Operating Stapler

If you have not read the safety instruc- tions in this manual, do not operate the stapler.

Before the first operation, and periodically |

| |||

after that, place one drop of the included oil |

| |||

into the quick connect fitting where the sta- |

| |||

pler connects to the air supply. After oiling, |

| |||

wipe | off any excess oil near | the stapler | Figure 4. Example of staple deflection. | |

exhaust to avoid dust |

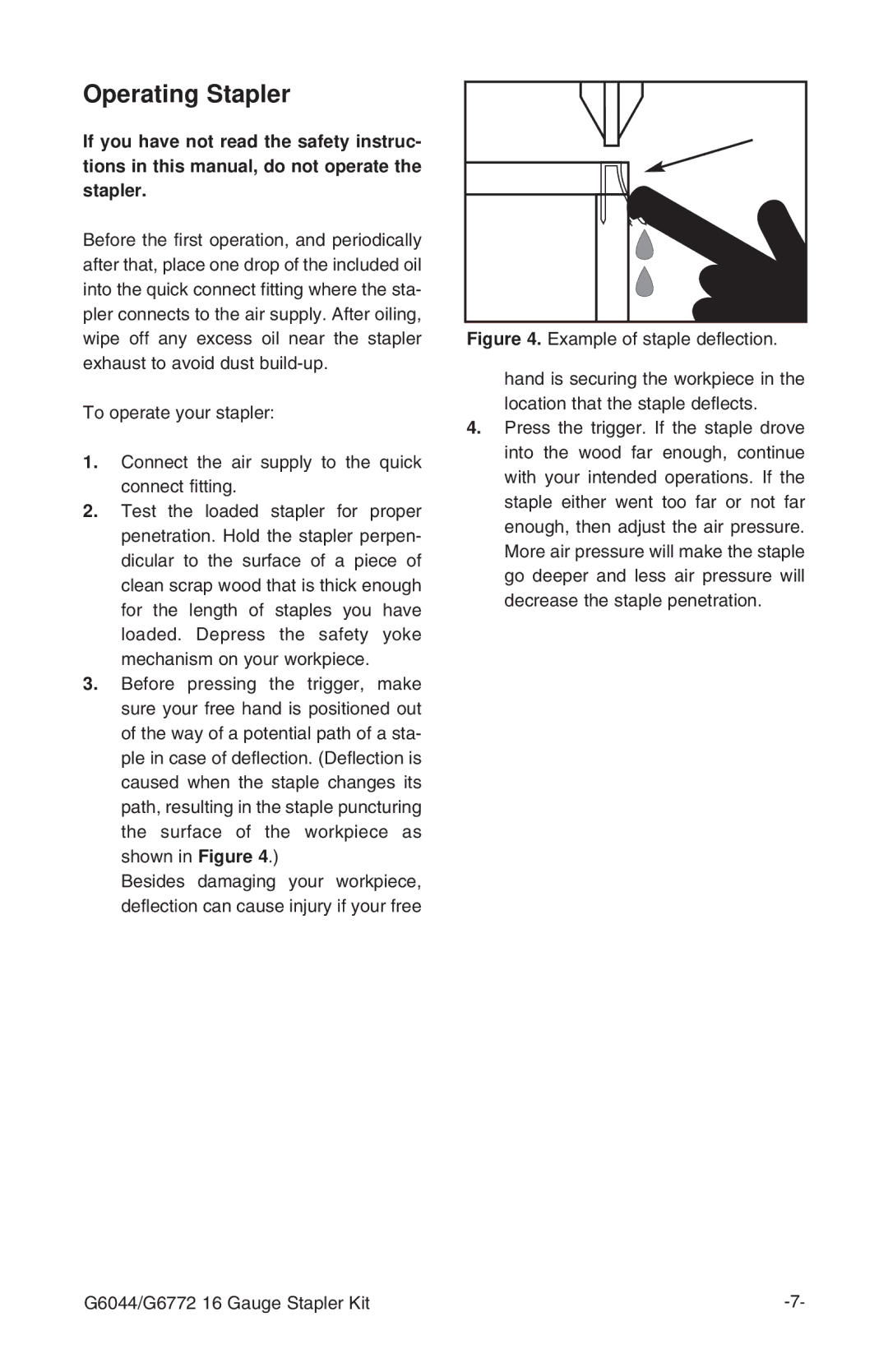

| hand is securing the workpiece in the | ||

|

|

| ||

To operate your stapler: |

| location that the staple deflects. | ||

| 4. Press the trigger. If the staple drove | |||

|

|

| ||

1. | Connect the air supply to the quick | into the wood far enough, continue | ||

with your intended operations. If the | ||||

| connect fitting. |

| ||

|

| staple either went too far or not far | ||

2. | Test the loaded stapler for proper | |||

enough, then adjust the air pressure. | ||||

| penetration. Hold the stapler perpen- | |||

| More air pressure will make the staple | |||

| dicular to the surface of a piece of | |||

| go deeper and less air pressure will | |||

| clean scrap wood that is thick enough | |||

| decrease the staple penetration. | |||

| for the length of staples you have | |||

|

| |||

| loaded. Depress the safety yoke |

| ||

| mechanism on your workpiece. |

| ||

3. Before pressing the trigger, make |

| |||

| sure your free hand is positioned out |

| ||

| of the way of a potential path of a sta- |

| ||

| ple in case of deflection. (Deflection is |

| ||

| caused when the staple changes its |

| ||

| path, resulting in the staple puncturing |

| ||

| the surface of the workpiece as |

| ||

| shown in Figure 4.) |

|

| |

| Besides damaging your | workpiece, |

| |

deflection can cause injury if your free

G6044/G6772 16 Gauge Stapler Kit |