AssemblyControls

1.Insert the filter into the gun body (see Figure 2).

Figure 2. Installing filter.

2.Screw the cup onto the top of the body.

3.Install the barbed hose fitting into the base of the gun handle and tighten in place with the lock nut.

4.Secure the air hose to the barbed fit- ting with a hose clamp.

Note: Using a 1⁄4" NPS quick discon- nect

5.Attach the spray gun to an air hose regulated between 43.5 and 58 PSI.

Note: For the best results, use a hose that will be dedicated for spray use only. Do not use a hose that has been used with an

If you need additional help with this assem- bly, call our Technical Support at: (570)

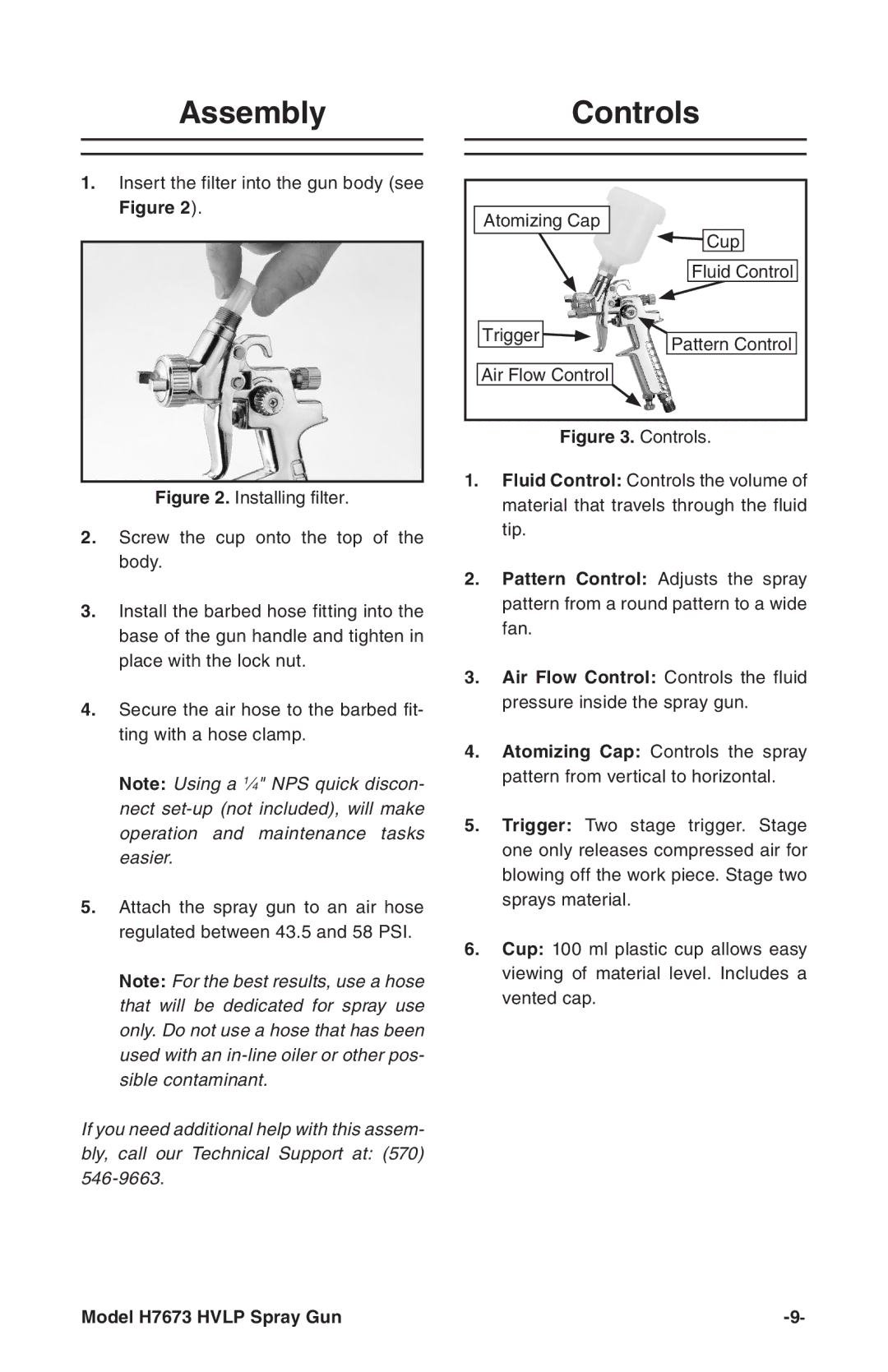

Atomizing Cap |

|

| Cup |

| Fluid Control |

Trigger | Pattern Control |

| |

Air Flow Control |

|

Figure 3. Controls.

1.Fluid Control: Controls the volume of material that travels through the fluid tip.

2.Pattern Control: Adjusts the spray pattern from a round pattern to a wide fan.

3.Air Flow Control: Controls the fluid pressure inside the spray gun.

4.Atomizing Cap: Controls the spray pattern from vertical to horizontal.

5.Trigger: Two stage trigger. Stage one only releases compressed air for blowing off the work piece. Stage two sprays material.

6.Cup: 100 ml plastic cup allows easy viewing of material level. Includes a vented cap.

Model H7673 HVLP Spray Gun |