Safety Instructions For Metalworking Tools

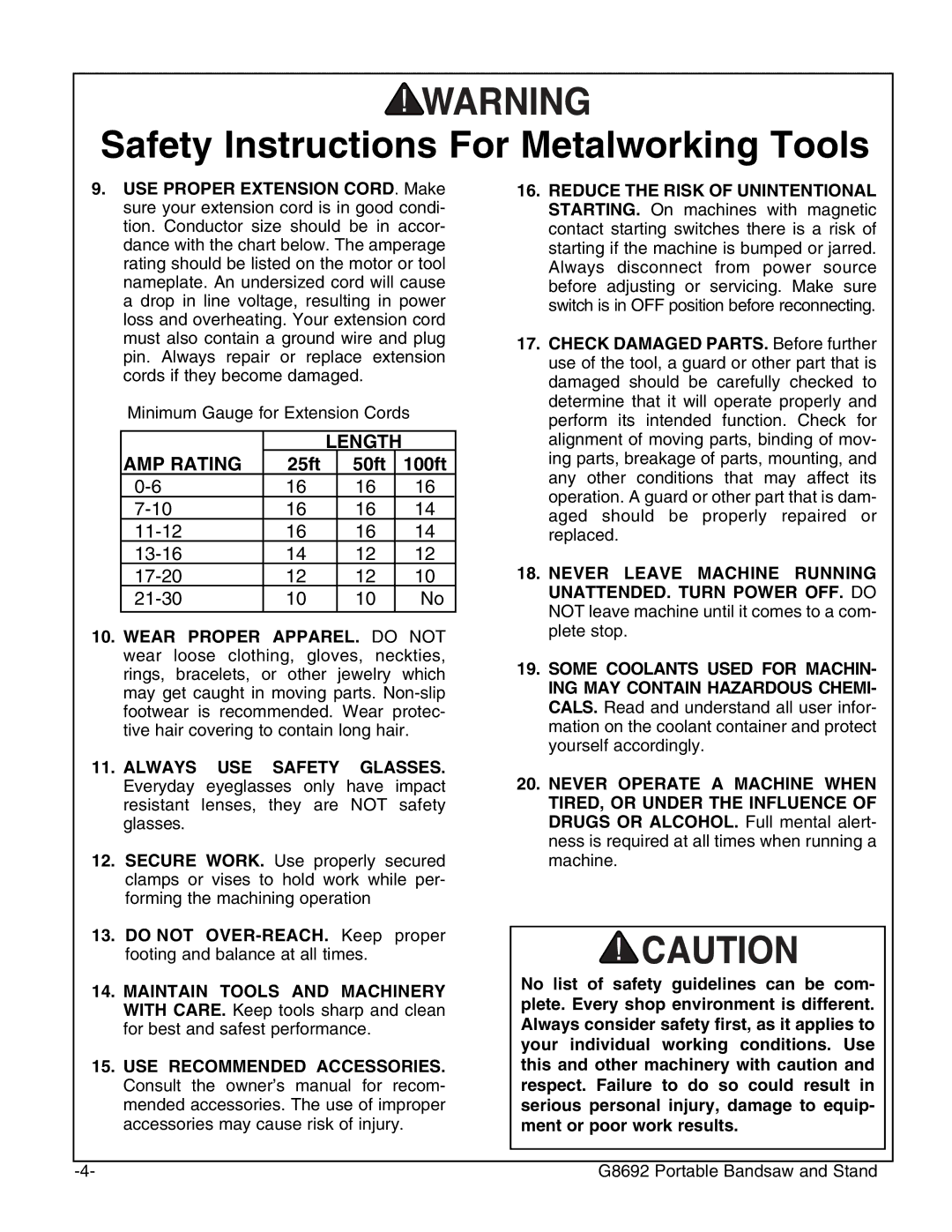

9.USE PROPER EXTENSION CORD. Make sure your extension cord is in good condi- tion. Conductor size should be in accor- dance with the chart below. The amperage rating should be listed on the motor or tool nameplate. An undersized cord will cause a drop in line voltage, resulting in power loss and overheating. Your extension cord must also contain a ground wire and plug pin. Always repair or replace extension cords if they become damaged.

Minimum Gauge for Extension Cords

|

| LENGTH |

| ||

AMP RATING | 25ft |

| 50ft |

| 100ft |

16 |

| 16 |

| 16 | |

16 |

| 16 |

| 14 | |

| 16 |

| 16 |

| 14 |

| 14 |

| 12 |

| 12 |

| 12 |

| 12 |

| 10 |

| 10 |

| 10 |

| No |

|

|

|

|

|

|

10.WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which may get caught in moving parts.

11.ALWAYS USE SAFETY GLASSES. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

12.SECURE WORK. Use properly secured clamps or vises to hold work while per- forming the machining operation

16.REDUCE THE RISK OF UNINTENTIONAL STARTING. On machines with magnetic contact starting switches there is a risk of starting if the machine is bumped or jarred. Always disconnect from power source before adjusting or servicing. Make sure switch is in OFF position before reconnecting.

17.CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of mov- ing parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is dam- aged should be properly repaired or replaced.

18.NEVER LEAVE MACHINE RUNNING UNATTENDED. TURN POWER OFF. DO NOT leave machine until it comes to a com- plete stop.

19.SOME COOLANTS USED FOR MACHIN- ING MAY CONTAIN HAZARDOUS CHEMI- CALS. Read and understand all user infor- mation on the coolant container and protect yourself accordingly.

20.NEVER OPERATE A MACHINE WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL. Full mental alert- ness is required at all times when running a machine.

13.DO NOT

14.MAINTAIN TOOLS AND MACHINERY WITH CARE. Keep tools sharp and clean for best and safest performance.

15.USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recom- mended accessories. The use of improper accessories may cause risk of injury.

No list of safety guidelines can be com- plete. Every shop environment is different. Always consider safety first, as it applies to your individual working conditions. Use this and other machinery with caution and respect. Failure to do so could result in serious personal injury, damage to equip- ment or poor work results.

G8692 Portable Bandsaw and Stand |