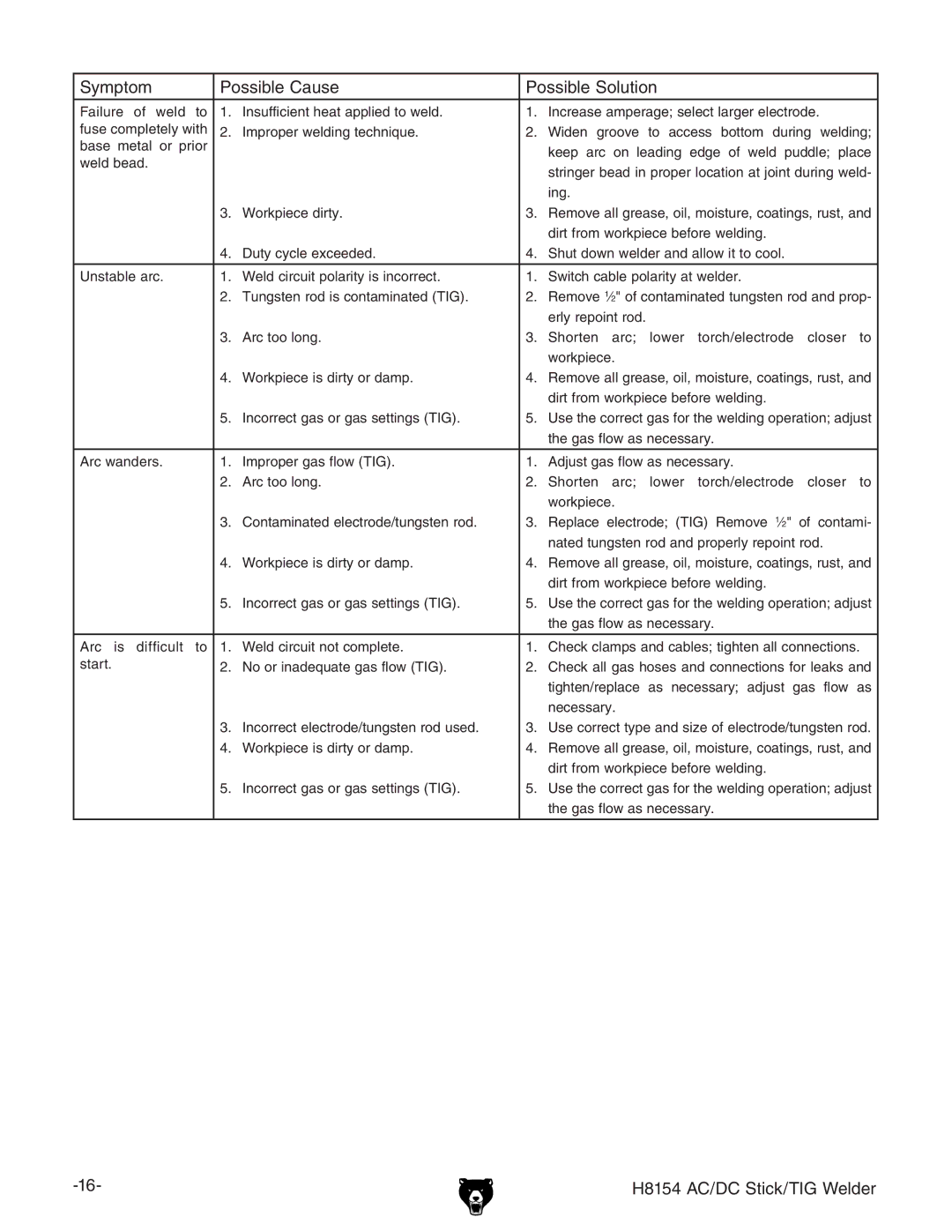

Symptom |

| Possible Cause | Possible Solution |

| |||

Failure | of weld | to | 1. | Insufficient heat applied to weld. | 1. | Increase amperage; select larger electrode. | |

fuse completely with | 2. | Improper welding technique. | 2. | Widen groove to access | bottom during welding; | ||

base metal or prior |

|

|

| keep arc on leading edge | of weld puddle; place | ||

weld bead. |

|

|

|

| |||

|

|

|

| stringer bead in proper location at joint during weld- | |||

|

|

|

|

|

| ||

|

|

|

|

|

| ing. |

|

|

|

| 3. | Workpiece dirty. | 3. | Remove all grease, oil, moisture, coatings, rust, and | |

|

|

|

|

|

| dirt from workpiece before welding. | |

|

|

| 4. | Duty cycle exceeded. | 4. | Shut down welder and allow it to cool. | |

|

|

|

|

|

| ||

Unstable arc. |

| 1. | Weld circuit polarity is incorrect. | 1. | Switch cable polarity at welder. | ||

|

|

| 2. | Tungsten rod is contaminated (TIG). | 2. | Remove 1⁄2" of contaminated tungsten rod and prop- | |

|

|

|

|

|

| erly repoint rod. |

|

|

|

| 3. | Arc too long. | 3. | Shorten arc; lower torch/electrode closer to | |

|

|

|

|

|

| workpiece. |

|

|

|

| 4. | Workpiece is dirty or damp. | 4. | Remove all grease, oil, moisture, coatings, rust, and | |

|

|

|

|

|

| dirt from workpiece before welding. | |

|

|

| 5. | Incorrect gas or gas settings (TIG). | 5. | Use the correct gas for the welding operation; adjust | |

|

|

|

|

|

| the gas flow as necessary. |

|

|

|

|

|

|

| ||

Arc wanders. |

| 1. | Improper gas flow (TIG). | 1. | Adjust gas flow as necessary. | ||

|

|

| 2. | Arc too long. | 2. | Shorten arc; lower torch/electrode closer to | |

|

|

|

|

|

| workpiece. |

|

|

|

| 3. | Contaminated electrode/tungsten rod. | 3. | Replace electrode; (TIG) Remove 1⁄2" of contami- | |

|

|

|

|

|

| nated tungsten rod and properly repoint rod. | |

|

|

| 4. | Workpiece is dirty or damp. | 4. | Remove all grease, oil, moisture, coatings, rust, and | |

|

|

|

|

|

| dirt from workpiece before welding. | |

|

|

| 5. | Incorrect gas or gas settings (TIG). | 5. | Use the correct gas for the welding operation; adjust | |

|

|

|

|

|

| the gas flow as necessary. |

|

|

|

|

|

|

|

| |

Arc is | difficult | to | 1. | Weld circuit not complete. | 1. | Check clamps and cables; tighten all connections. | |

start. |

|

| 2. | No or inadequate gas flow (TIG). | 2. | Check all gas hoses and connections for leaks and | |

|

|

|

|

|

| tighten/replace as necessary; adjust gas flow as | |

|

|

|

|

|

| necessary. |

|

|

|

| 3. | Incorrect electrode/tungsten rod used. | 3. | Use correct type and size of electrode/tungsten rod. | |

|

|

| 4. | Workpiece is dirty or damp. | 4. | Remove all grease, oil, moisture, coatings, rust, and | |

|

|

|

|

|

| dirt from workpiece before welding. | |

|

|

| 5. | Incorrect gas or gas settings (TIG). | 5. | Use the correct gas for the welding operation; adjust | |

|

|

|

|

|

| the gas flow as necessary. |

|

|

|

|

|

|

|

|

|

H8154 AC/DC Stick/TIG Welder |