H8181 specifications

Grizzly H8181 is a powerful and versatile milling machine designed for both hobbyists and professional woodworkers. This machine is particularly well-regarded for its blend of precision, durability, and ease of use, making it an ideal addition to any workshop.One of the standout features of the Grizzly H8181 is its heavy-duty construction. Built with a cast iron base, the H8181 provides stability and minimizes vibration during operation. This robust construction not only enhances its longevity but also ensures that users achieve consistent results even when working on intricate projects.

In terms of specifications, the H8181 boasts a 1 HP motor that provides ample power for a variety of milling tasks. It has a variable speed range, allowing operators to adjust the RPM to suit the specific material and cutting requirements. This flexibility is a significant advantage, particularly when transitioning between different types of wood or composite materials.

The machine is equipped with a spacious worktable that is conveniently adjustable. This feature allows for greater versatility in handling various workpieces, accommodating both small and larger materials effectively. Additionally, the table’s T-slot design facilitates the use of jigs and fixtures, enabling more complex operations like raised panel cuts or precise mortising.

Another significant aspect of the Grizzly H8181 is its user-friendly interface. The controls are straightforward, making it accessible for users with varying degrees of experience. The machine also includes safety features such as an emergency stop button, which provides peace of mind during operation.

Technologically, the Grizzly H8181 employs a high-quality spindle system that ensures precise and smooth cutting. This system is crucial for achieving fine detail and accuracy, which is especially important in woodworking applications where precision is key.

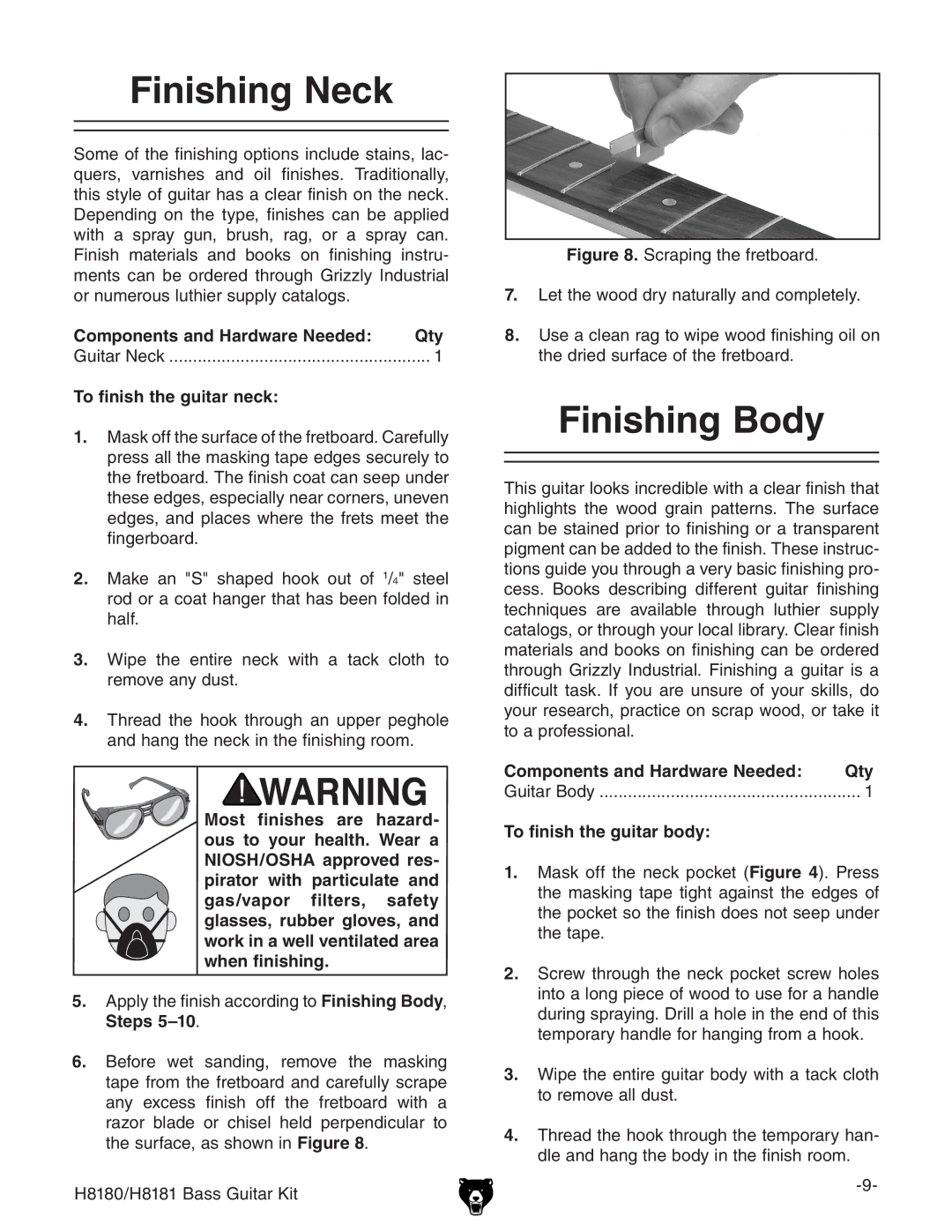

Overall, the Grizzly H8181 milling machine is an impressive piece of equipment that combines power, precision, and user-friendly features. Its heavy-duty construction, adjustable worktable, variable speed motor, and quality spindle make it an excellent choice for woodworkers looking for a reliable and efficient milling machine. Whether for hobbyist projects or professional-grade work, the H8181 stands out in its category, providing exceptional performance and versatility.