OPERATIONS

Installing Bits

The Model H6155 uses bits and cutters with a 1⁄8" diameter shaft. See the Grizzly catalog or website for a complete listing of available bits and accessories.

DO NOT use bits or cutters with a cutting surface larger than 1". The bit could break apart under the stresses of high speed use caus- ing serious personal injury.

To install a bit:

1.Unplug the tool from the power source!

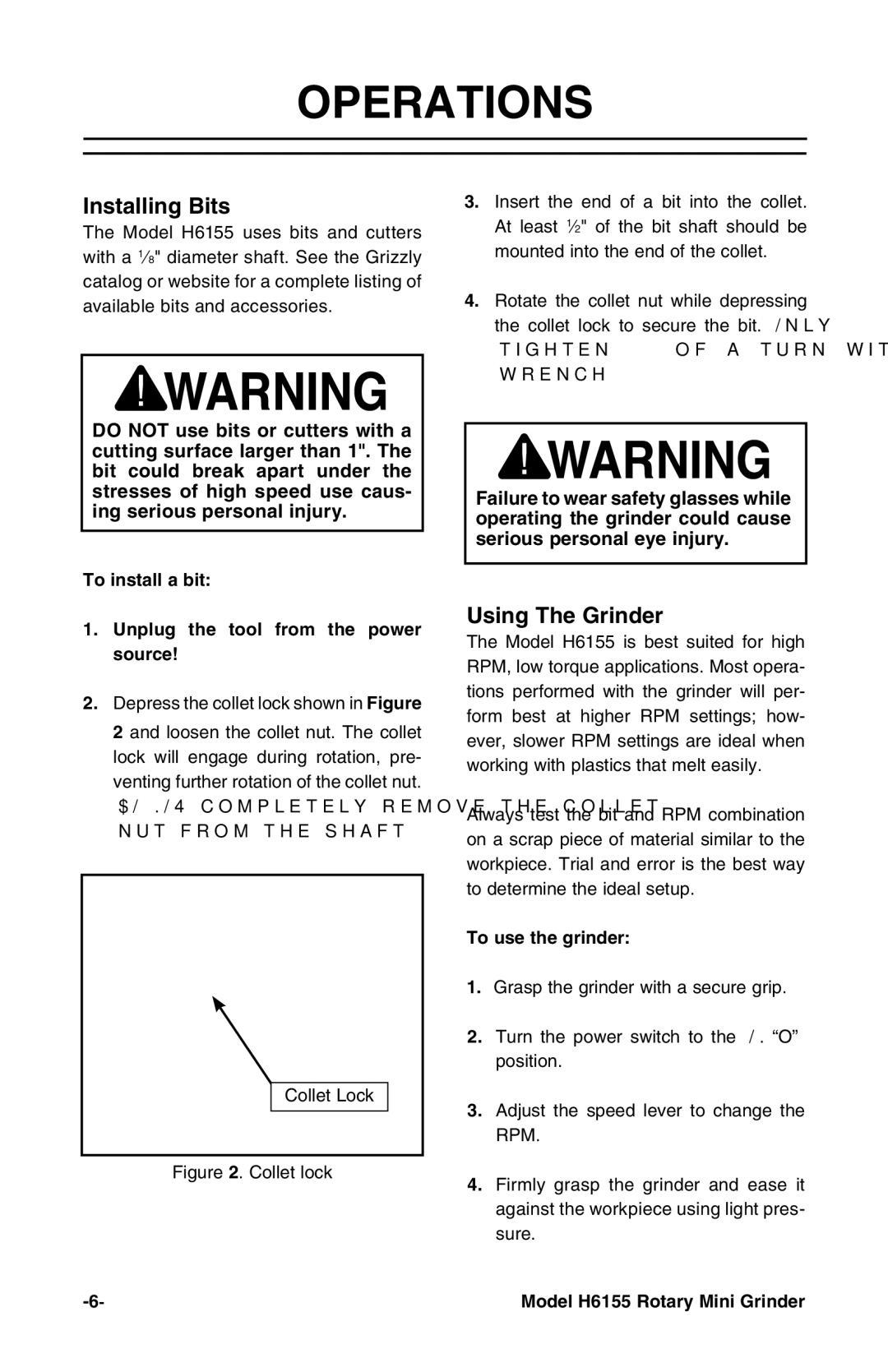

2.Depress the collet lock shown in Figure 2 and loosen the collet nut. The collet lock will engage during rotation, pre- venting further rotation of the collet nut. DO NOT completely remove the collet nut from the shaft.

Collet Lock

Figure 2. Collet lock

3.Insert the end of a bit into the collet. At least 1⁄2" of the bit shaft should be mounted into the end of the collet.

4.Rotate the collet nut while depressing the collet lock to secure the bit. Only tighten 1/3 of a turn with the collet wrench.

Failure to wear safety glasses while operating the grinder could cause serious personal eye injury.

Using The Grinder

The Model H6155 is best suited for high RPM, low torque applications. Most opera- tions performed with the grinder will per- form best at higher RPM settings; how- ever, slower RPM settings are ideal when working with plastics that melt easily.

Always test the bit and RPM combination on a scrap piece of material similar to the workpiece. Trial and error is the best way to determine the ideal setup.

To use the grinder:

1.Grasp the grinder with a secure grip.

2.Turn the power switch to the ON “O” position.

3.Adjust the speed lever to change the RPM.

4.Firmly grasp the grinder and ease it against the workpiece using light pres- sure.

Model H6155 Rotary Mini Grinder |