OPERATION & ADJUSTMENTS

Angle Adjustments

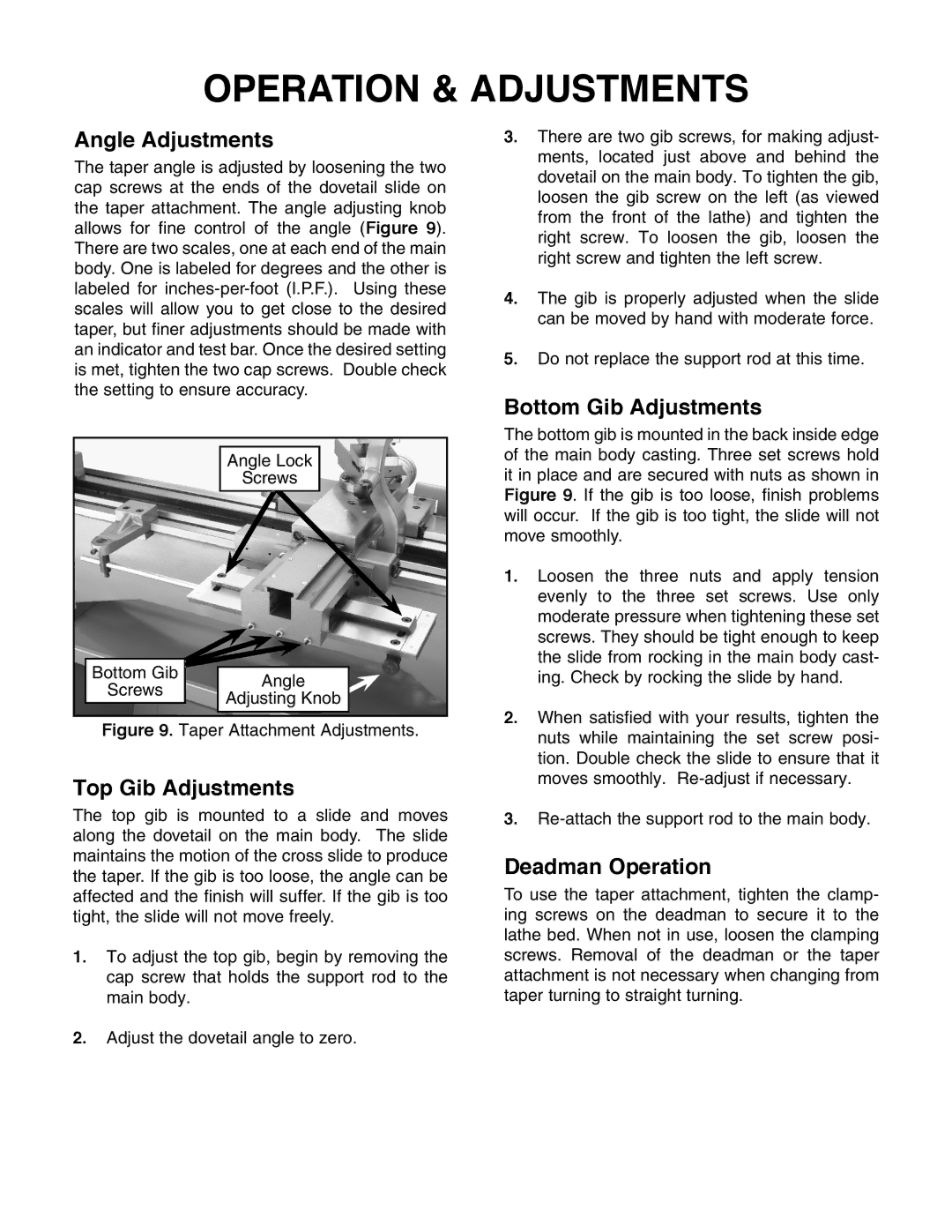

The taper angle is adjusted by loosening the two cap screws at the ends of the dovetail slide on the taper attachment. The angle adjusting knob allows for fine control of the angle ( Figure 9). There are two scales, one at each end of the main body. One is labeled for degrees and the other is labeled for

Angle Lock

Screws

Bottom Gib | Angle | |

Screws | ||

Adjusting Knob | ||

|

Figure 9. Taper Attachment Adjustments.

Top Gib Adjustments

The top gib is mounted to a slide and moves along the dovetail on the main body. The slide maintains the motion of the cross slide to produce the taper. If the gib is too loose, the angle can be affected and the finish will suffer. If the gib is too tight, the slide will not move freely.

1.To adjust the top gib, begin by removing the cap screw that holds the support rod to the main body.

3.There are two gib screws, for making adjust- ments, located just above and behind the dovetail on the main body. To tighten the gib, loosen the gib screw on the left (as viewed from the front of the lathe) and tighten the right screw. To loosen the gib, loosen the right screw and tighten the left screw.

4.The gib is properly adjusted when the slide can be moved by hand with moderate force.

5.Do not replace the support rod at this time.

Bottom Gib Adjustments

The bottom gib is mounted in the back inside edge of the main body casting. Three set screws hold it in place and are secured with nuts as shown in Figure 9 If the gib is too loose, finish problems will occur. If the gib is too tight, the slide will not move smoothly.

1.Loosen the three nuts and apply tension evenly to the three set screws. Use only moderate pressure when tightening these set screws. They should be tight enough to keep the slide from rocking in the main body cast- ing. Check by rocking the slide by hand.

2.When satisfied with your results, tighten the nuts while maintaining the set screw posi- tion. Double check the slide to ensure that it moves smoothly.

3.

Deadman Operation

To use the taper attachment, tighten the clamp- ing screws on the deadman to secure it to the lathe bed. When not in use, loosen the clamping screws. Removal of the deadman or the taper attachment is not necessary when changing from taper turning to straight turning.

2.Adjust the dovetail angle to zero.