Replacing Pistons/O-Rings

If you use your nailer day in and day out, Grizzly offers repair pistons as cheap insurance against wasted down time and lost profits in the event that a piston or pis- ton shaft becomes worn out. To replace a piston:

Always disconnect air from nailer whenever servicing! During mainte- nance, a nailer connected to air may fire accidentally, causing serious personal injury!

1.Disconnect the nailer from the air supply!

2.Remove all nails from the magazine cartridge.

3.Remove the 4 cap screws from the nailer exhaust cap.

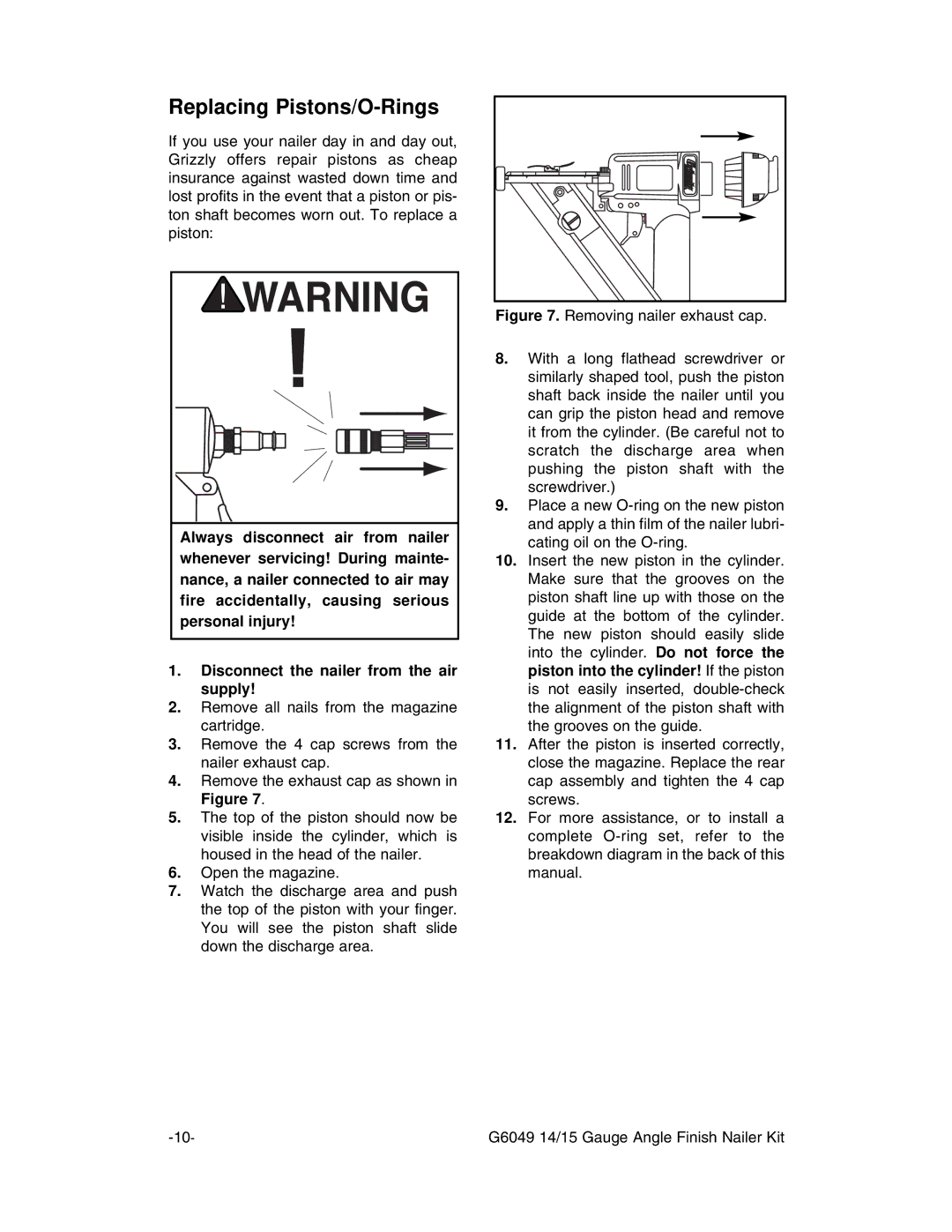

4.Remove the exhaust cap as shown in Figure 7.

5.The top of the piston should now be visible inside the cylinder, which is housed in the head of the nailer.

6.Open the magazine.

7.Watch the discharge area and push the top of the piston with your finger. You will see the piston shaft slide down the discharge area.

Figure 7. Removing nailer exhaust cap.

8.With a long flathead screwdriver or similarly shaped tool, push the piston shaft back inside the nailer until you can grip the piston head and remove it from the cylinder. (Be careful not to scratch the discharge area when pushing the piston shaft with the screwdriver.)

9.Place a new O-ring on the new piston and apply a thin film of the nailer lubri- cating oil on the O-ring.

10.Insert the new piston in the cylinder. Make sure that the grooves on the piston shaft line up with those on the guide at the bottom of the cylinder. The new piston should easily slide into the cylinder. Do not force the piston into the cylinder! If the piston is not easily inserted, double-check the alignment of the piston shaft with the grooves on the guide.

11.After the piston is inserted correctly, close the magazine. Replace the rear cap assembly and tighten the 4 cap screws.

12.For more assistance, or to install a complete O-ring set, refer to the breakdown diagram in the back of this manual.

G6049 14/15 Gauge Angle Finish Nailer Kit |