4.Separate the two pieces of the mounting assembly, then place the table bracket over the lip of the table trough, as shown in Figure 5.

Table

Bracket ![]()

Figure 5. Table bracket mounted on the lip of

the table trough.

5.Mark the points on the table where the table bracket hex bolts make contact, then remove the bracket from the table.

6.Spot drill the points marked in Step 5 to give the hex bolts a small spot to "bite" the table without slipping on the rough cast surface.

7.Set the bracket back on the table and tighten down the hex bolts.

8.Install the mounting bracket onto the power feed assembly with the two cap screws pro- vided, as shown in Figure 6, but do not yet fully tighten them.

Electrical

Plugs

Mounting

Bracket

Figure 6. Mounting bracket installed onto the

power feed unit.

H8370 Power Feed for Mill/Drills

9.Connect the electrical plugs of the mounting bracket and power feed.

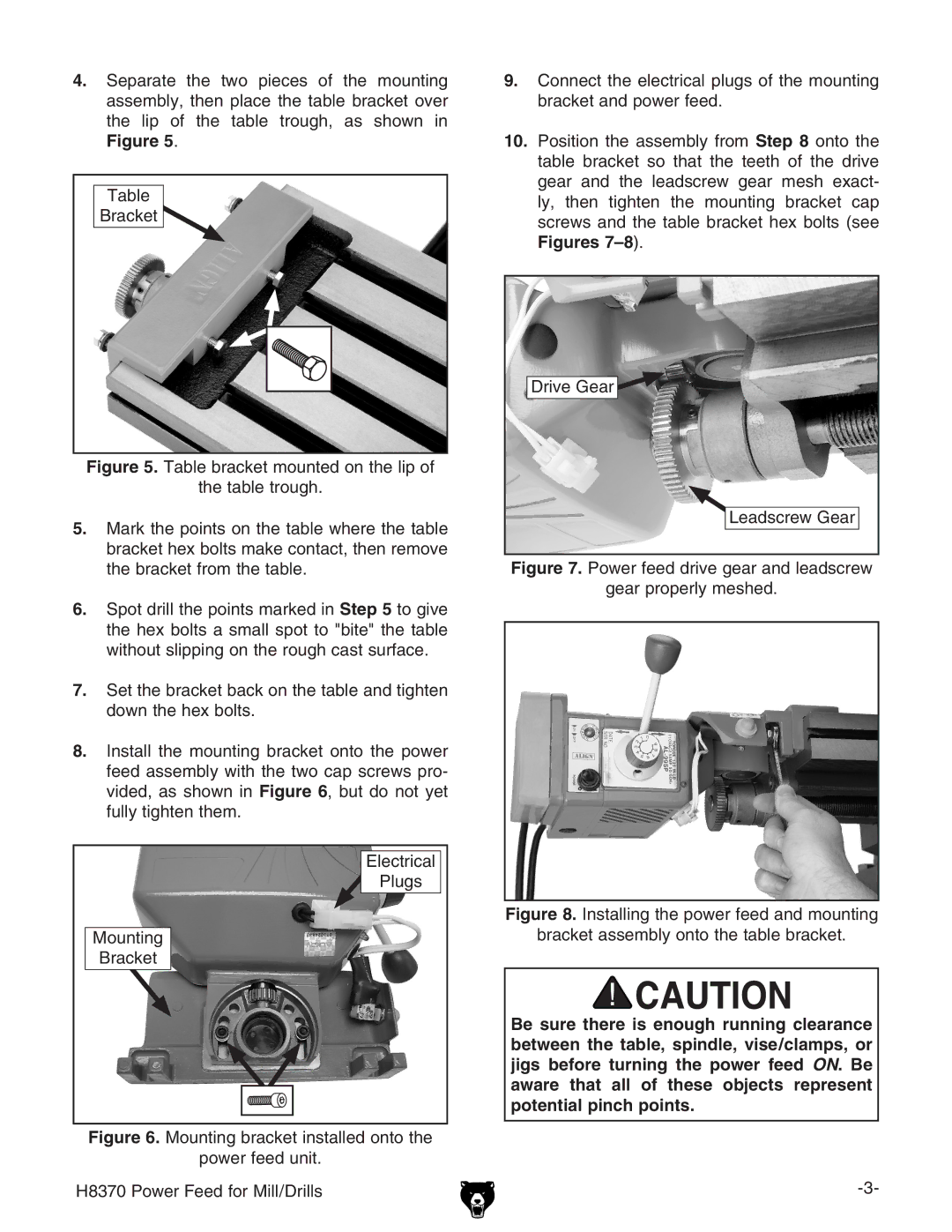

10.Position the assembly from Step 8 onto the table bracket so that the teeth of the drive gear and the leadscrew gear mesh exact- ly, then tighten the mounting bracket cap screws and the table bracket hex bolts (see Figures 7–8).

Drive Gear

Leadscrew Gear

Figure 7. Power feed drive gear and leadscrew

gear properly meshed.

Figure 8. Installing the power feed and mounting

bracket assembly onto the table bracket.

Be sure there is enough running clearance between the table, spindle, vise/clamps, or jigs before turning the power feed ON. Be aware that all of these objects represent potential pinch points.