Lubrication

The Model G1033 features

Proper lubrication of other components of the Model G1033 are essential for long life and trou-

Columns/Lead Screws - The four columns should be lubricated weekly with light oil. Unfasten dust covers to gain access. The four lead screws should be lubricated with general purpose grease once a month.

Worm Gear - The worm gear should be inspect- ed monthly and lubricated when needed. Remove the worm gear box to inspect. See parts diagram for location.

Chain - The table height adjustment chain should be inspected monthly and lubricated when need- ed. A good quality bicycle chain lubricant works well for periodic lubrication.

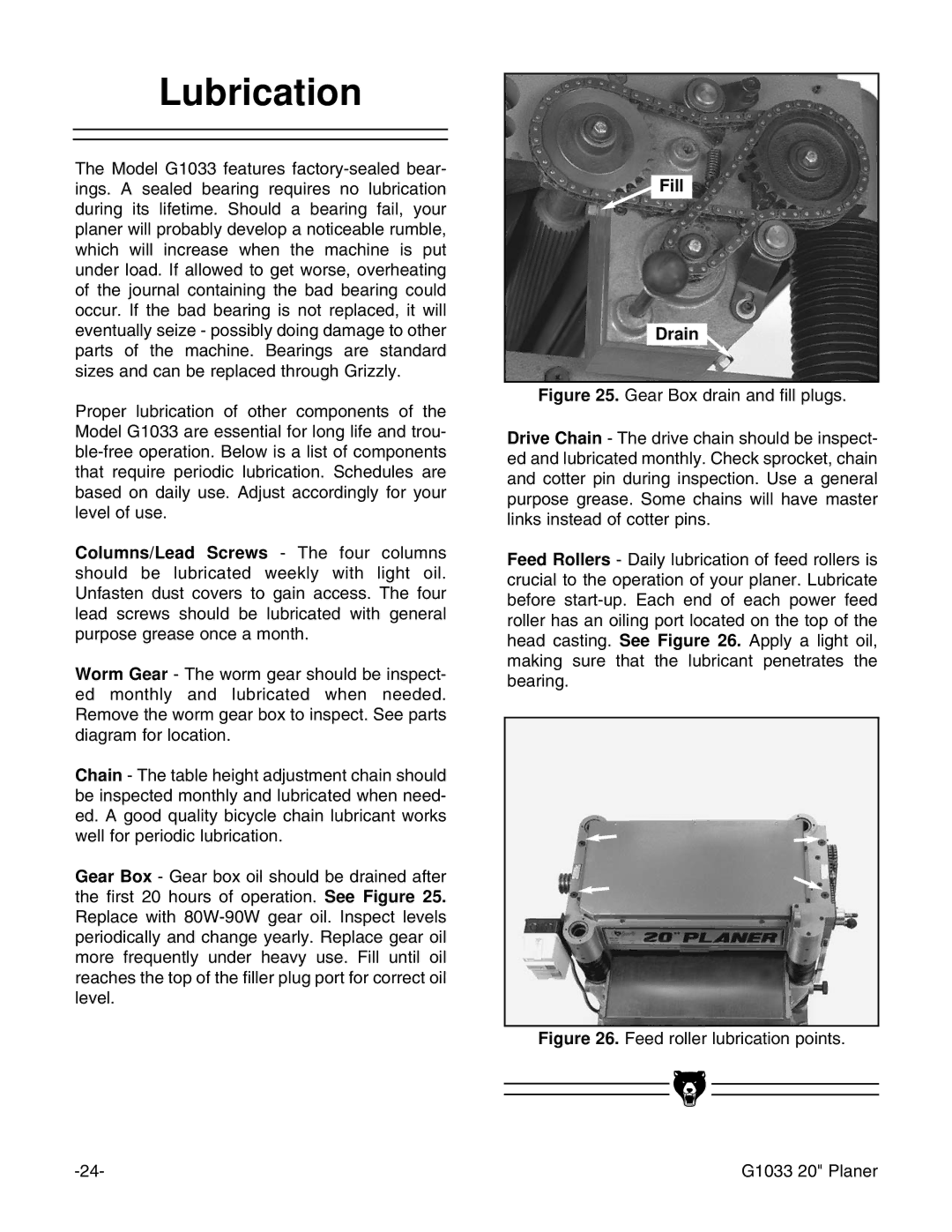

Gear Box - Gear box oil should be drained after the first 20 hours of operation. See Figure 25. Replace with

![]() Fill

Fill

Drain ![]()

Figure 25. Gear Box drain and fill plugs.

Drive Chain - The drive chain should be inspect- ed and lubricated monthly. Check sprocket, chain and cotter pin during inspection. Use a general purpose grease. Some chains will have master links instead of cotter pins.

Feed Rollers - Daily lubrication of feed rollers is crucial to the operation of your planer. Lubricate before start-up. Each end of each power feed roller has an oiling port located on the top of the head casting. See Figure 26. Apply a light oil, making sure that the lubricant penetrates the bearing.

Figure 26. Feed roller lubrication points.

|

|

|

|

|

|

|

|

|

| G1033 20" Planer | |

|

|