Safety Instructions For Power Tools

9. |

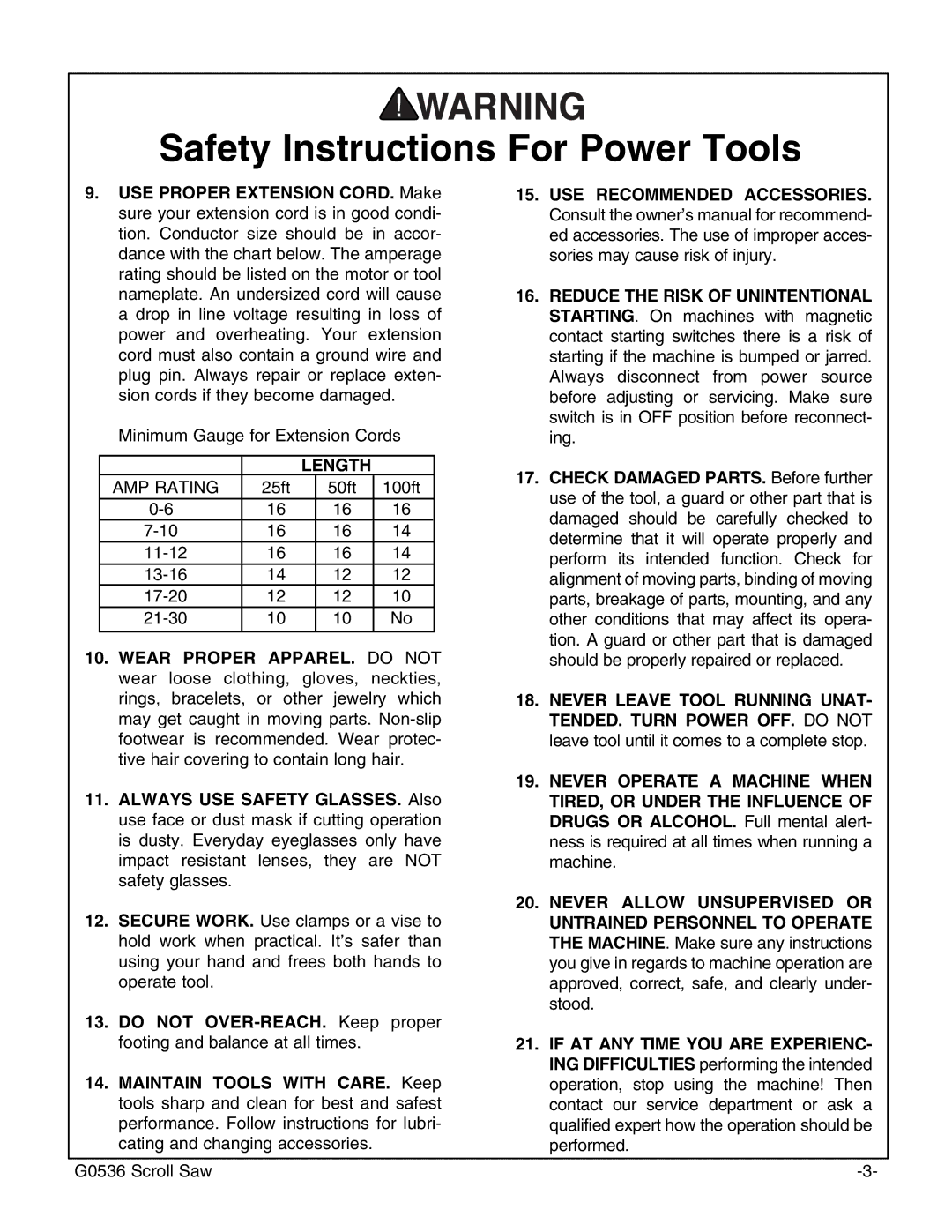

| USE PROPER EXTENSION CORD. Make | 15. USE RECOMMENDED ACCESSORIES. | ||||||

|

| sure your extension cord is in good condi- | Consult the owner’s manual for recommend- | ||||||

|

| tion. Conductor size should be in accor- | ed accessories. The use of improper acces- | ||||||

|

| dance with the chart below. The amperage | sories may cause risk of injury. | ||||||

|

| rating should be listed on the motor or tool |

| ||||||

|

| nameplate. An undersized cord will cause | 16. REDUCE THE RISK OF UNINTENTIONAL | ||||||

|

| a drop in line voltage resulting in loss of | STARTING. On machines with magnetic | ||||||

|

| power and overheating. Your extension | contact starting switches there is a risk of | ||||||

|

| cord must also contain a ground wire and | starting if the machine is bumped or jarred. | ||||||

|

| plug pin. Always repair or replace exten- | Always disconnect from power source | ||||||

|

| sion cords if they become damaged. | before adjusting or servicing. Make sure | ||||||

|

| Minimum Gauge for Extension Cords | switch is in OFF position before reconnect- | ||||||

|

| ing. | |||||||

|

|

|

|

|

|

|

|

| |

|

|

|

| LENGTH |

|

| 17. CHECK DAMAGED PARTS. Before further | ||

|

| AMP RATING | 25ft |

| 50ft | 100ft |

| ||

|

|

|

| use of the tool, a guard or other part that is | |||||

|

| 16 |

| 16 | 16 |

| |||

|

|

|

| damaged should be carefully checked to | |||||

|

| 16 |

| 16 | 14 |

| |||

|

|

|

| determine that it will operate properly and | |||||

|

| 16 |

| 16 | 14 |

| |||

|

|

|

| perform its intended function. Check for | |||||

|

| 14 |

| 12 | 12 |

| alignment of moving parts, binding of moving | ||

|

| 12 |

| 12 | 10 |

| parts, breakage of parts, mounting, and any | ||

|

| 10 |

| 10 | No |

| other conditions that may affect its opera- | ||

|

|

|

|

|

|

|

| tion. A guard or other part that is damaged | |

10. | WEAR PROPER APPAREL. DO NOT | ||||||||

should be properly repaired or replaced. | |||||||||

|

| wear loose clothing, gloves, neckties, |

| ||||||

|

| rings, bracelets, or other jewelry which | 18. NEVER LEAVE TOOL RUNNING UNAT- | ||||||

|

| may get caught in moving parts. | TENDED. TURN POWER OFF. DO NOT | ||||||

|

| footwear is recommended. Wear protec- | leave tool until it comes to a complete stop. | ||||||

|

| tive hair covering to contain long hair. |

| ||||||

11. | ALWAYS USE SAFETY GLASSES. Also | 19. NEVER OPERATE A MACHINE WHEN | |||||||

TIRED, OR UNDER THE INFLUENCE OF | |||||||||

|

| use face or dust mask if cutting operation | DRUGS OR ALCOHOL. Full mental alert- | ||||||

|

| is dusty. Everyday eyeglasses only have | ness is required at all times when running a | ||||||

|

| impact resistant lenses, they are NOT | machine. | ||||||

|

| safety glasses. |

|

|

|

|

|

| |

12. | SECURE WORK. Use clamps or a vise to | 20. NEVER ALLOW UNSUPERVISED OR | |||||||

UNTRAINED PERSONNEL TO OPERATE | |||||||||

|

| hold work when practical. It’s safer than | THE MACHINE. Make sure any instructions | ||||||

|

| using your hand and frees both hands to | you give in regards to machine operation are | ||||||

|

| operate tool. |

|

|

|

|

| approved, correct, safe, and clearly under- | |

13. | DO NOT | stood. | |||||||

| |||||||||

|

| footing and balance at all times. |

|

| 21. IF AT ANY TIME YOU ARE EXPERIENC- | ||||

14. | MAINTAIN TOOLS WITH CARE. Keep | ING DIFFICULTIES performing the intended | |||||||

operation, stop using the machine! Then | |||||||||

|

| tools sharp and clean for best and safest | contact our service department or ask a | ||||||

|

| performance. Follow instructions for lubri- | qualified expert how the operation should be | ||||||

|

| cating and changing accessories. |

|

| performed. | ||||

|

|

|

|

|

|

|

| ||

G0536 Scroll Saw |

|

|

|

|

| ||||