Operation

Replacement Sanding Sleeves

1.DISCONNECT BUFFER FROM POWER!

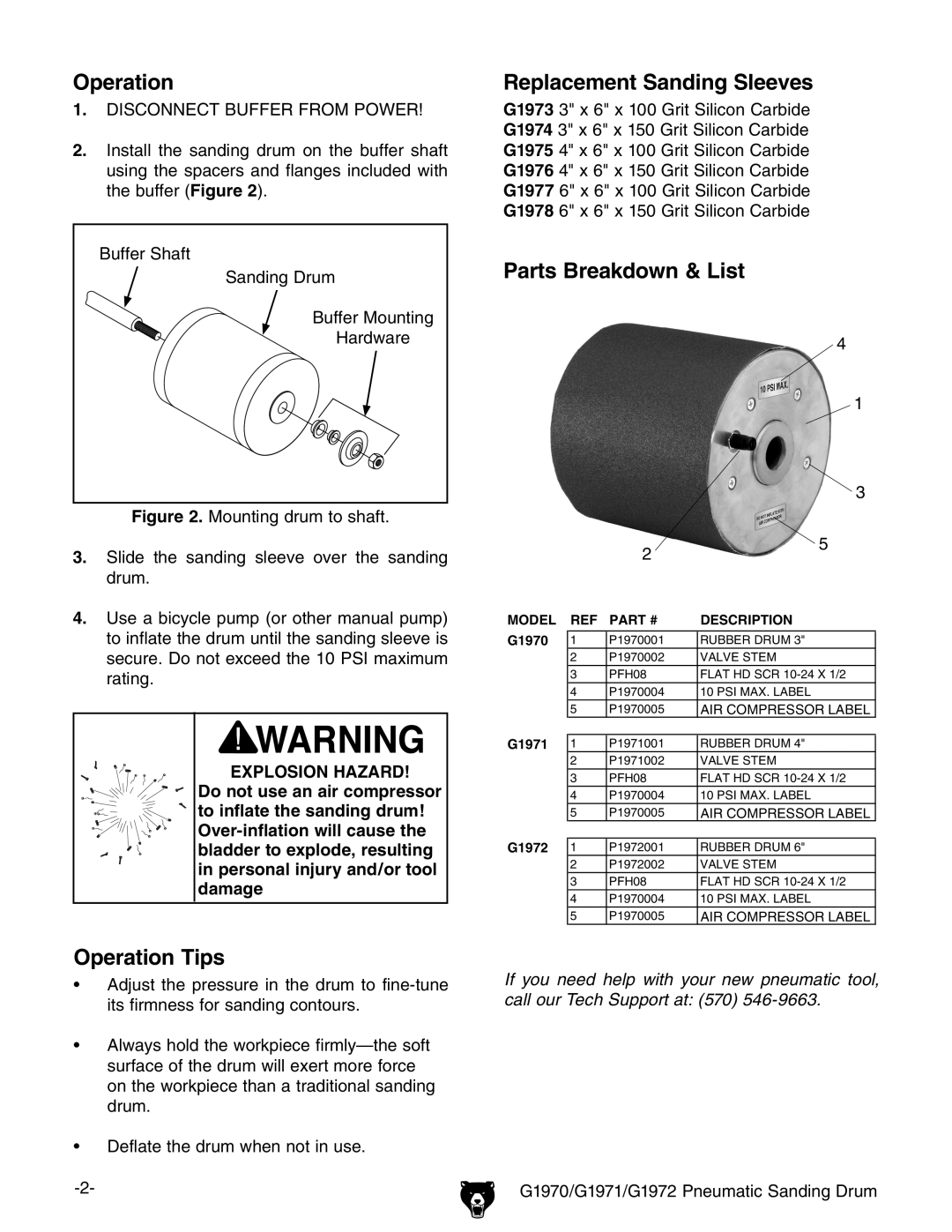

2.Install the sanding drum on the buffer shaft using the spacers and flanges included with the buffer (Figure 2).

G1973 3" x 6" x 100 Grit Silicon Carbide G1974 3" x 6" x 150 Grit Silicon Carbide G1975 4" x 6" x 100 Grit Silicon Carbide G1976 4" x 6" x 150 Grit Silicon Carbide G1977 6" x 6" x 100 Grit Silicon Carbide G1978 6" x 6" x 150 Grit Silicon Carbide

Buffer Shaft |

| Parts Breakdown & List |

| Sanding Drum | |

|

| |

| Buffer Mounting |

|

| Hardware | 4 |

|

| |

|

| 1 |

|

| 3 |

Figure 2. Mounting drum to shaft.

3.Slide the sanding sleeve over the sanding drum.

2 | 5 |

|

4.Use a bicycle pump (or other manual pump) to inflate the drum until the sanding sleeve is secure. Do not exceed the 10 PSI maximum rating.

EXPLOSION HAZARD! Do not use an air compressor to inflate the sanding drum!

Operation Tips

•Adjust the pressure in the drum to

its firmness for sanding contours.

MODEL | REF | PART # | DESCRIPTION |

G1970 | 1 | P1970001 | RUBBER DRUM 3" |

| 2 | P1970002 | VALVE STEM |

| 3 | PFH08 | FLAT HD SCR |

| 4 | P1970004 | 10 PSI MAX. LABEL |

5P1970005 AIR COMPRESSOR LABEL

G1971 | 1 | P1971001 | RUBBER DRUM 4" |

| 2 | P1971002 | VALVE STEM |

| 3 | PFH08 | FLAT HD SCR |

| 4 | P1970004 | 10 PSI MAX. LABEL |

5P1970005 AIR COMPRESSOR LABEL

G1972 | 1 | P1972001 | RUBBER DRUM 6" |

| 2 | P1972002 | VALVE STEM |

| 3 | PFH08 | FLAT HD SCR |

| 4 | P1970004 | 10 PSI MAX. LABEL |

5P1970005 AIR COMPRESSOR LABEL

If you need help with your new pneumatic tool, call our Tech Support at: (570)

•Always hold the workpiece

•Deflate the drum when not in use.

G1970/G1971/G1972 Pneumatic Sanding Drum |