRATORY HAZARD! | B. | Sanding Sleeve | 1 | |||

Sanding | produces | fine |

|

|

|

|

dust. Wear the appropriate |

|

|

|

| ||

protection during use! |

|

|

|

|

| |

Functional Overview |

|

|

|

|

|

|

A pneumatic sanding drum mounted to a lathe |

|

|

|

| ||

allows for easy and smooth sanding of contours |

|

|

|

| ||

and curves. |

|

|

|

|

|

|

|

|

|

|

|

| A |

|

|

|

| B |

|

|

The inflatable bladder provides for easy changes |

|

|

|

| ||

of the replaceable sanding sleeve and also allows |

|

|

|

| ||

for |

|

|

|

| ||

for sanding compound curves and contoured sur- |

|

|

|

| ||

faces. |

|

|

|

|

|

|

|

|

|

| Figure 1. Model G1600. |

| |

By increasing the pressure in the drum, a user |

|

|

|

| ||

can create a more rigid surface for sanding shal- |

|

|

|

| ||

low contours. Similarly, by decreasing the pres- | Replacement Sanding Sleeves |

| ||||

sure, a user can soften the surface of the drum, |

|

|

|

| ||

|

|

| G4387 4" x 6" x 60 Grit Silicon Carbide |

| ||

allowing it to | with |

|

|

|

| |

|

|

| G4388 4" x 6" x 80 Grit Silicon Carbide |

| ||

tighter curves. |

|

|

|

|

|

|

|

|

| G1975 4" x 6" x 100 Grit Silicon Carbide |

| ||

|

|

| G4389 4" x 6" x 120 Grit Silicon Carbide |

| ||

Completely releasing the pressure decreases the |

|

|

|

| ||

|

|

| G1976 4" x 6" x 150 Grit Silicon Carbide |

| ||

diameter of the drum so the sanding sleeve can |

|

|

|

| ||

be removed and replaced. |

|

|

|

|

|

|

COPYRIGHT © MARCH, 2008 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#JB10532 PRINTED IN TAIWAN