Operation |

|

| Operation Tips | |

1. | DISCONNECT LATHE FROM POWER! |

| • Adjust the pressure in the drum to | |

|

|

|

| the firmness of the drum for sanding con- |

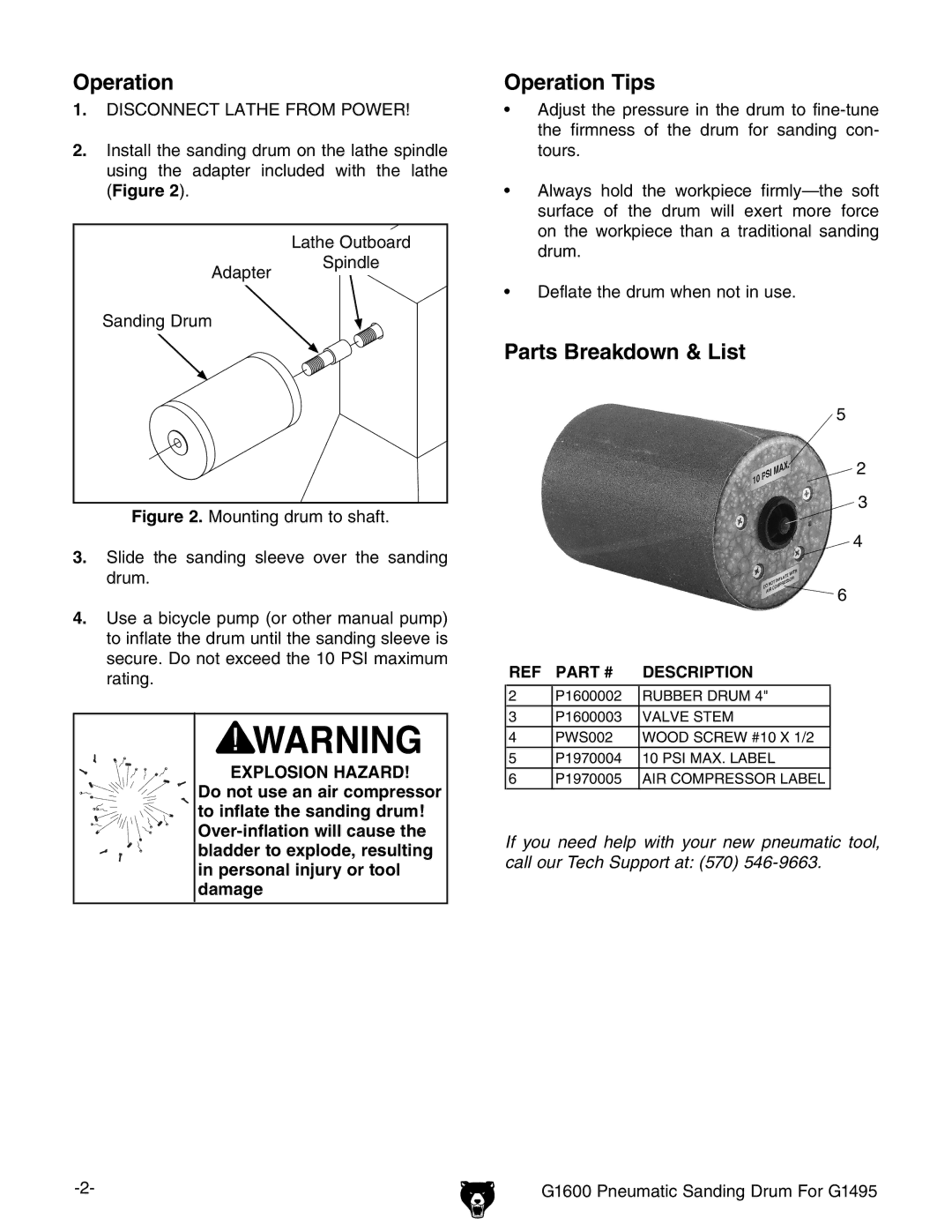

2. Install the sanding drum on the lathe spindle | tours. | |||

| using the adapter included with the | lathe |

| |

| (Figure 2). |

|

| • Always hold the workpiece |

|

|

|

| surface of the drum will exert more force |

|

| Lathe Outboard |

| on the workpiece than a traditional sanding |

|

|

| drum. | |

|

| Spindle |

| |

| Adapter |

|

| |

|

|

| • Deflate the drum when not in use. | |

|

|

|

| |

| Sanding Drum |

|

|

|

|

|

|

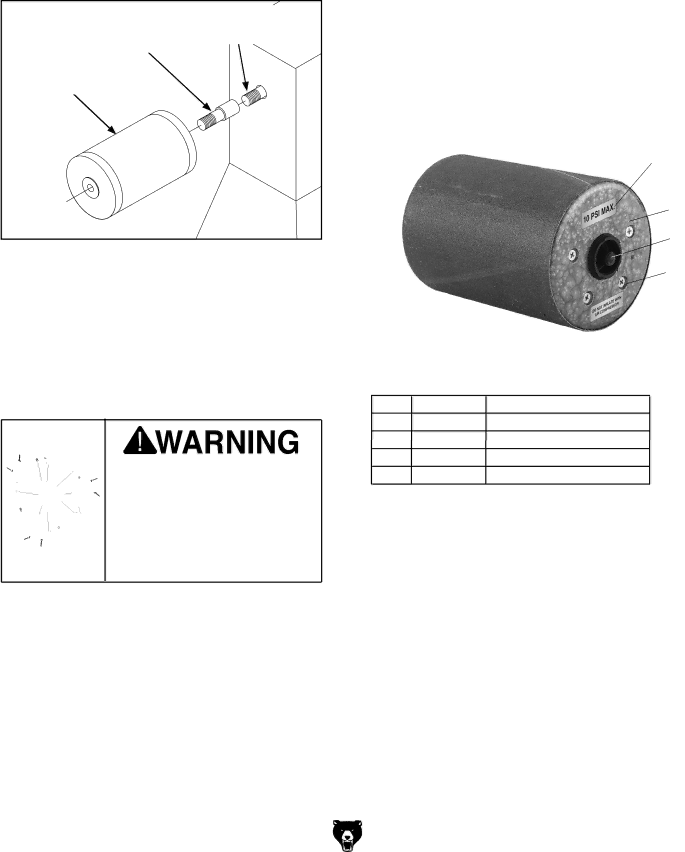

| Parts Breakdown & List |

|

|

|

| 5 |

|

|

|

| 2 |

| Figure 2. Mounting drum to shaft. |

| 3 | |

|

|

| ||

3.Slide the sanding sleeve over the sanding drum.

4.Use a bicycle pump (or other manual pump) to inflate the drum until the sanding sleeve is secure. Do not exceed the 10 PSI maximum rating.

4

![]() 6

6

REF PART # | DESCRIPTION |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() EXPLOSION HAZARD!

EXPLOSION HAZARD! ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Do not use an air compressor

Do not use an air compressor ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() to inflate the sanding drum!

to inflate the sanding drum! ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() bladder to explode, resulting in personal injury or tool damage

bladder to explode, resulting in personal injury or tool damage

2P1600002 RUBBER DRUM 4"

3P1600003 VALVE STEM

4PWS002 WOOD SCREW #10 X 1/2

5P1970004 10 PSI MAX. LABEL

6P1970005 AIR COMPRESSOR LABEL

If you need help with your new pneumatic tool, call our Tech Support at: (570)

G1600 Pneumatic Sanding Drum For G1495 |