Oiling Stapler

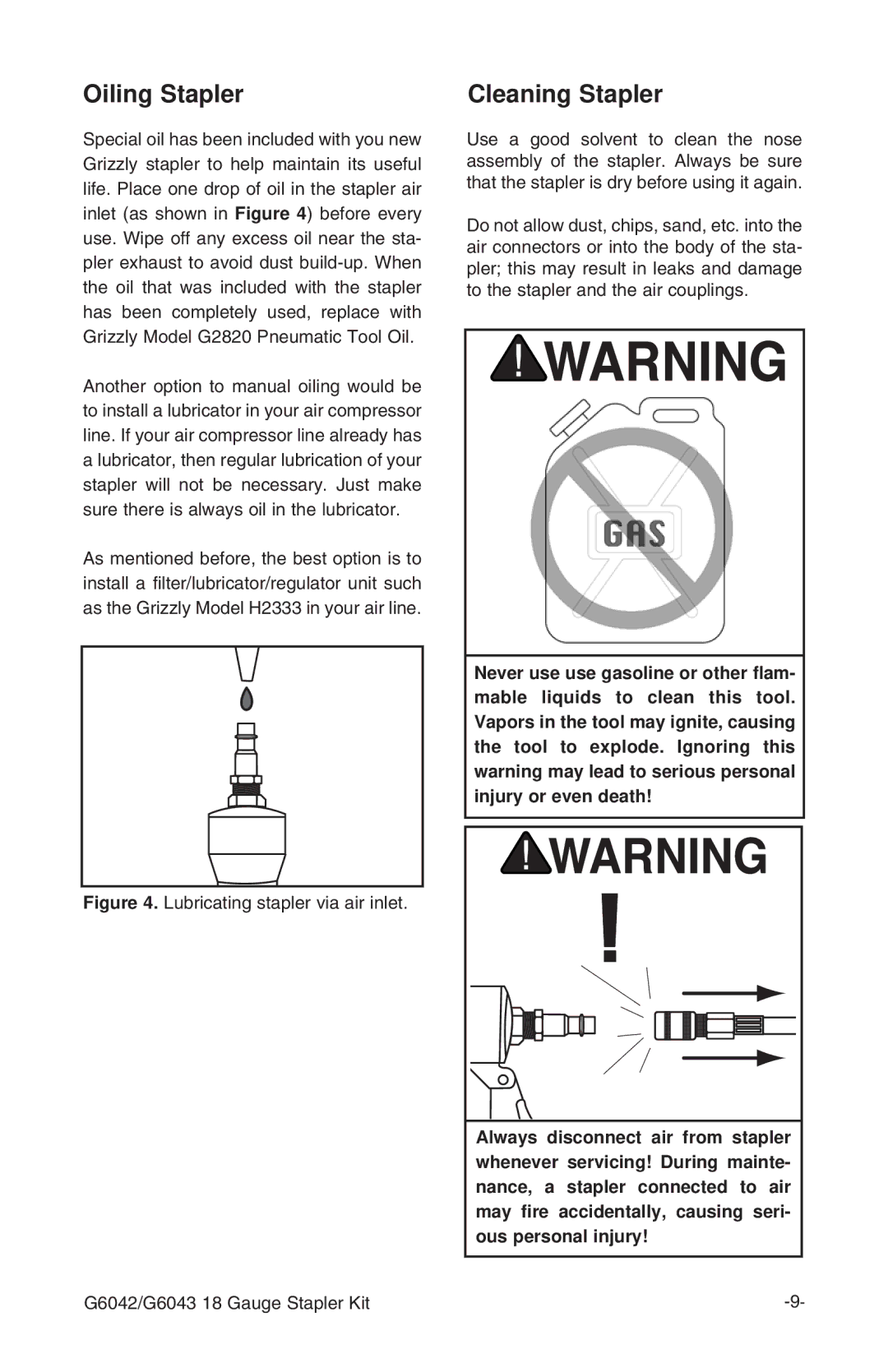

Special oil has been included with you new Grizzly stapler to help maintain its useful life. Place one drop of oil in the stapler air inlet (as shown in Figure 4) before every use. Wipe off any excess oil near the sta- pler exhaust to avoid dust

Another option to manual oiling would be to install a lubricator in your air compressor line. If your air compressor line already has a lubricator, then regular lubrication of your stapler will not be necessary. Just make sure there is always oil in the lubricator.

As mentioned before, the best option is to install a filter/lubricator/regulator unit such as the Grizzly Model H2333 in your air line.

Figure 4. Lubricating stapler via air inlet.

Cleaning Stapler

Use a good solvent to clean the nose assembly of the stapler. Always be sure that the stapler is dry before using it again.

Do not allow dust, chips, sand, etc. into the air connectors or into the body of the sta- pler; this may result in leaks and damage to the stapler and the air couplings.

Never use use gasoline or other flam- mable liquids to clean this tool. Vapors in the tool may ignite, causing the tool to explode. Ignoring this warning may lead to serious personal injury or even death!

Always disconnect air from stapler whenever servicing! During mainte- nance, a stapler connected to air may fire accidentally, causing seri- ous personal injury!

G6042/G6043 18 Gauge Stapler Kit |