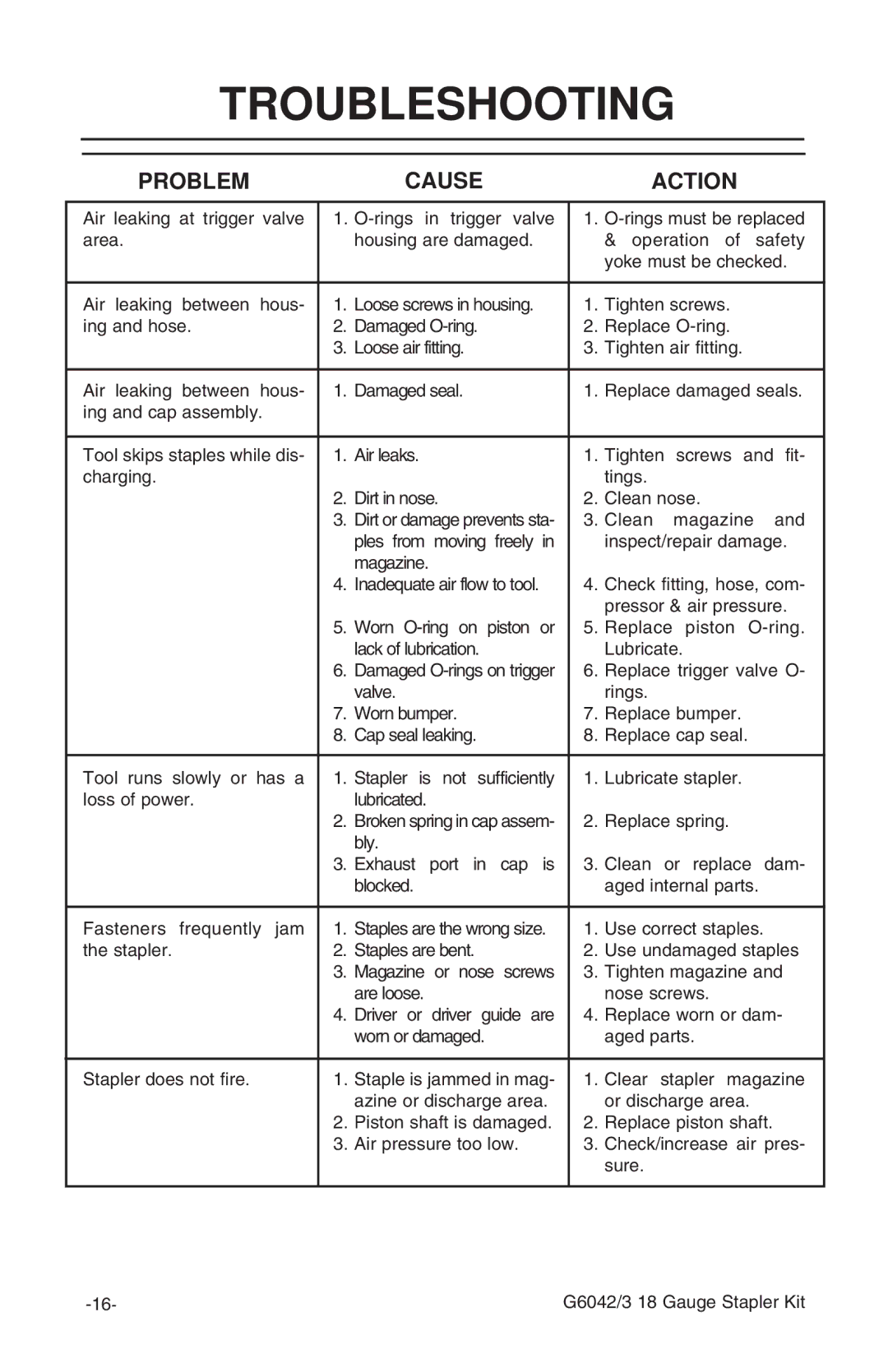

TROUBLESHOOTING

| PROBLEM |

|

|

| CAUSE |

| ACTION |

|

| ||||

| Air leaking at trigger valve |

|

| 1. |

|

| 1. |

| |||||

| area. |

|

|

| housing are damaged. |

|

|

| & operation | of | safety |

| |

|

|

|

|

|

|

|

|

| yoke must be checked. |

| |||

|

|

|

|

|

|

|

|

|

|

| |||

| Air leaking between hous- |

|

| 1. Loose screws in housing. |

|

| 1. | Tighten screws. |

|

| |||

| ing and hose. |

|

| 2. Damaged |

|

| 2. | Replace |

|

| |||

|

|

|

| 3. | Loose air fitting. |

|

| 3. | Tighten air fitting. |

|

| ||

|

|

|

|

|

|

|

|

|

| ||||

| Air leaking between hous- |

|

| 1. Damaged seal. |

|

| 1. | Replace damaged seals. |

| ||||

| ing and cap assembly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Tool skips staples while dis- |

|

| 1. Air leaks. |

|

| 1. | Tighten screws and fit- |

| ||||

| charging. |

|

|

|

|

|

|

| tings. |

|

|

|

|

|

|

|

| 2. | Dirt in nose. |

|

| 2. | Clean nose. |

|

|

| |

|

|

|

| 3. | Dirt or damage prevents sta- |

|

| 3. | Clean | magazine | and |

| |

|

|

|

|

| ples from moving freely in |

|

|

| inspect/repair damage. |

| |||

|

|

|

|

| magazine. |

|

|

|

|

|

|

|

|

|

|

|

| 4. | Inadequate air flow to tool. |

|

| 4. | Check fitting, hose, com- |

| |||

|

|

|

|

|

|

|

|

| pressor & air pressure. |

| |||

|

|

|

| 5. | Worn |

|

| 5. | Replace piston |

| |||

|

|

|

|

| lack of lubrication. |

|

|

| Lubricate. |

|

|

| |

|

|

|

| 6. | Damaged |

|

| 6. | Replace trigger valve O- |

| |||

|

|

|

|

| valve. |

|

|

| rings. |

|

|

|

|

|

|

|

| 7. | Worn bumper. |

|

| 7. | Replace bumper. |

|

| ||

|

|

|

| 8. | Cap seal leaking. |

|

| 8. | Replace cap seal. |

|

| ||

|

|

|

|

|

|

|

|

|

|

| |||

| Tool runs slowly or has a |

|

| 1. Stapler is not sufficiently |

|

| 1. | Lubricate stapler. |

|

| |||

| loss of power. |

|

|

| lubricated. |

|

|

|

|

|

|

|

|

|

|

|

| 2. | Broken spring in cap assem- |

|

| 2. | Replace spring. |

|

| ||

|

|

|

|

| bly. |

|

|

|

|

|

|

|

|

|

|

|

| 3. | Exhaust port in cap is |

|

| 3. | Clean or replace dam- |

| |||

|

|

|

|

| blocked. |

|

|

| aged internal parts. |

| |||

|

|

|

|

|

|

|

|

|

| ||||

| Fasteners frequently jam |

|

| 1. Staples are the wrong size. |

|

| 1. | Use correct staples. |

| ||||

| the stapler. |

|

| 2. Staples are bent. |

|

| 2. | Use undamaged staples |

| ||||

|

|

|

| 3. | Magazine or nose screws |

|

| 3. | Tighten magazine and |

| |||

|

|

|

|

| are loose. |

|

|

| nose screws. |

|

|

| |

|

|

|

| 4. | Driver or driver guide are |

|

| 4. | Replace worn or dam- |

| |||

|

|

|

|

| worn or damaged. |

|

|

| aged parts. |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| ||

| Stapler does not fire. |

|

| 1. Staple is jammed in mag- |

|

| 1. | Clear | stapler | magazine |

| ||

|

|

|

|

| azine or discharge area. |

|

|

| or discharge area. |

|

| ||

|

|

|

| 2. Piston shaft is damaged. |

|

| 2. | Replace piston shaft. |

| ||||

|

|

|

| 3. Air pressure too low. |

|

| 3. | Check/increase air pres- |

| ||||

|

|

|

|

|

|

|

|

| sure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G6042/3 18 Gauge Stapler Kit |